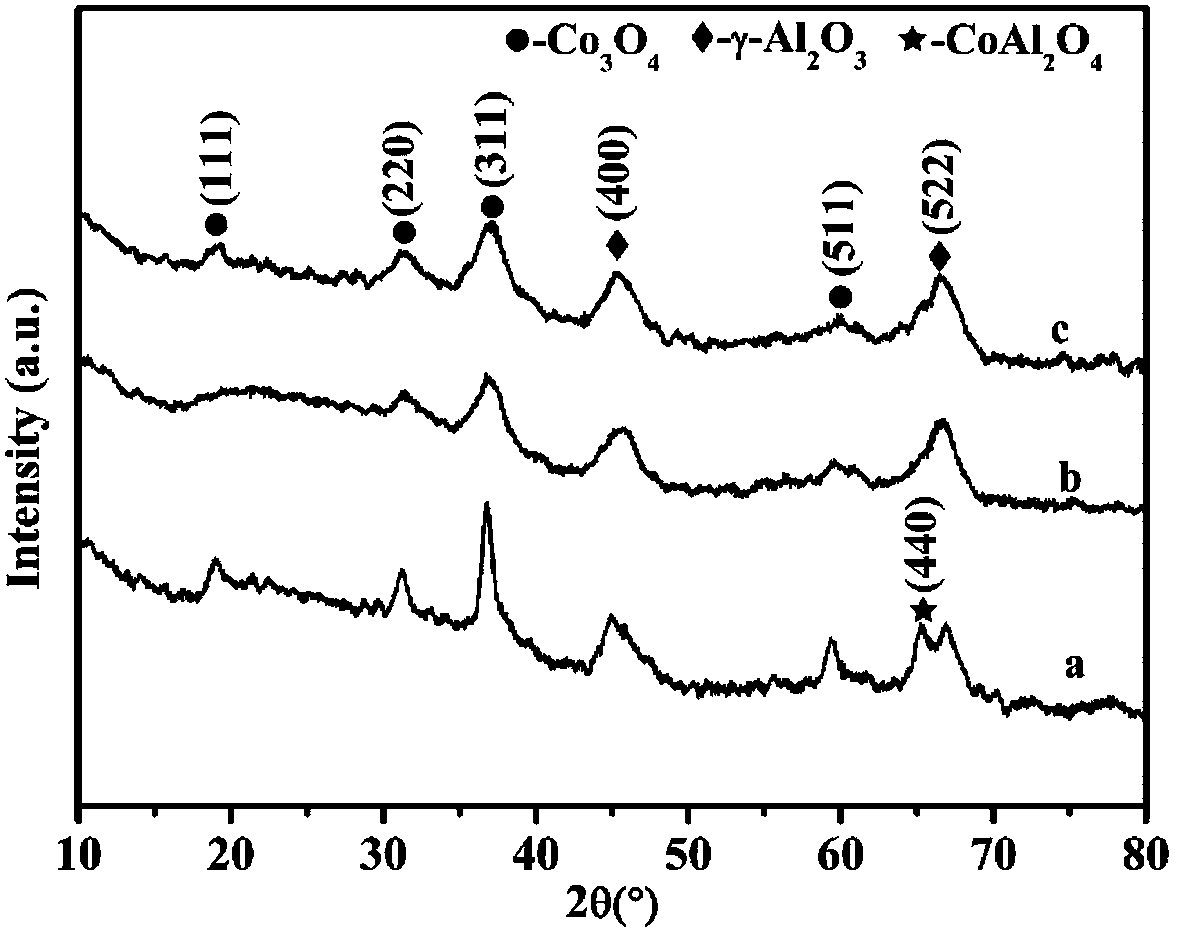

Preparation method of small-grain-size cobalt-based aluminum oxide catalyst

A technology based on alumina and catalysts, applied in catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to facilitate material diffusion and heat transfer, simple operation, and pore channels orderly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

