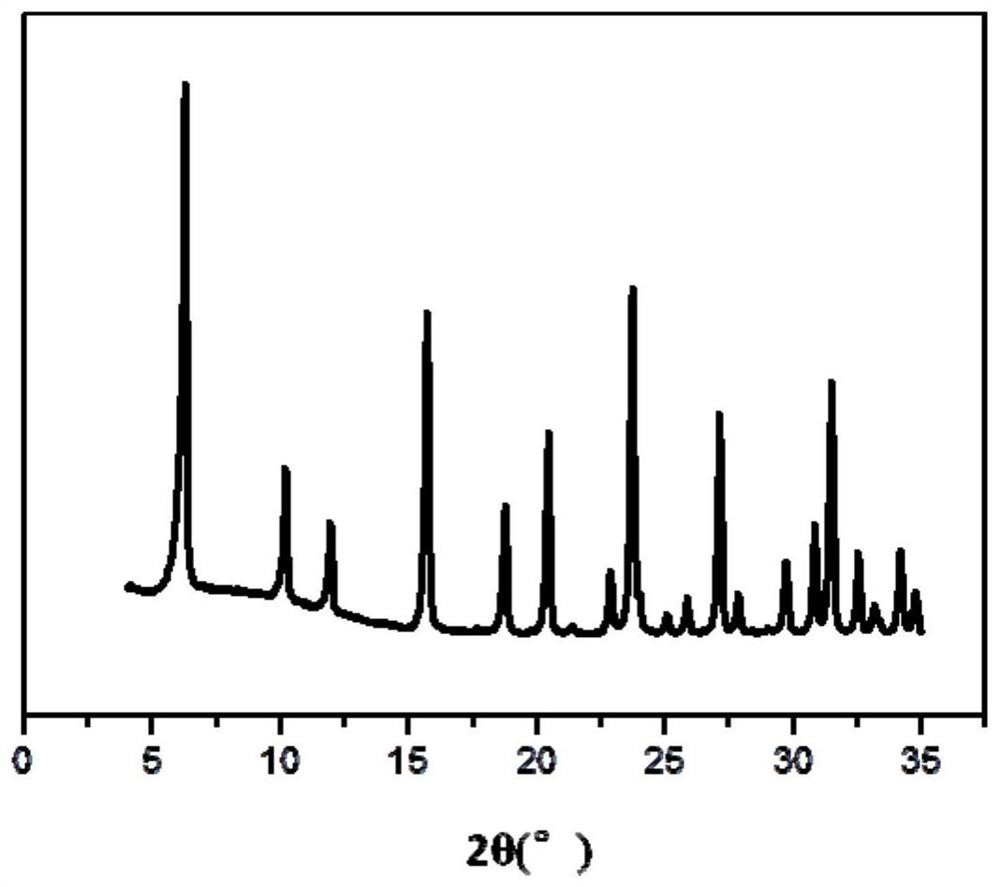

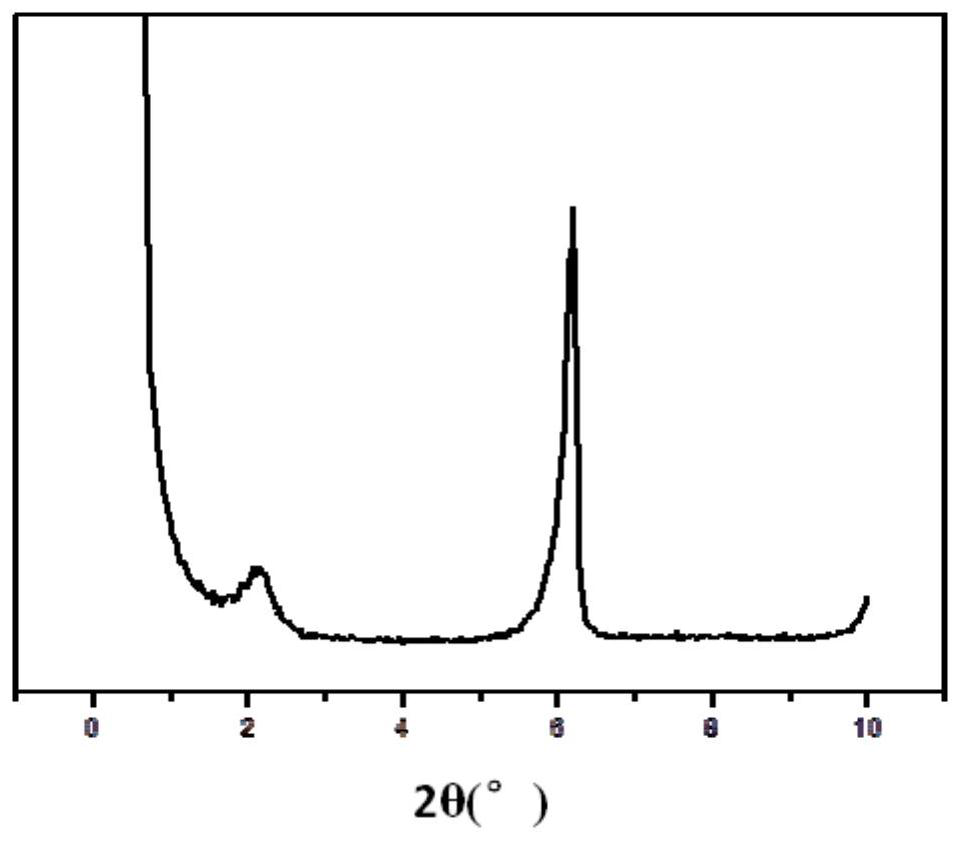

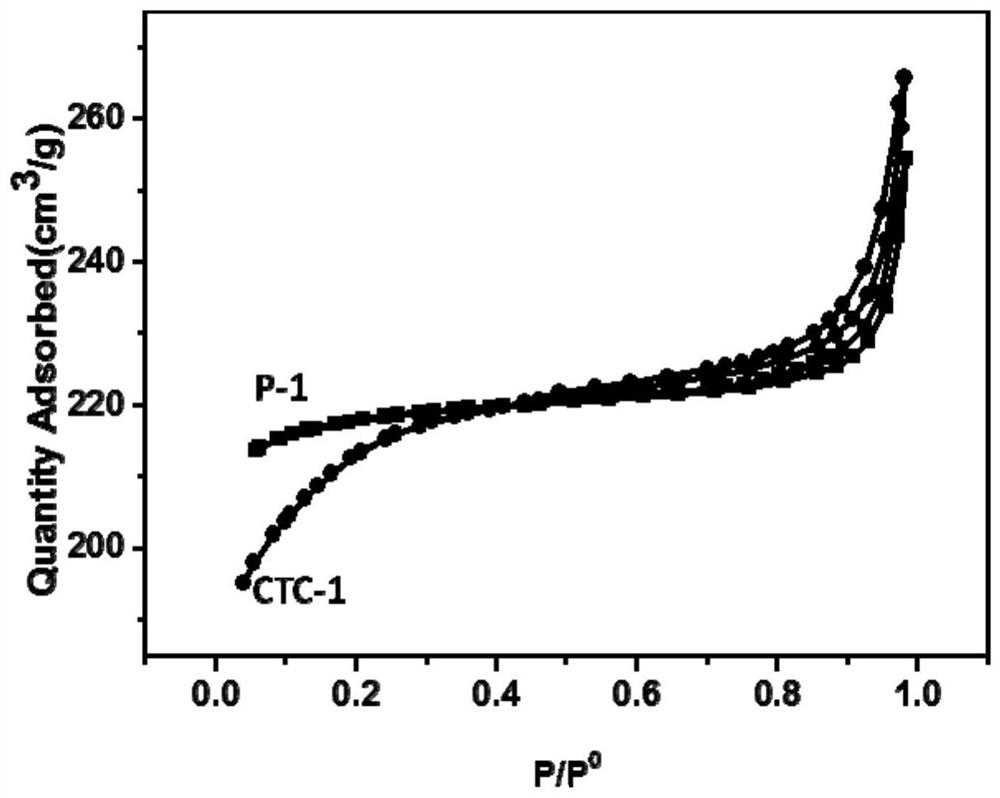

Modified y molecular sieve with regular meso-micropores and preparation method thereof

