Development device for modified asphalt

A technology of modified asphalt and asphalt, which is applied in the field of modified asphalt development equipment, can solve the problems of coking in the development tank, achieve the effects of constant development temperature, stable structure, and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

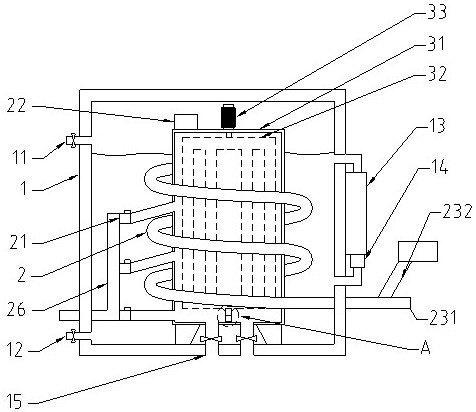

[0037]Such asFigure 1~6Shown is a development device for modified asphalt, which includes an outer casing 1, a cooling unit, and a development tank from the outside to the inside. The outer casing 1 is a sealed cylinder, and the outer casing 1 is double-layered. Vacuuming between the two layers can reduce heat loss. The outer shell 1 is equipped with cooling oil. The side of the outer shell 1 has an oil inlet 11 and an oil outlet 12. The cooling oil in the outer shell 1 can be replaced. The temperature at which the bitumen enters the outer shell 1 is higher than the temperature required for development, so the cooling oil is used to reduce the temperature of the bitumen to the development temperature. However, this embodiment does not use the outer wall of the outer shell 1 for heat dissipation. This is because the actual production site equipment The arrangement is relatively close, especially for large-scale production. Once the outer shell 1 with a large floor area radiates heat,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com