A concrete conveying device

A technology for conveying devices and transport pipes, which is applied in construction, infrastructure engineering, etc., and can solve problems such as discontinuous pouring, difficulty in controlling excess irrigation, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

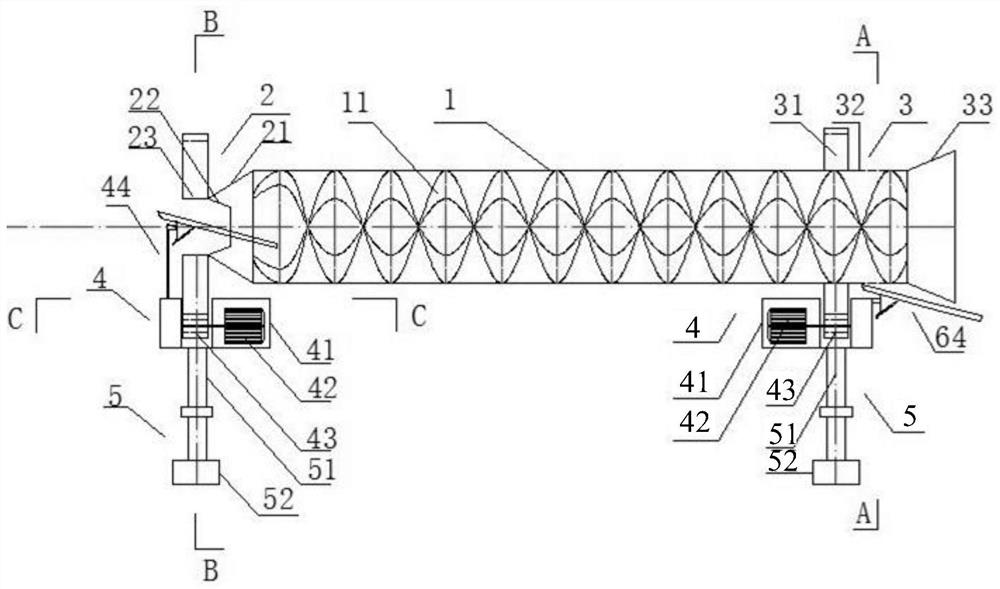

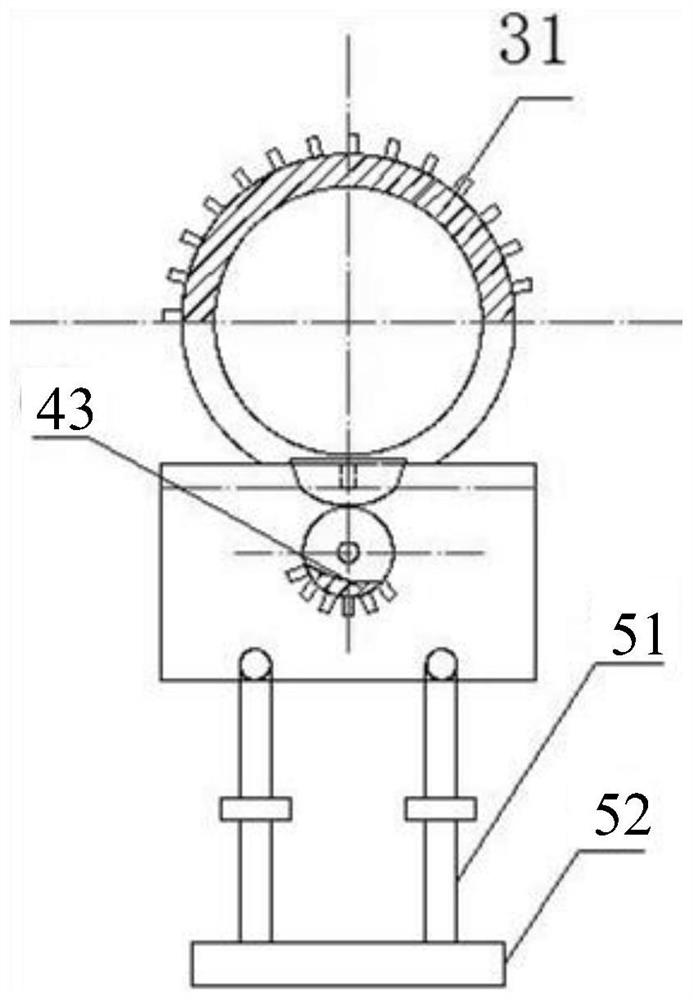

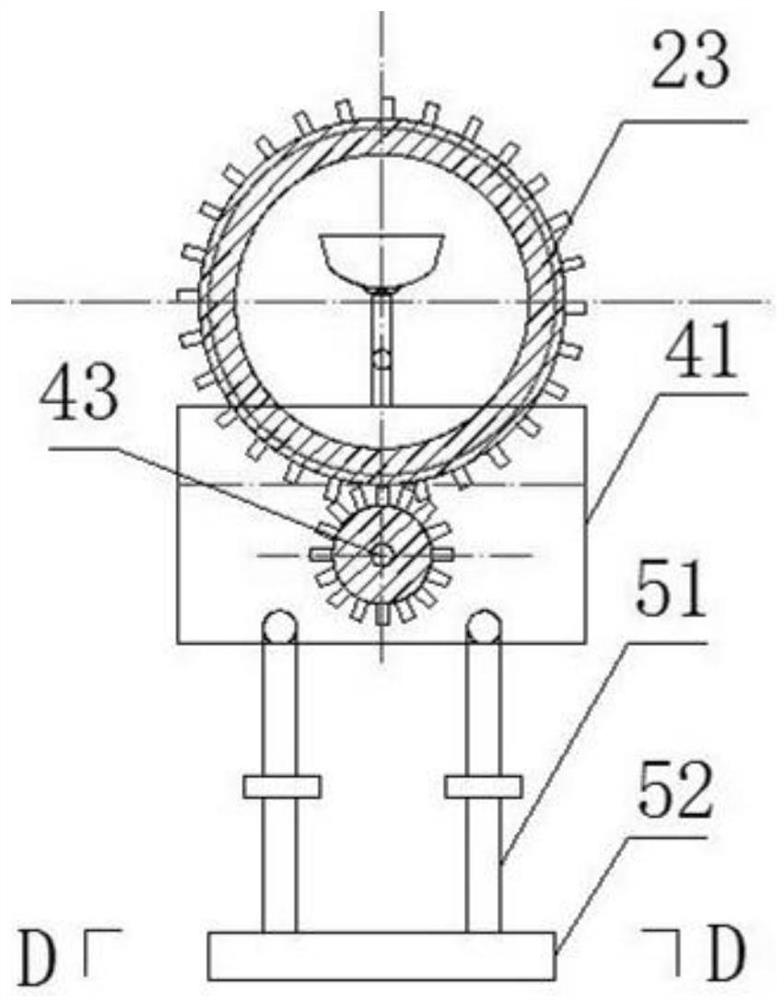

[0043] based on the following Figure 1 to Figure 8 , specifically explain the preferred embodiment of the present invention.

[0044] The invention provides a concrete conveying device, comprising:

[0045] The transportation pipe body is provided with a plurality of helical blades, and the helical blades can keep the concrete in a stirring state and not flow out of the transportation pipe body when the transportation pipe body is rotating forward, and the concrete will flow out of the transportation pipe body when the transportation pipe body is reversed;

[0046] At least two support control components, which are respectively arranged at the feeding end and the discharging end of the transportation pipe body, control the forward rotation or reverse rotation of the transportation pipe body, and adjust the inclination angle of the transportation pipe body, so as to realize the conveying and mixing of concrete .

[0047] Such as figure 1 As shown, the transport pipe body in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com