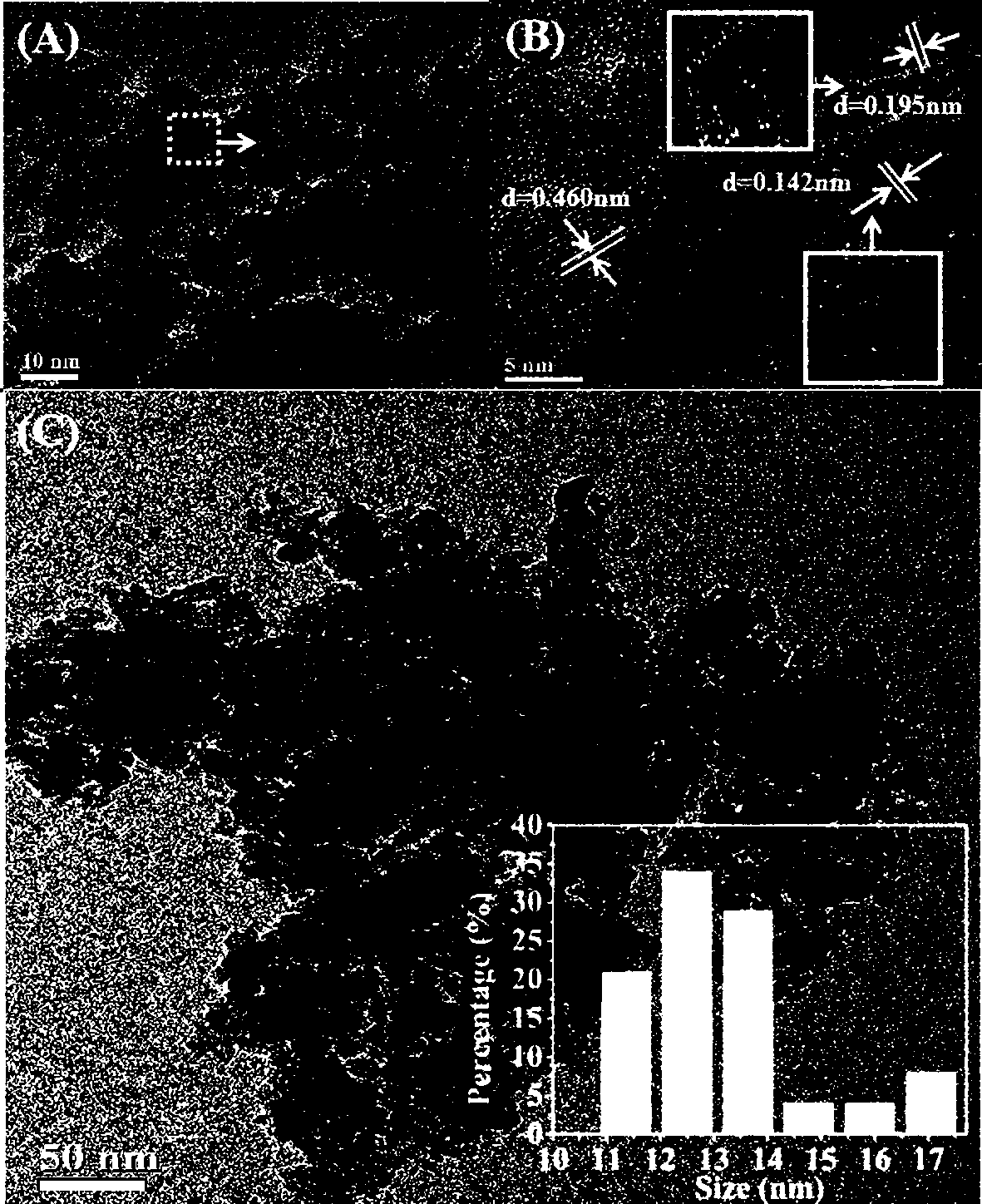

Embodiment 1

[0036] 1) Dissolve 1g of P123 into a mixed solution consisting of 20ml of absolute ethanol, 0.8ml of hydrochloric acid (37wt%) and 0.1ml of interface protective agent acetic acid;

[0037] 2) Dissolve 2.04g of aluminum isopropoxide into the mixed solution of step 1) and stir for 5 hours until the mixture is uniform to form a sol, and the final pH of the sol is = 2.0;

[0038] 3) Aging the sol obtained in step 2) at 30°C for 10 hours and drying at 100°C to obtain a xerogel;

[0039] 4) Calcining the xerogel obtained in step 3) from room temperature to 500°C at a heating rate of 1°C / min for 4 hours, and then at a heating rate of 10°C / min to 800°C for 1 hour to prepare ordered mesoporous alumina carrier;

[0040] 5) impregnating the alumina carrier obtained in the above steps into a mixed solution consisting of deionized water, diethylene glycol and cobalt acetate, wherein the molar ratio of diethylene glycol, alumina and cobalt acetate tetrahydrate is 1:5:2, Then impregnated a...

