A kind of manufacturing device and manufacturing method of engineering plastic drainage board

A technology of plastic drainage board and engineering plastics, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of inaccuracy, difficulty in fixing, and no addition of induction copper wires, etc., to achieve accurate induction, high fusion strength, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The present invention will be further described in detail below in conjunction with the drawings.

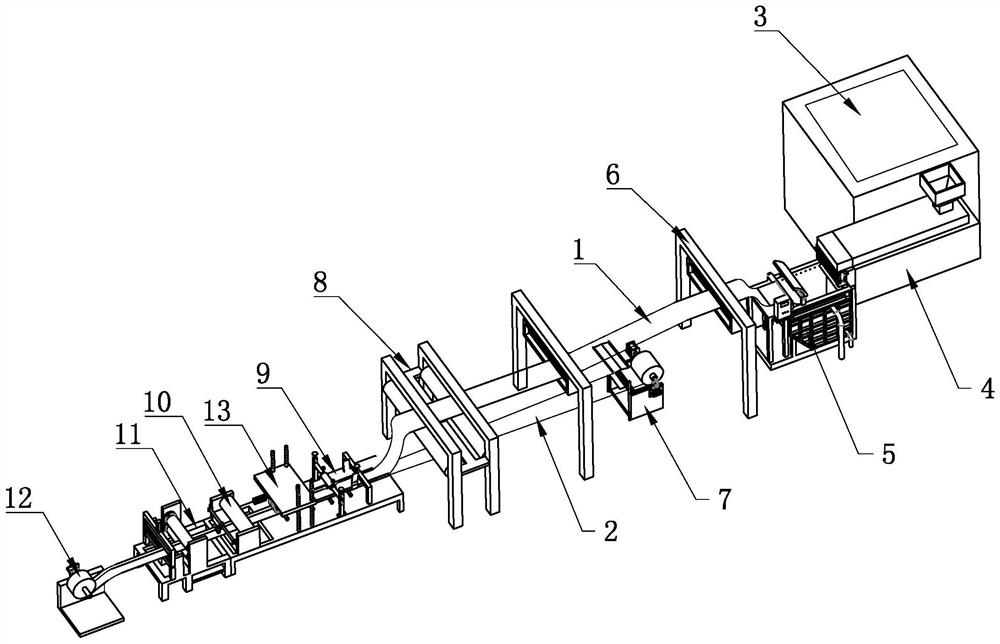

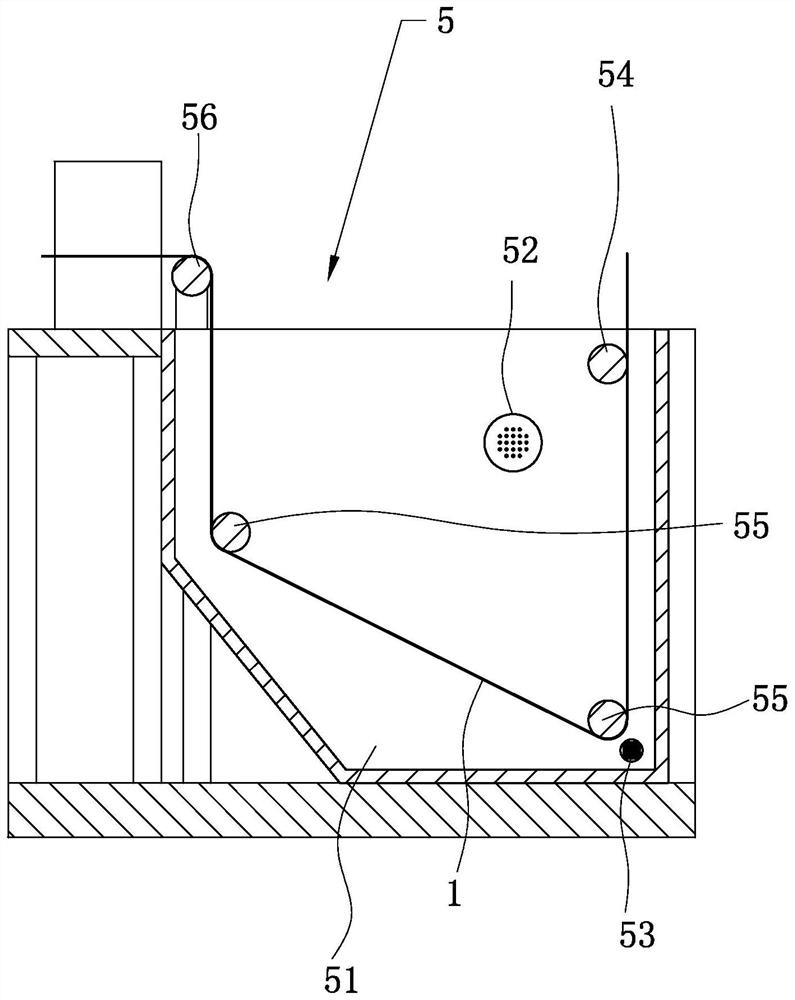

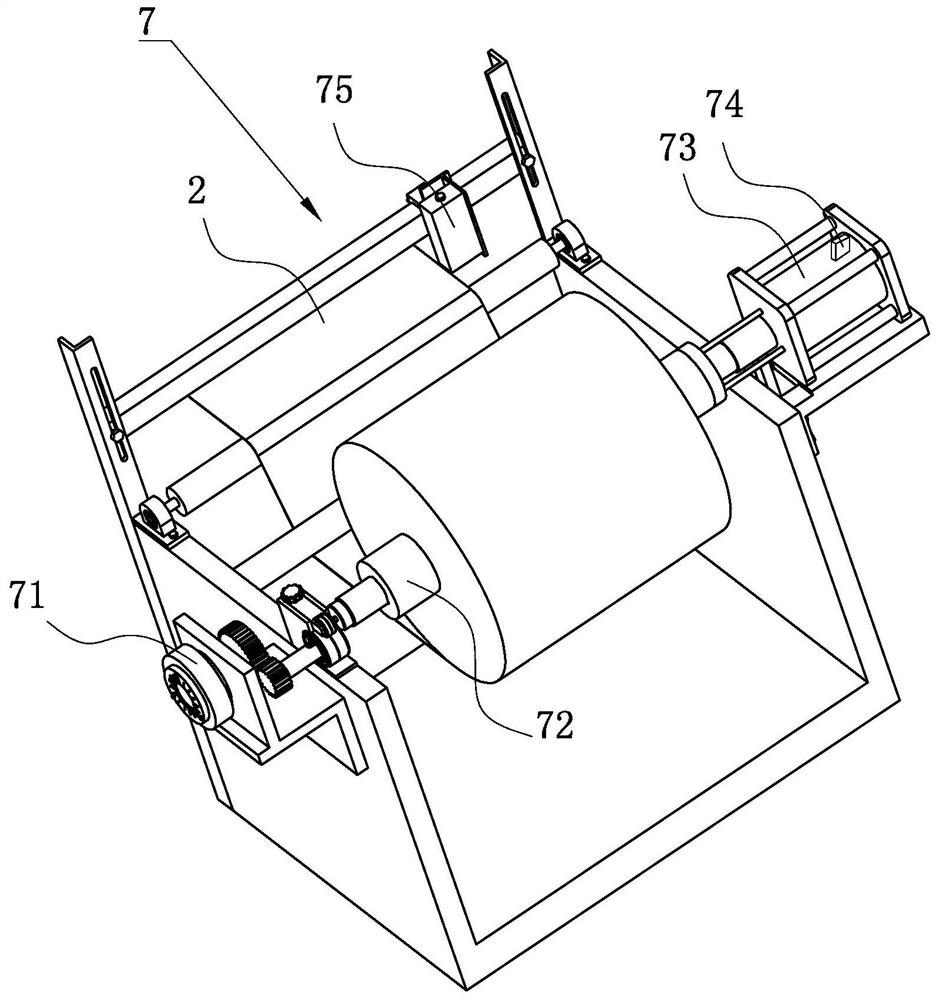

[0052]Referencefigure 1 , Is an engineering plastic drainage board manufacturing device disclosed in the present invention, which includes a feeding device 3, a pressing device 10 and a winding device 12, and the discharge port of the feeding device 3 is connected to the feeding port of the extrusion device 4 , The plastic drainage plate 1 extruded in the extrusion device 4 passes through the cooling device 5, the drying device 6, the film correction device 7, the copper wire filling device 8, the adjustable coating device 9, the pressing device 10, and the automatic cutting device. 11 and winding device 12, in this embodiment, the drying device 6, the film correction device 7, the copper wire filling device 8, the adjustable covering device 9, the pressing device 10, and the automatic cutting device 11 are all equipped with rollers , The drum is connected with the driving device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com