Energy-saving non-fusel oil dividing wall column-coupled multi-effect methanol rectification device and method

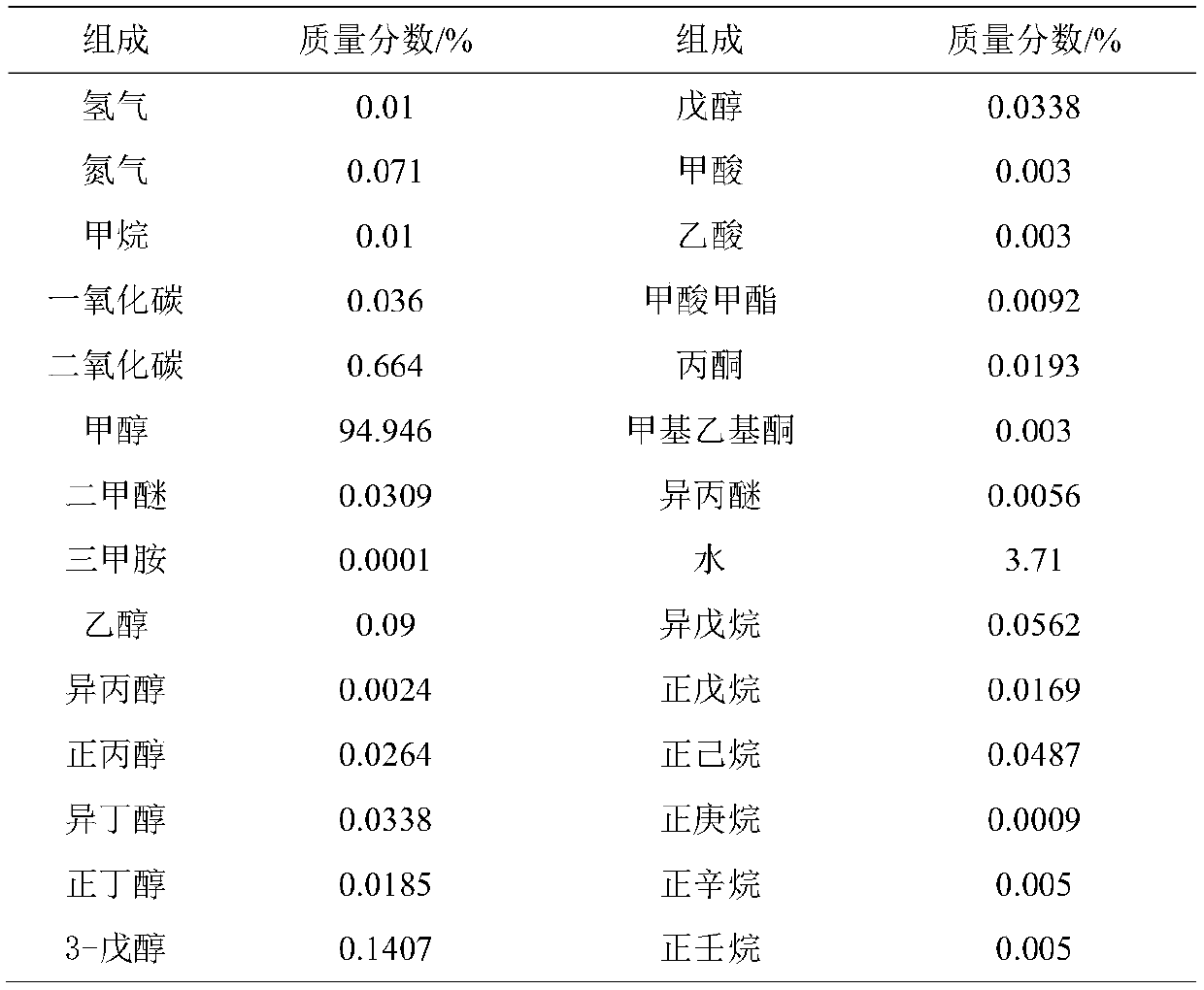

A multi-effect rectification and fusel oil technology, which is applied in the field of fusel oil-free dividing wall column coupling methanol multi-effect rectification energy-saving device, can solve the problem of insufficient heat utilization in the process, high energy consumption of the overhead condenser of the atmospheric tower, etc. problems, to achieve the effect of improving raw material utilization, saving steam energy consumption, and increasing process economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

