Carbon fiber composite multi-way connector

A technology of multi-way joints and composite materials, which is applied in the field of multi-way joints of carbon fiber composite materials, can solve the problem that branch pipes cannot be inserted into branch pipe joints, and achieve the effect of meeting complex load requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

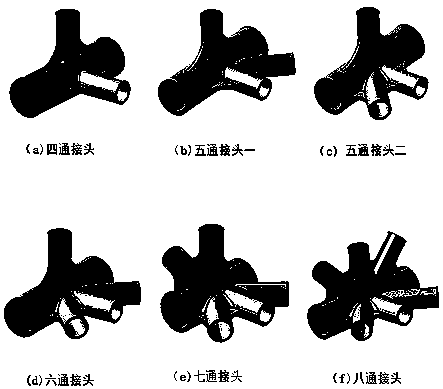

[0020] attached figure 1 There are five types of multi-way joints for carbon fiber composite materials, mainly including four-way joints, five-way joints, six-way joints, seven-way joints and eight-way joints.

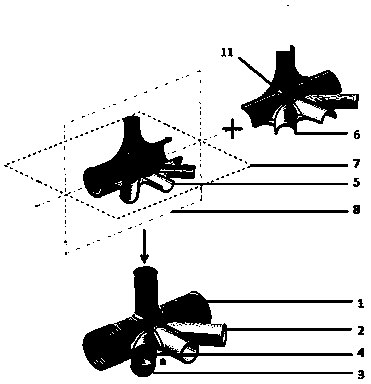

[0021] attached figure 2 It is a schematic diagram of the composition of the carbon fiber composite material six-way joint. A carbon fiber composite multi-way joint, the multi-way joint includes a main pipe joint 1 and four branch pipe joints 2, the main pipe joint 1 and the branch pipe joints 2 adopt a two-petal structure, the The branch pipe joints 2 are distributed on the side wall of the main pipe joint and communicate with the main pipe joint 1 as required, and one of the branch pipe joints 2 is arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com