Direct-drive permanent magnet rotor with holders

A permanent magnet rotor and cage technology, which is applied to the rotating parts of the magnetic circuit, magnetic circuit, magnetic circuit shape/style/structure, etc., can solve the problems of large gaps, limited length, and permanent magnets that cannot be attached to the body, and achieve an optimized magnetic field Structure, low processing cost and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

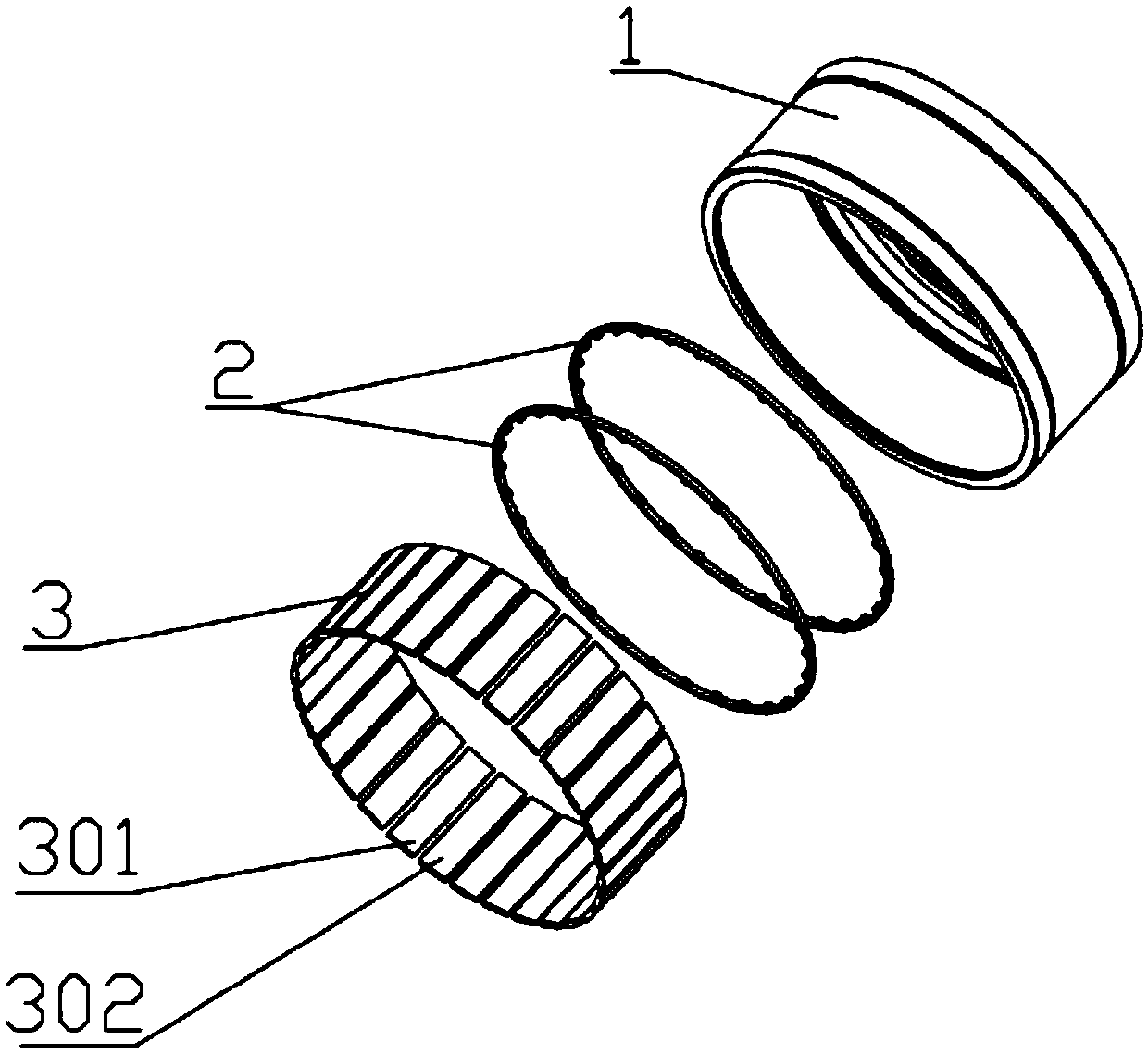

[0019] Considering the limited length of the current direct-drive motor rotor's turntable processing cogging, it is only suitable for short permanent magnets, and the processing cost is high. If the cogging is not processed, the last permanent magnet will not be attached, or it is better to post the last one. The gap is large and uneven, which affects the performance of the motor. In order to solve the above technical problems, the present invention proposes a direct-drive permanent magnet rotor with a cage.