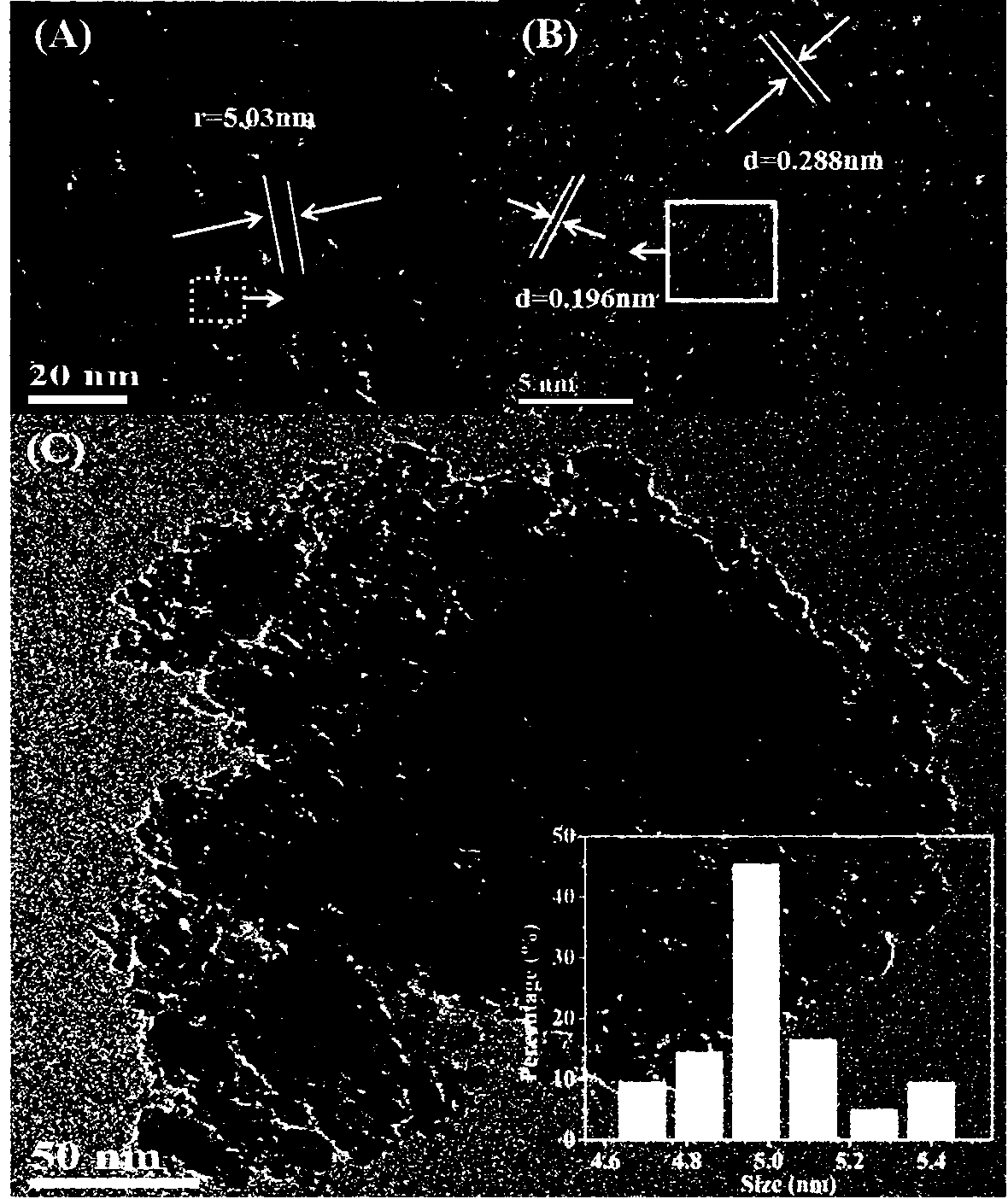

Embodiment 2

[0042] 1) Dissolve 1g of P123 into a mixed solution consisting of 20ml of absolute ethanol, 0.8ml of hydrochloric acid (37wt%) and 0.1ml of interface protective agent acetic acid;

[0043] 2) Dissolve 2.04g of aluminum isopropoxide into the mixed solution of step 1) and stir for 5 hours until the mixture is uniform to form a sol, and the final pH of the sol is = 2.0;

[0044] 3) Aging the sol obtained in step 2) at 30°C for 10 hours and drying at 100°C to obtain a xerogel;

[0045] 4) Calcining the xerogel obtained in step 3) from room temperature to 500°C at a heating rate of 1°C / min for 4 hours, and then at a heating rate of 10°C / min to 800°C for 1 hour to obtain an alumina carrier;

[0046]5) Immerse the alumina carrier obtained in step 4) into a mixed solution consisting of deionized water, diethylene glycol and cobalt acetate, wherein the molar ratio of diethylene glycol, alumina and cobalt acetate tetrahydrate is 3:5:2 , then impregnated at room temperature for 5h, drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com