Method and device for changing the dynamic behaviour of a back rest of a weaving machine

A backrest beam, loom technology, applied to looms, textiles, papermaking, textiles, etc., can solve unreasonable and inappropriate problems, and achieve the effect of large resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

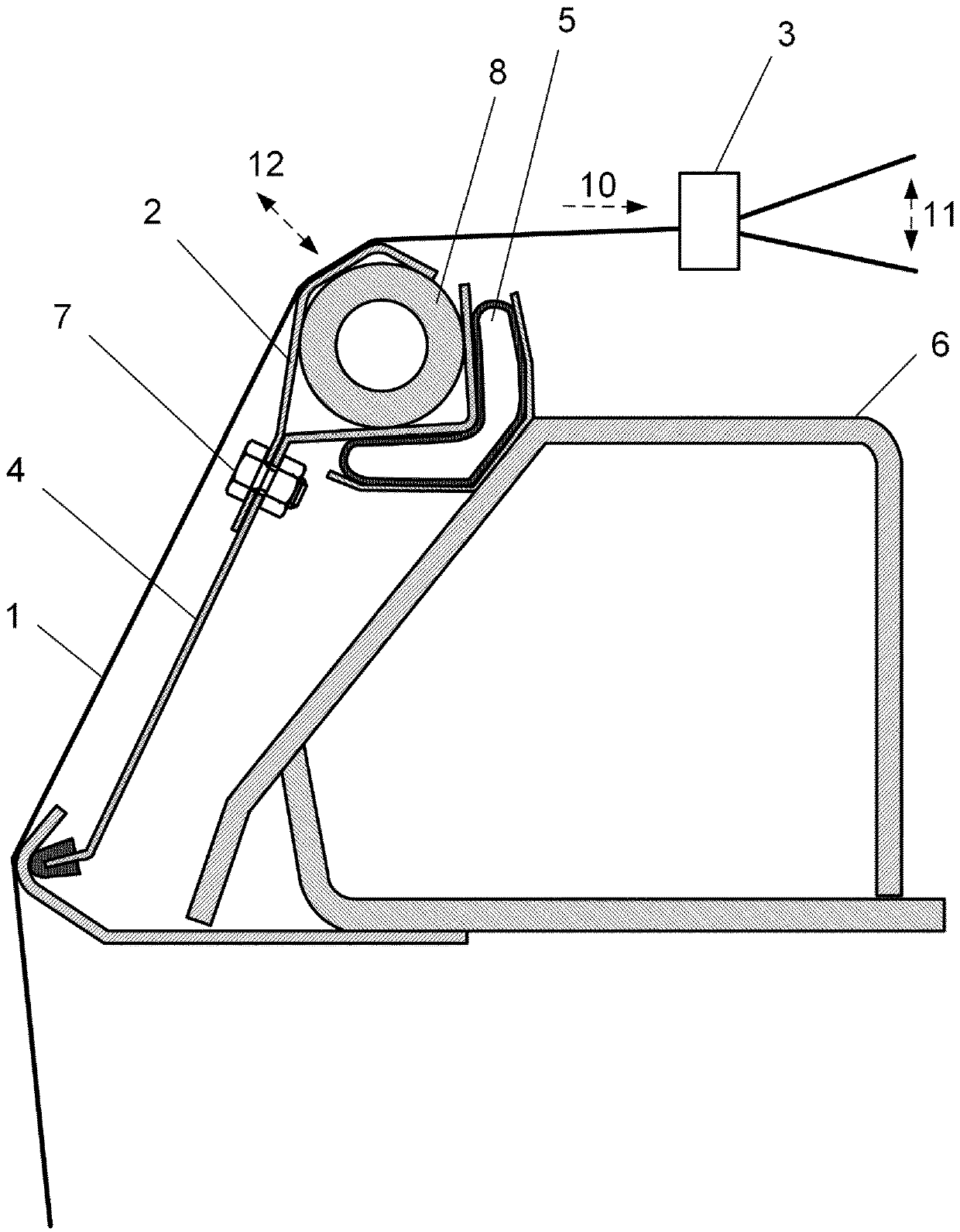

[0034] figure 1 An embodiment of the weaving machine according to the invention is shown in a sectional view, where the viewing direction is in the weft direction onto the rear of the machine. Starting from a not shown warp beam, the warp thread 1 is guided around a deflection element 2 and from there—via a device for monitoring the warp thread 3—is fed to the front of the weaving machine and to the shed for shedding and reed beat-up. element.

[0035] In the present example, the deflection element 2 is embodied as a bent sheet metal. It is now screwed together with a support element 4 in the form of a bent sheet metal, to which an air bellows 5 is attached at one end, while the other end is supported or supported at an articulation point in the frame of the weaving machine 6 .

[0036] Here, the air bellows 5 forms a spring element on which the deflection element 2 is connected to the weaving machine in such a way that when a force is applied or imposed on the deflection el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com