Punching machine die for hydraulic pipe bending machine bending pipes efficiently

A pipe bending machine and pipe bending technology, which is applied in the field of punch press moulds for hydraulic pipe benders, can solve problems such as the inability to meet the needs of the peak season of fitness equipment production, the inability of punch press moulds to quickly locate and punch, and the reduction of pipe bending efficiency of hydraulic pipe benders. , to achieve the effect of simple structure, reasonable design and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

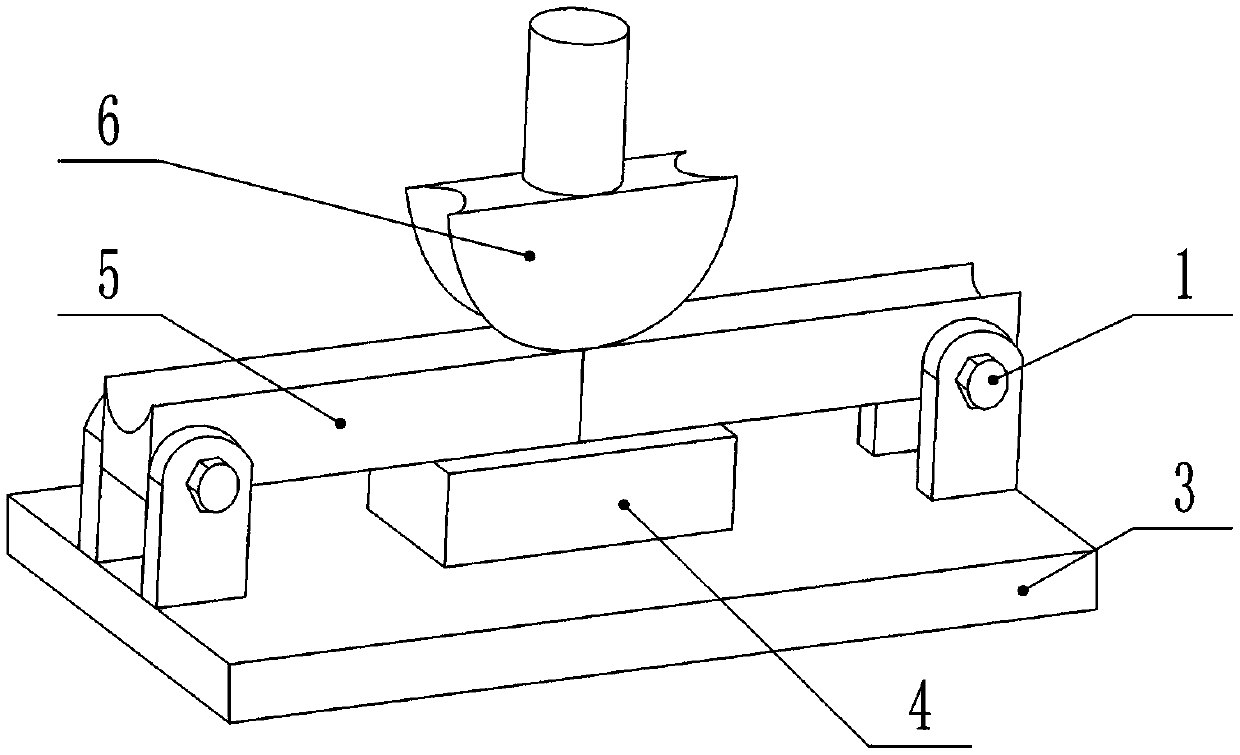

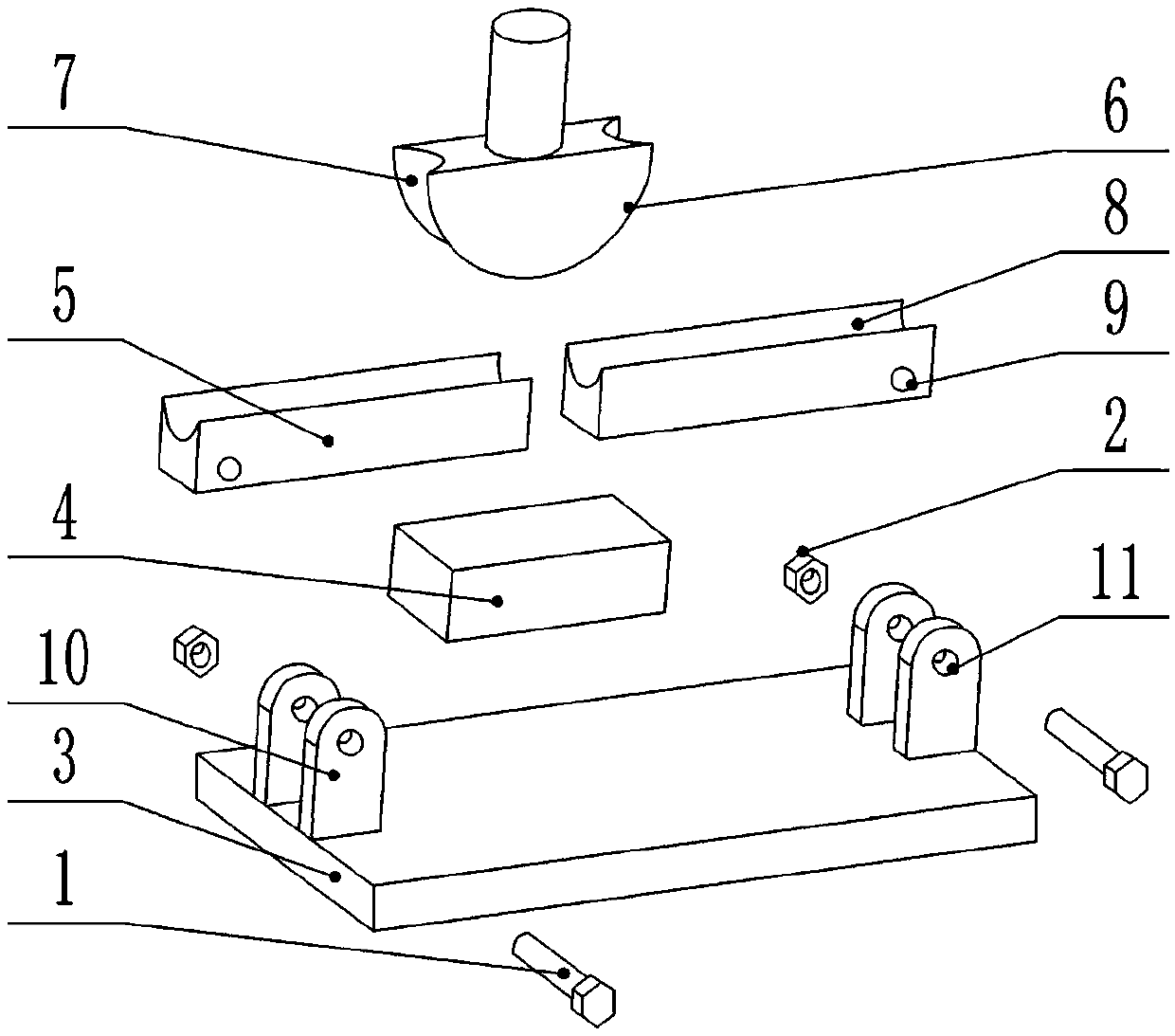

[0014] As shown in the figure, a high-efficiency hydraulic pipe bender punch die for pipe bending includes a lower die 5 and an upper die 6, and is characterized in that the lower die 5 is located below the upper die 6, and the upper die The cross section of 6 is set in the shape of a half-bent pipe wheel, and the curved surface of the upper die 6 is provided with a pipe bend groove 7, and the center of the horizontal plane of the upper die 6 is vertically fixed with a connecting rod, and the lower die 5 includes the elbow lower die clamping block one and the elbow lower die clamping block two, the elbow lower die clamping block one and the elbow lower die clamping block two are arranged flush from left to right, the elbow lower die clamping block two The upper part of the mold clamping block 1 and the elbow lower mold clamping block 2 are coaxially provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com