Automatic ball stringing machine

An automatic threading and meatball technology, which is applied in the direction of putting meat skewers on meat skewers, slaughtering, meat processing equipment, etc., can solve the problem of low efficiency of threading meatballs, and achieve the effect of improving efficiency and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

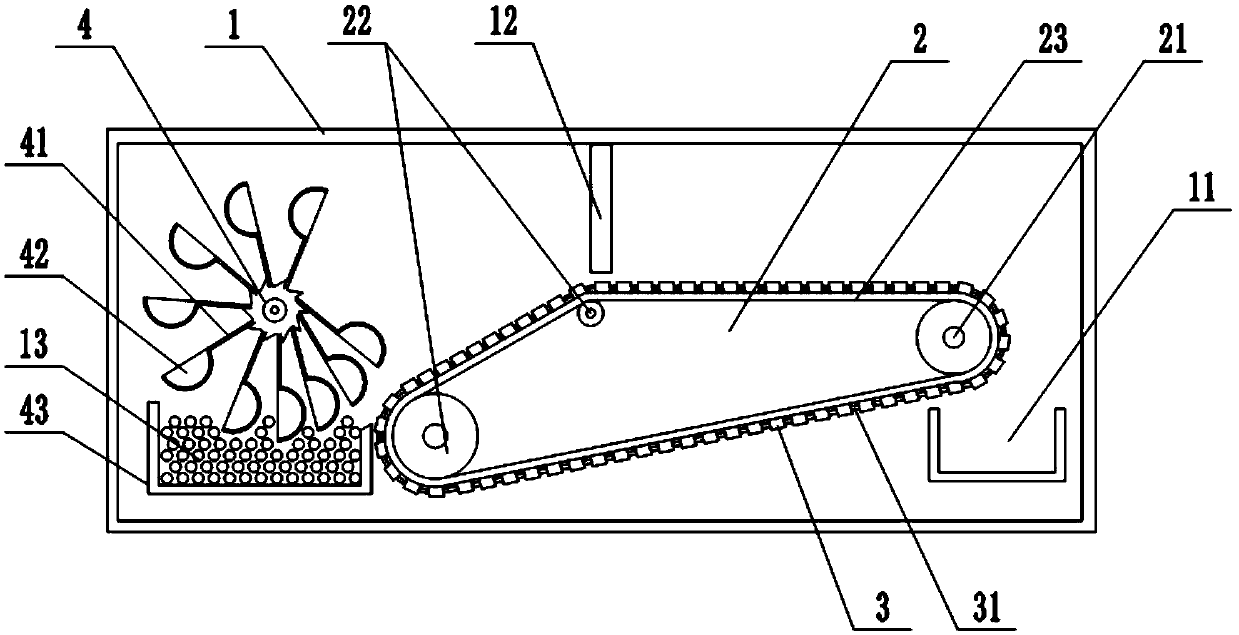

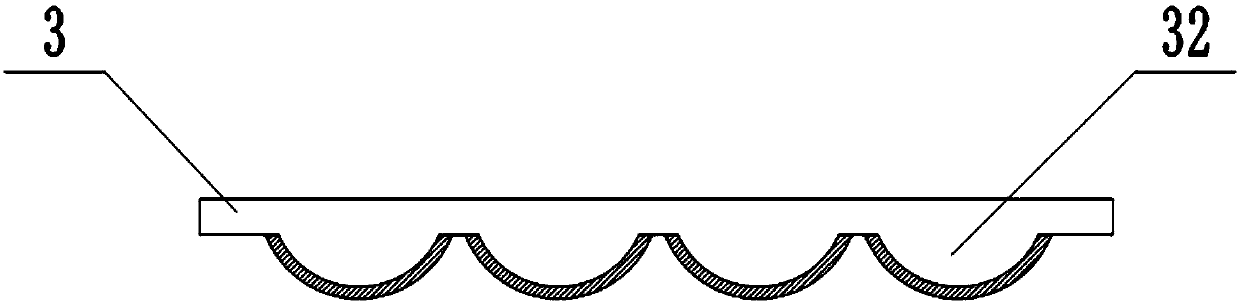

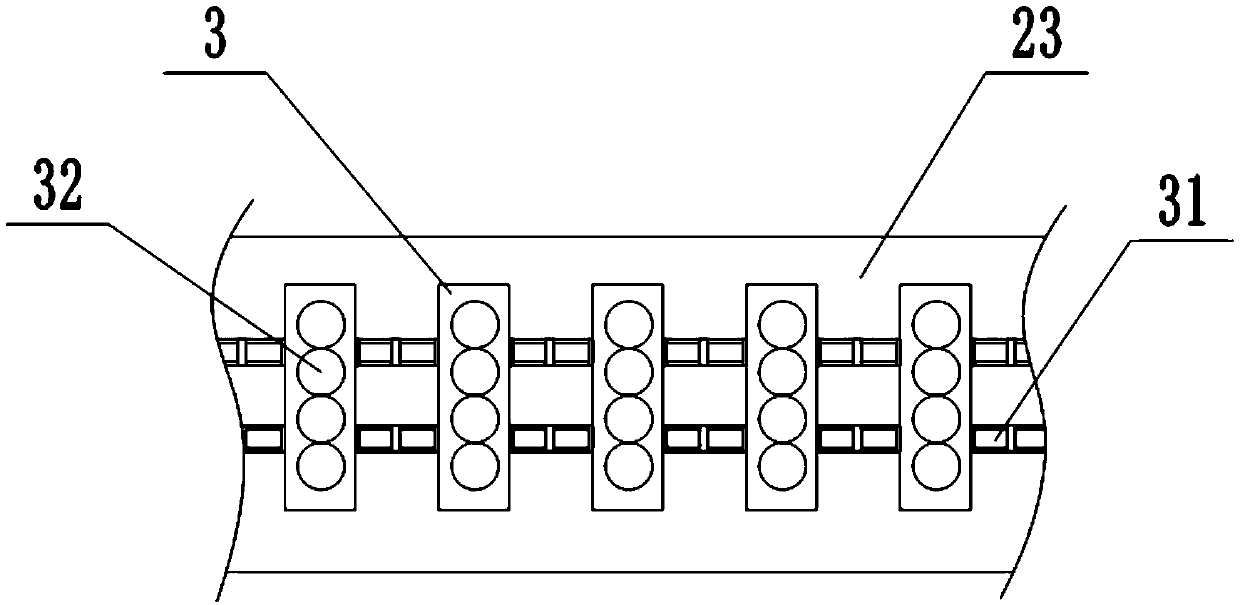

[0019] The reference signs in the accompanying drawings of the description include: box body 1, collection box 11, material blocking plate 12, ball 13, conveyor belt 2, driving wheel 21, driven wheel 22, belt 23, material storage mold 3, chain link 31, holding Groove 32, ratchet disc 4, articulated rod 41, material guide hopper 42, material storage box 43, bamboo stick box 5, housing 51, rotating roller 52, opening 53, pick-up groove 54, baffle plate 6, pressure sensor 61, place Platform 7, bamboo stick 71, first support 8, first push rod 81, fixed block 82, spring 83, pole 84, second support 9, second push rod 91, cam 92, fourth motor 93.

[0020] The embodiment is basically as attached Figures 1 to 5 Shown: an automatic stringing machine for meatballs, including a box body 1, a feeding device, a conveyor belt 2 and a collection box 11. A DSP controller is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com