A combined opening device for a large tonnage skip gate and a shroud

A technology of opening device and shroud, which is applied in packaging, large containers, transportation and packaging, etc. It can solve the problems of inaccurate mechanical limit of the gate, heavy maintenance workload of the gate, asynchronous opening of the gate, etc. Strict or unable to reset the phenomenon, saving installation and debugging time, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

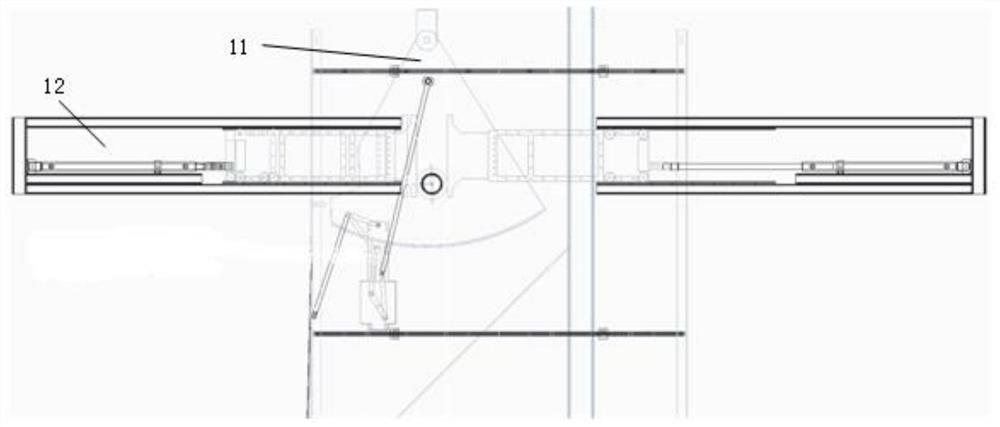

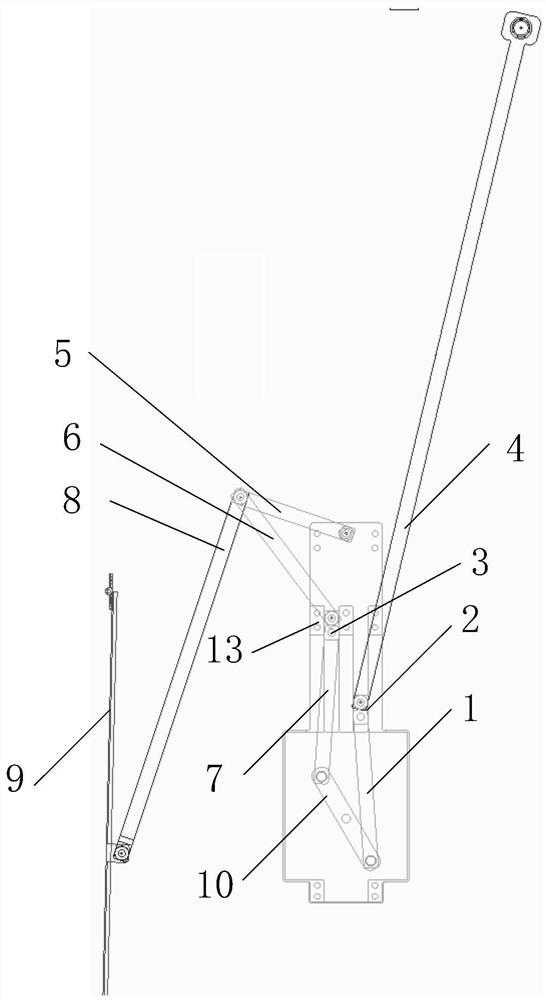

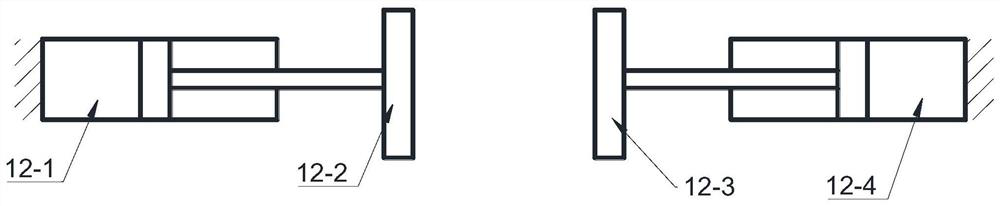

[0023] Such as figure 1 , figure 2 , Figure 7 to Figure 10 As shown, a large-tonnage skip gate and deflector joint opening device includes a skip, a skip gate 11 installed on the front and rear sides of the skip, and a deflector gate 9 installed at the lower end of the left side of the skip. The bucket gate 11 is a fan-shaped gate, and the upper end of the skip gate 11 is hinged on the upper end of the skip opening, and is driven to open and close by the opening device; it is characterized in that the opening device includes hydraulic pressure valves symmetrically arranged on the front and rear sides of the skip. The cylinder driving device 12 and the multi-link mechanism, the hydraulic driving device 12 is connected with the skip gate 11 to drive the gate to open and close; the multi-link mechanism includes connecting rod one 1, connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com