Single-pair supersonic flow direction vortex generation device

A generation device, supersonic technology, applied in the direction of internal combustion engine testing, etc., to achieve uniform flow parameters, easy flow field display, and avoid pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

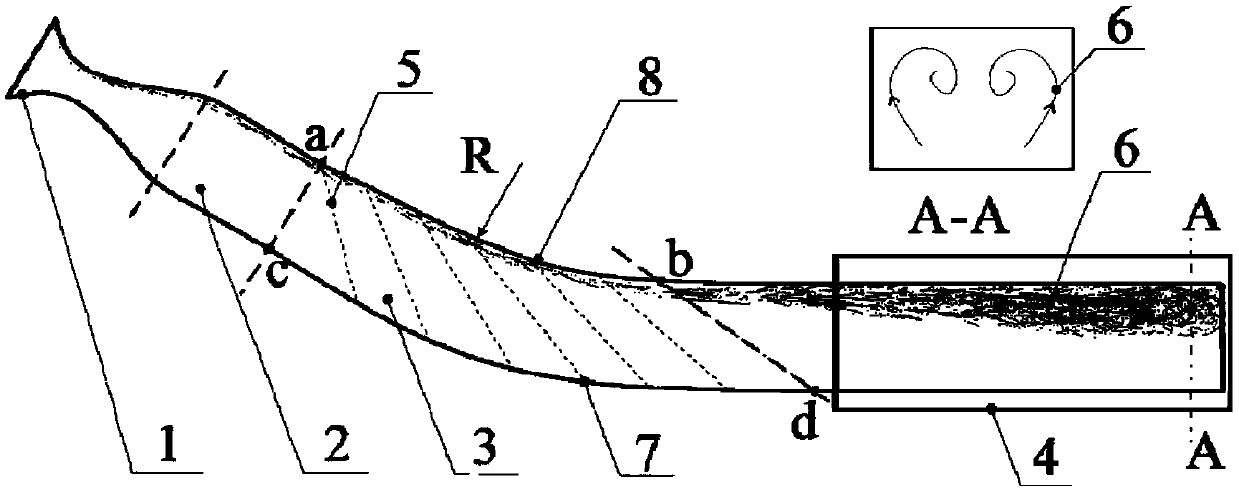

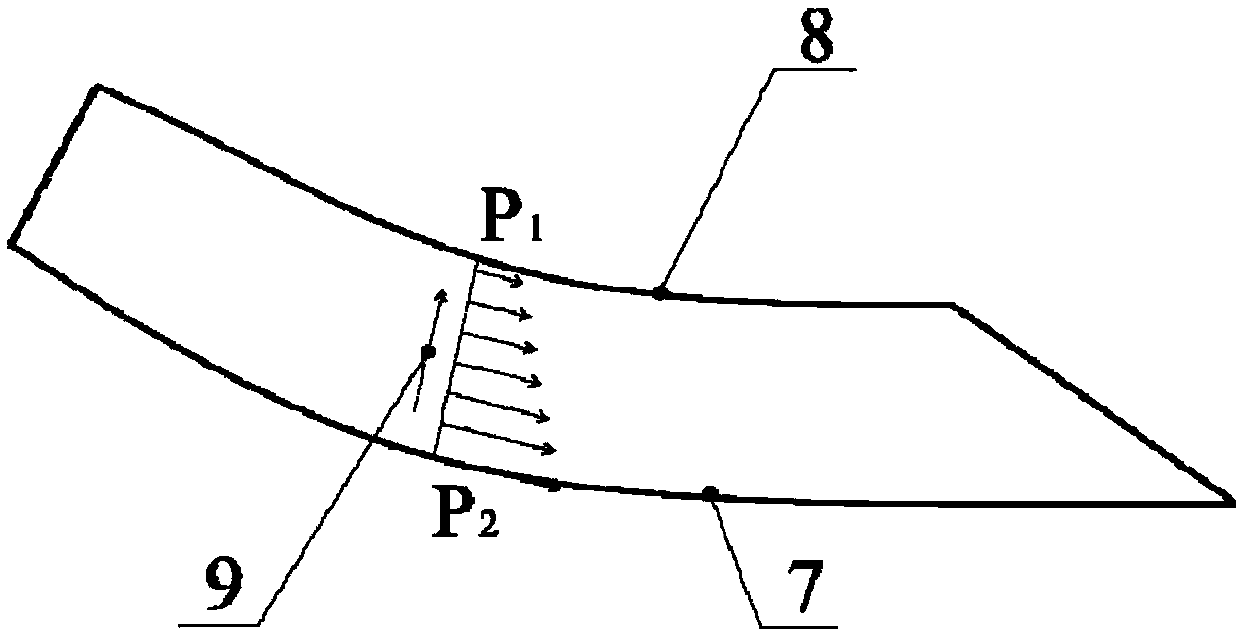

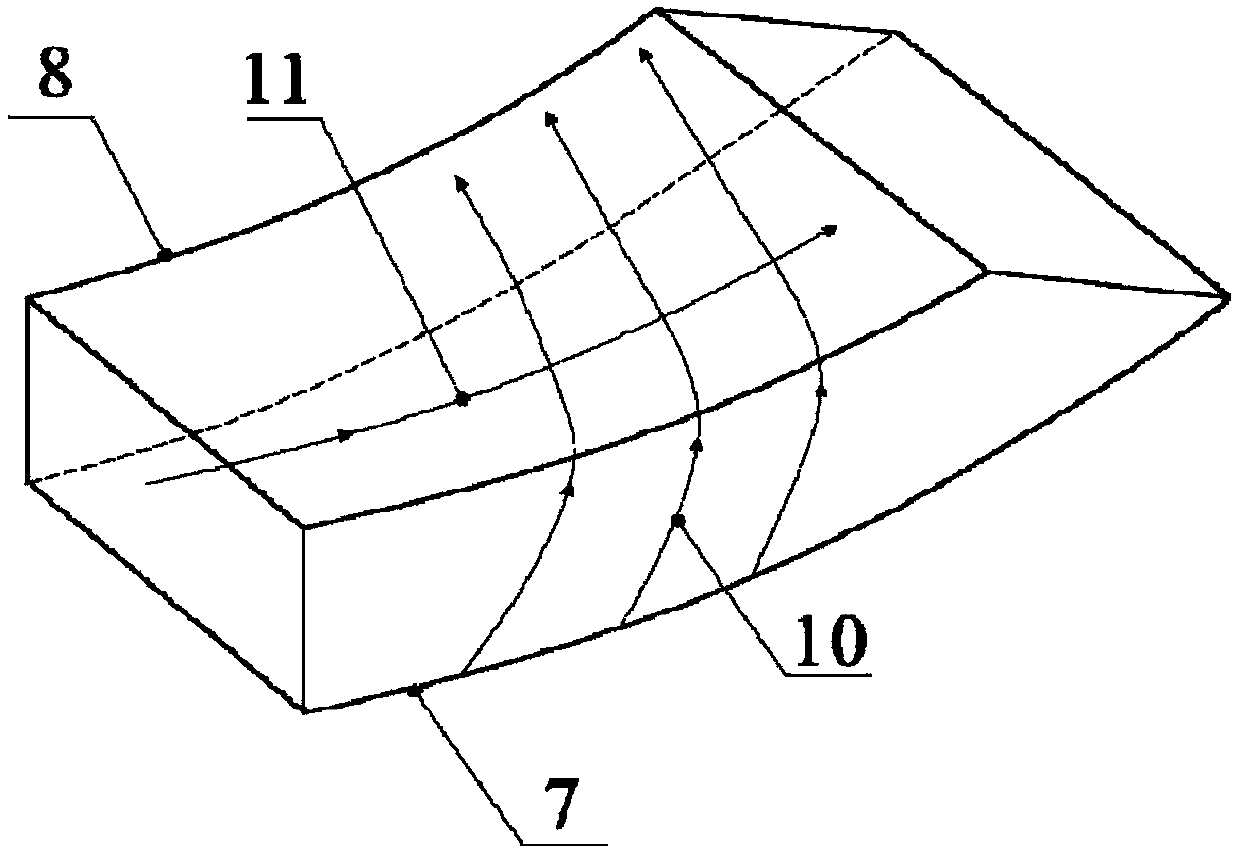

[0015] see figure 1 As shown, the present invention provides a single-pair supersonic flow direction vortex generating device without background wave system, including a Laval nozzle 1 , a transition section 2 , a vortex generating section 3 and a test window 4 . The vortex generating section 3 is a curved pipe, the upper wall profile 8 of the vortex generating section 3 is a circular arc with a radius R, and the lower wall 7 of the vortex generating section 3 is a curved profile. The local tangential direction of the starting point a of the upper wall surface is consistent with the tangential direction of the starting point of the lower wall surface 7, and the tangential direction of the ending point b of the upper wall surface is consistent with the tangential direction of the ending point of the lower wall surface 7. Inside the vortex generating section 3, there are a series of continuous right-going expansion waves 5 formed from the upper wall of the pipeline. The first no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com