Production process for polymer cement waterproof mortar

A technology for waterproof mortar and production process, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc. It can improve the batching efficiency, good dispersibility and uniform particles by solving the problems of different distribution and uneven mixing of the master powder of auxiliary agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

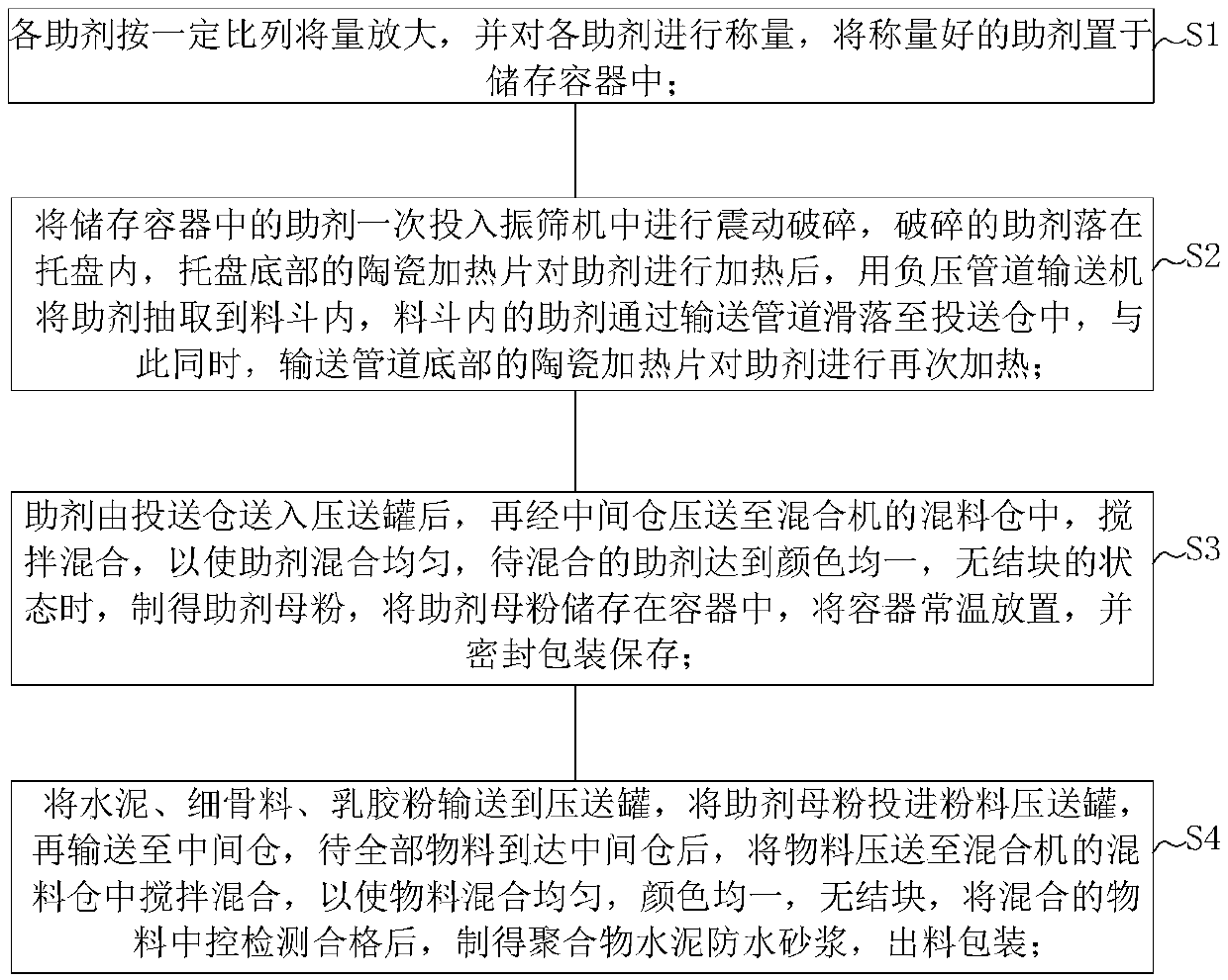

[0029] like figure 1 Shown, a kind of production technology of polymer cement waterproof mortar comprises the following production steps:

[0030] S1 The various additives of polymer cement waterproof mortar are enlarged according to a certain ratio, and the various powder additives are weighed in turn, and the weighed additives are placed in the storage container;

[0031] S2 Put the additives in the storage container into the vibrating screen machine for vibration and crushing. The broken additives fall into the tray. After the ceramic heating plate at the bottom of the tray heats the additives, the additives are extracted by a negative pressure pipeline conveyor. Into the hopper, the additive in the hopper slides down to the delivery bin through the conveying pipeline, and at the same time, the ceramic heating plate at the bottom of the conveying pipeline reheats the additive;

[0032] After the S3 additive is sent into the pressure delivery tank from the delivery bin, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com