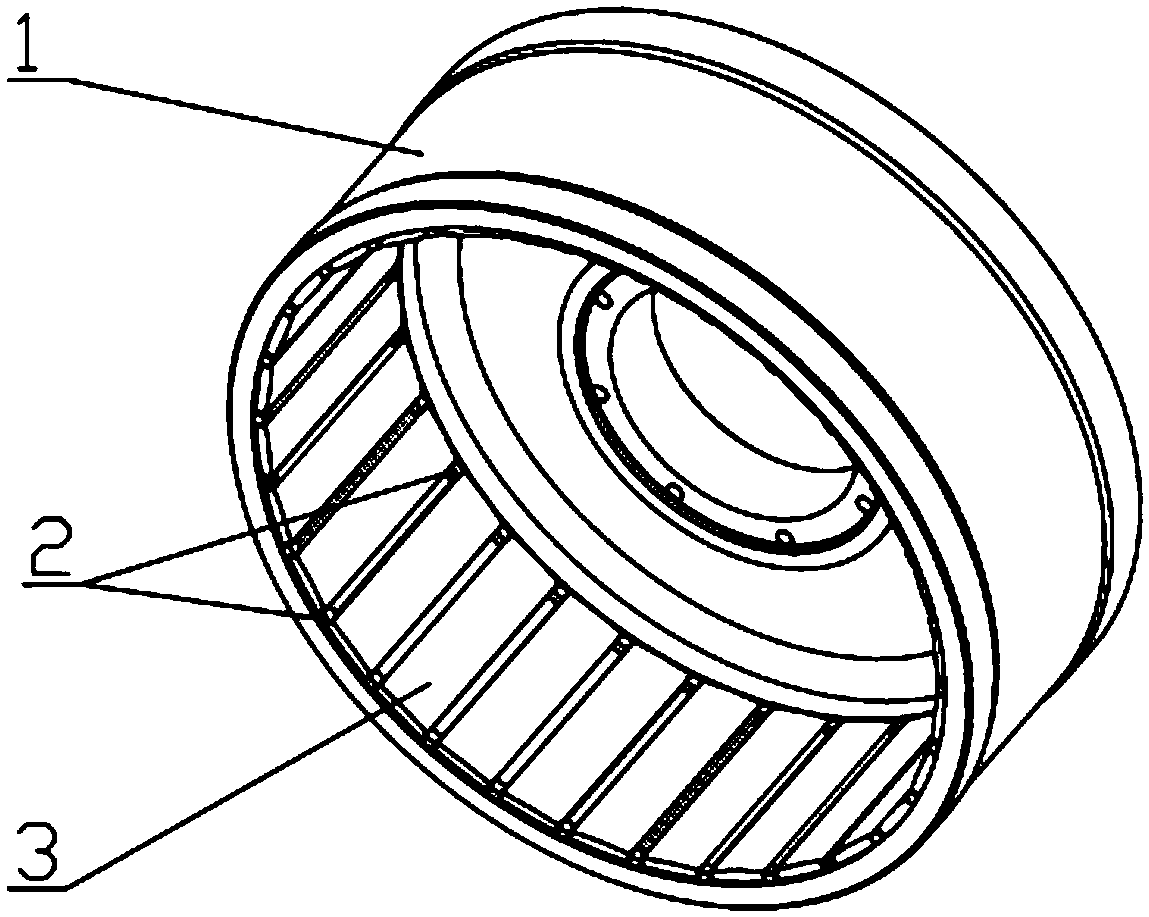

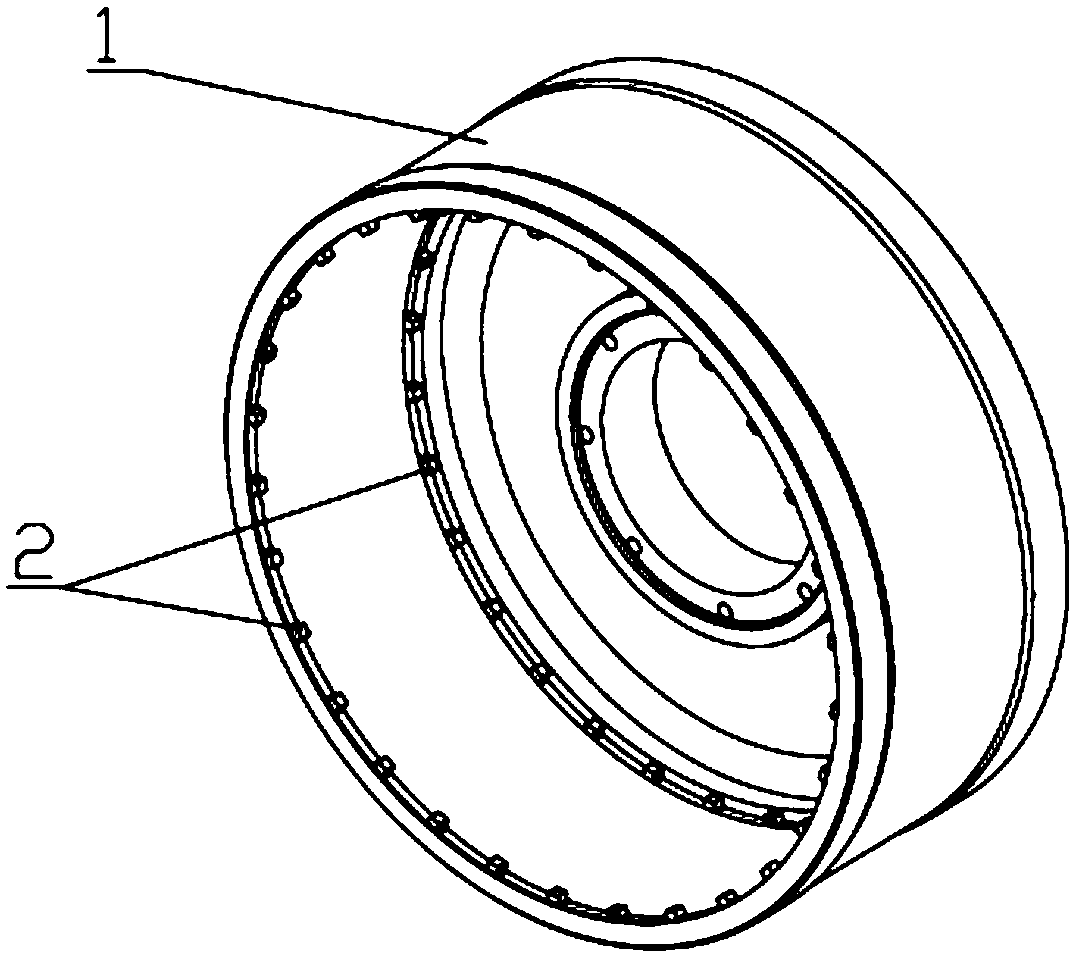

[0020] The technical solution adopted in the present invention mainly includes a turntable, a bracket assembly, and a permanent magnet assembly. Wherein, there are slots at both ends of the surface of the turntable attached to the permanent magnet; the bracket assembly has a tooth groove, which can be a full cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com