Additive sample bottle

A technology for sample vials and additives, applied in the direction of packaging objects, packaging, special packaging objects under special gas conditions, can solve the problems of invisible additives, unavoidable air contact of additives, waste of additives, etc., to avoid long-term contact , The detection is convenient and fast, and the effect of discoloration and degeneration is solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

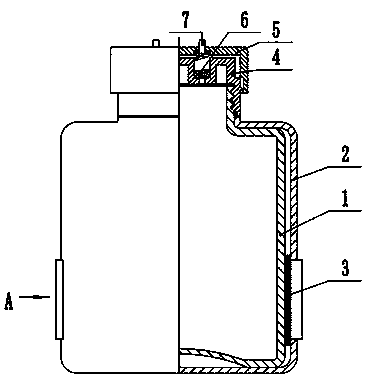

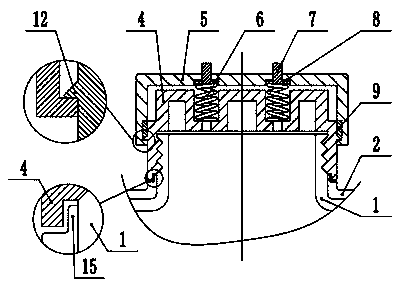

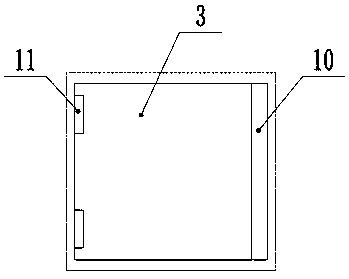

[0017] attached figure 1 It is a structural schematic diagram of the additive sample bottle of the present invention. The sample bottle includes an inner bottle 1 and an outer bottle 2, and an inner cap 4 and an outer cap 5 are installed at the mouth of the bottle. The outer bottle 1 is formed by overlapping two half-bottles, and the two half-bottles are close to the bottle shoulder 13 and the bottom 14 of the inner bottle, keeping a certain gap with the bottle body, and the gap can make the arc-shaped shading sheet 3 Move freely between inner and outer bottles. Each half bottle of the outer bottle is designed with an observation hole, as attached image 3 And attached Figure 4 As shown, the observation hole is completely blocked by the shading sheet 3, and the slat 10 and the arc-shaped positioning bar 11 that play a positioning role are designed on the shading sheet 3, and the slat 10 can be moved left and right to realize the movement of the shading sheet 3, thereby ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com