Casting main frame of wind turbine generating set

A technology for wind turbines and main frames, which is applied to wind turbines, wind energy power generation, and the configuration of installing/supporting wind turbines, etc., can solve the problem of losing the cost advantage of the main frame, and achieve light weight, lower manufacturing costs, and simple processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

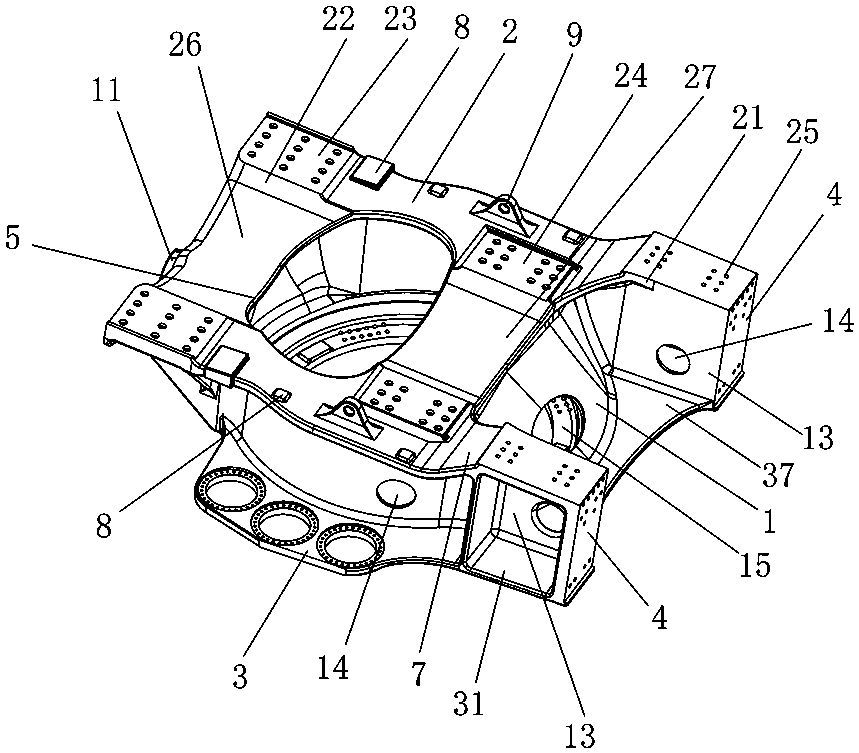

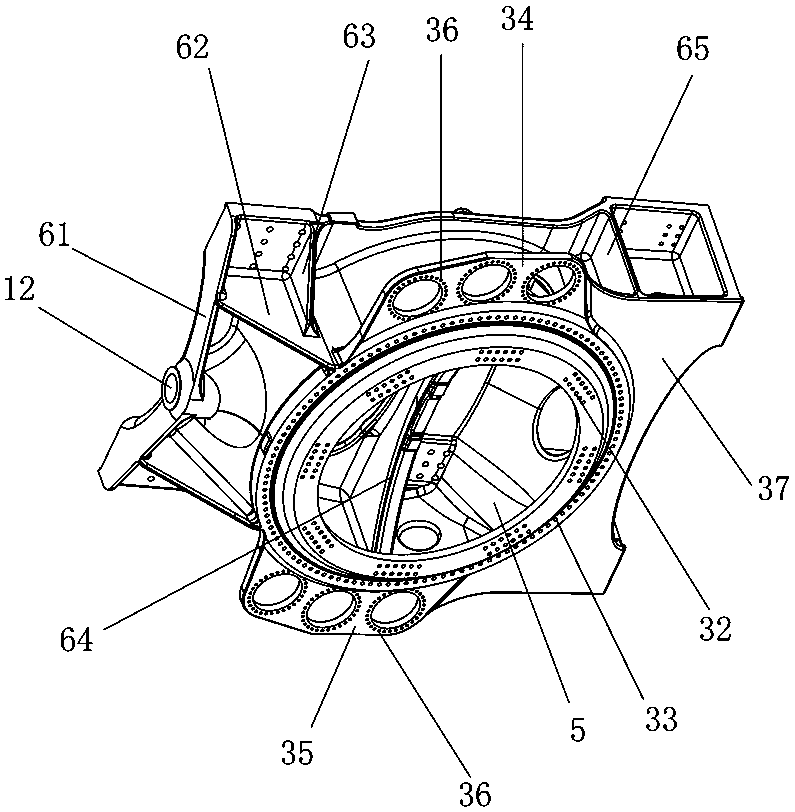

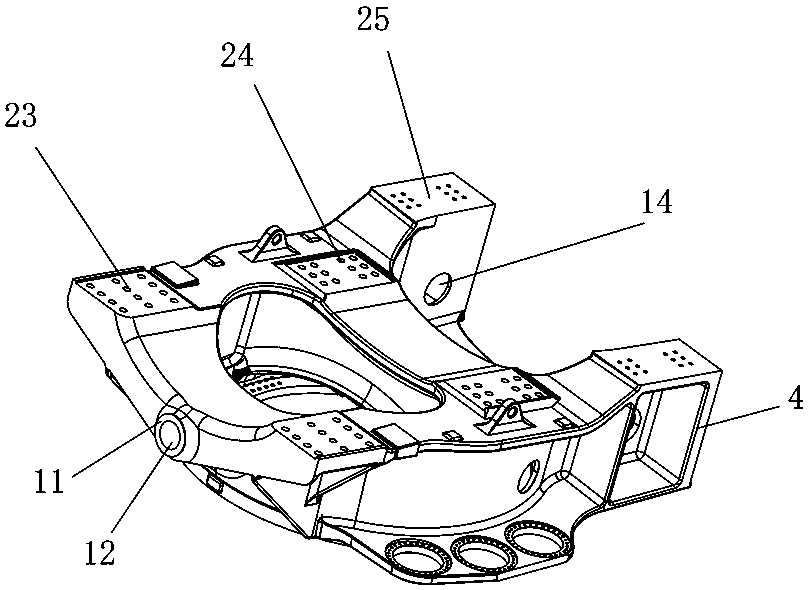

[0023] like Figure 1 to Figure 4 An embodiment of the present invention is shown. The cast main frame of the wind power generating set in this embodiment includes a hollow shell 1, a top plate 2 for connecting the mounting carrier of the main transmission chain, and a top plate 2 for connecting the mounting carrier of the yaw system. Bottom plate 3 and two rear end flanges 4 for connecting the rear frame, top plate 2 is arranged on the upper part of the housing 1, the bottom plate 3 is arranged on the lower part of the housing 1, and the front part of the housing 1 is provided with a protrusion 11. The front end blast hole 12 for locking the wind wheel is provided on the lifter 11, the left and right sides of the rear part of the top plate 2 are provided with the first extension part 21 extending to the rear of the casing 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com