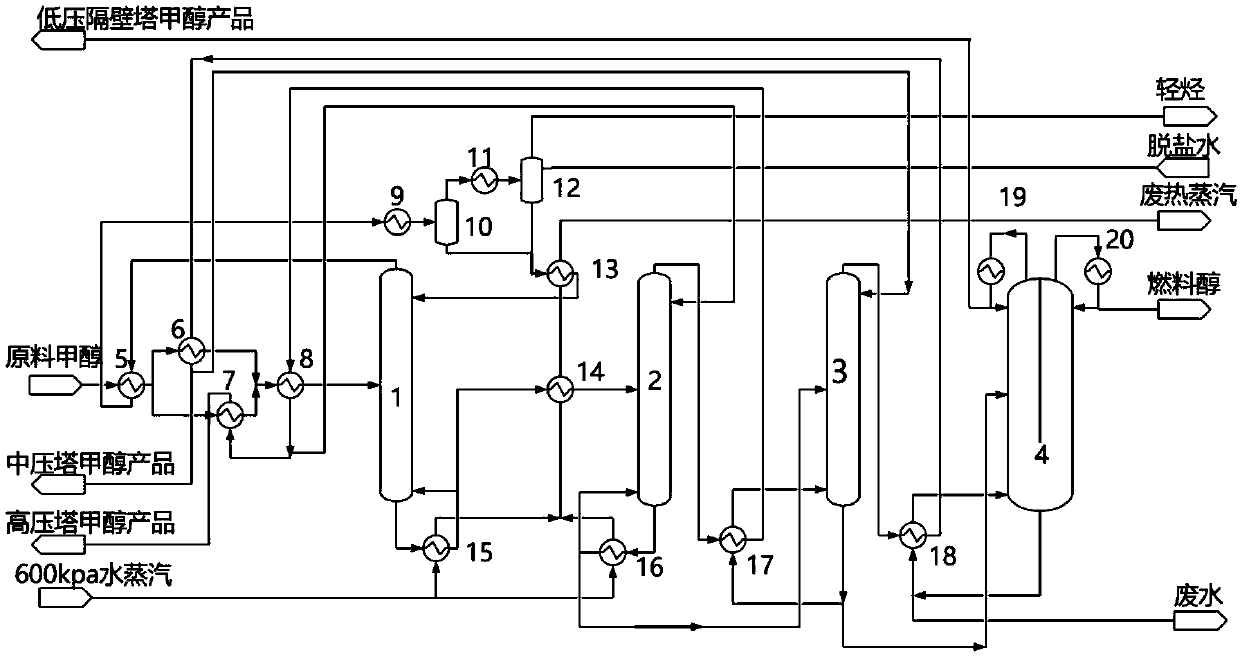

[0027] Combine below figure 1 The apparatus and method of the present invention are further described.

[0028] The device includes a light removal tower, a high pressure tower, a medium pressure tower, and a low-pressure fusel oil-free dividing wall tower; the bottom of the light removal tower is connected to the middle and lower part of the high pressure tower through a pipeline and a steam primary heat exchanger; the bottom of the high pressure tower is connected through a pipe The road is connected with the middle and lower part of the medium pressure tower. The bottom of the medium-pressure column is connected with the middle and lower part of the low-pressure fusel oil-free dividing wall column through a pipeline.

[0029] The low-pressure fusel oil-free dividing wall column adopts a built-in partition, which is located at the top of the column and is closely connected with the top of the column; the stream enters the middle of the low-pressure fusel oil-free dividing w...

Embodiment 2

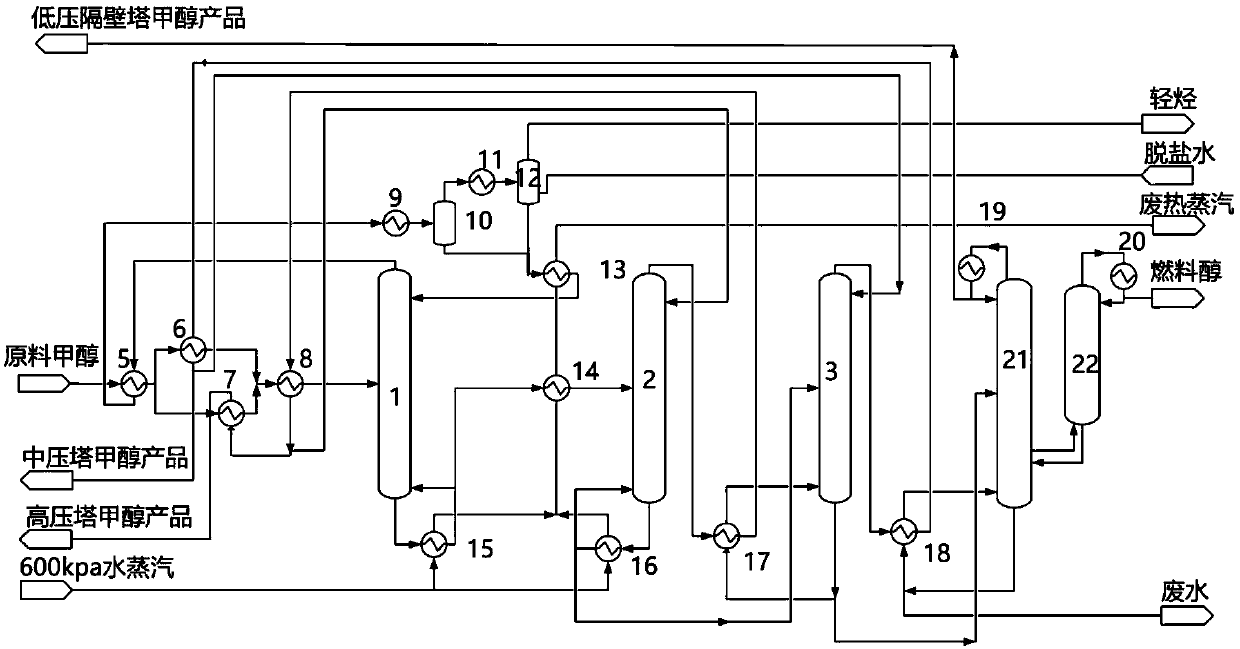

[0040] Combine below figure 2 The apparatus and method of the present invention are further described.

[0041] The device includes a light removal tower, a high pressure tower, a medium pressure tower, and a low-pressure fusel oil-free dividing wall tower; the bottom of the light removal tower is connected to the middle and lower part of the high pressure tower through a pipeline and a steam primary heat exchanger; the bottom of the high pressure tower is connected through a pipe The road is connected with the middle and lower part of the medium pressure tower. The bottom of the medium-pressure column is connected with the middle and lower part of the low-pressure fusel oil-free dividing wall column through a pipeline.

[0042] External wall-mounted low-pressure fusel oil-free bulkhead tower, including the main tower and externally suspended auxiliary tower; the flow enters the middle and lower part of the low-pressure main tower, the methanol product is extracted from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com