A molecular sieve and mesoporous technology, applied in the field of molecular sieves, can solve the problems of low activity, poor thermal and hydrothermal stability, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] 25.20g high-alkali sodium metaaluminate solution (provided by Sinopec Catalyst Changling Branch, Al 2 O 3 The content is 40.2g / L, Na 2 O content is 255g / L, specific gravity is 1.324) added to 32.78g water glass (provided by Sinopec Catalyst Changling Branch, SiO 2 The content is 260.6g / L, Na 2 The content of O is 81.6g / L, the specific gravity is 1.2655, and the modulus is 3.3), the molar composition is 15Na. 2 O:A1 2 O 3 :15SiO 2 The first mixture was dynamically stirred and aged at room temperature for 48 hours, and then allowed to stand for 5 hours at 60°C. Finally, 7.5g of deionized water was added under stirring to obtain a final molar composition of 15Na 2 O:A1 2 O 3 :15SiO 2 :320H 2 The second mixture of O is the directing agent.

[0073] Under the conditions of room temperature and high-speed stirring, follow the directing agent (prepared in the previous step), 84.13g water glass (same as above), 6.71g low-alkali sodium metaaluminate solution (provided by Sinopec Catal...

Embodiment 2

[0077] 25.20g high-alkali sodium metaaluminate solution (provided by Sinopec Catalyst Changling Branch, Al 2 O 3 The content is 40.2g / L, Na 2 O content is 255g / L, specific gravity is 1.324) added to 32.78g water glass (provided by Sinopec Catalyst Changling Branch, SiO 2 The content is 260.6g / L, Na 2 The content of O is 81.6g / L, the specific gravity is 1.2655, and the modulus is 3.3), the molar composition is 15Na. 2 O:A1 2 O 3 :15SiO 2 The first mixture was dynamically stirred and aged at 60°C for 5 hours, and then allowed to stand for 5 hours at 60°C. Finally, 7.5g of deionized water was added under stirring to obtain the final molar composition as 15Na 2 O:A1 2 O 3 :15SiO 2 :320H 2 The second mixture of O is the directing agent.

[0078] Under the conditions of room temperature and high-speed stirring, follow the directing agent (prepared in the previous step), 84.13g water glass (same as above), 6.71g low-alkali sodium metaaluminate solution (provided by Sinopec Catalyst Changl...

Embodiment 3

[0082] 82.27g of high-alkali sodium metaaluminate solution (provided by Sinopec Catalyst Changling Branch, Al 2 O 3 The content is 40.2g / L, Na 2 O content is 340g / L, specific gravity is 1.297) is added to 145.68g water glass (provided by Sinopec Catalyst Changling Branch, SiO 2 The content is 260.6g / L, Na 2 The O content is 81.6g / L, the specific gravity is 1.2655, and the modulus is 3.3), the molar composition obtained is 20Na 2 O:A1 2 O 3 :20SiO 2 The first mixture was dynamically stirred and aged at 30°C for 20 hours, and then allowed to stand for 15 hours at 40°C. Finally, 30g of deionized water was added under stirring to obtain a final molar composition of 20Na 2 O:A1 2 O 3 :20SiO 2 :380H 2 The second mixture of O is the directing agent.

[0083] Under the conditions of room temperature and high-speed stirring, follow the directing agent (prepared in the preceding steps), 54.63g water glass (same as above), 8.32 low-alkali sodium metaaluminate solution (provided by Sinopec Cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com