Cable secondary wiring layered peeling arrangement method

A secondary wiring and cable technology, which is applied to equipment for dismantling/armored cables, equipment for connecting/terminating cables, circuits, etc., which can solve problems affecting the construction quality of substations, non-standard cable head production, and unclear cable labels. and other problems, to achieve the effect of easy to find the cable number, reasonable wiring, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

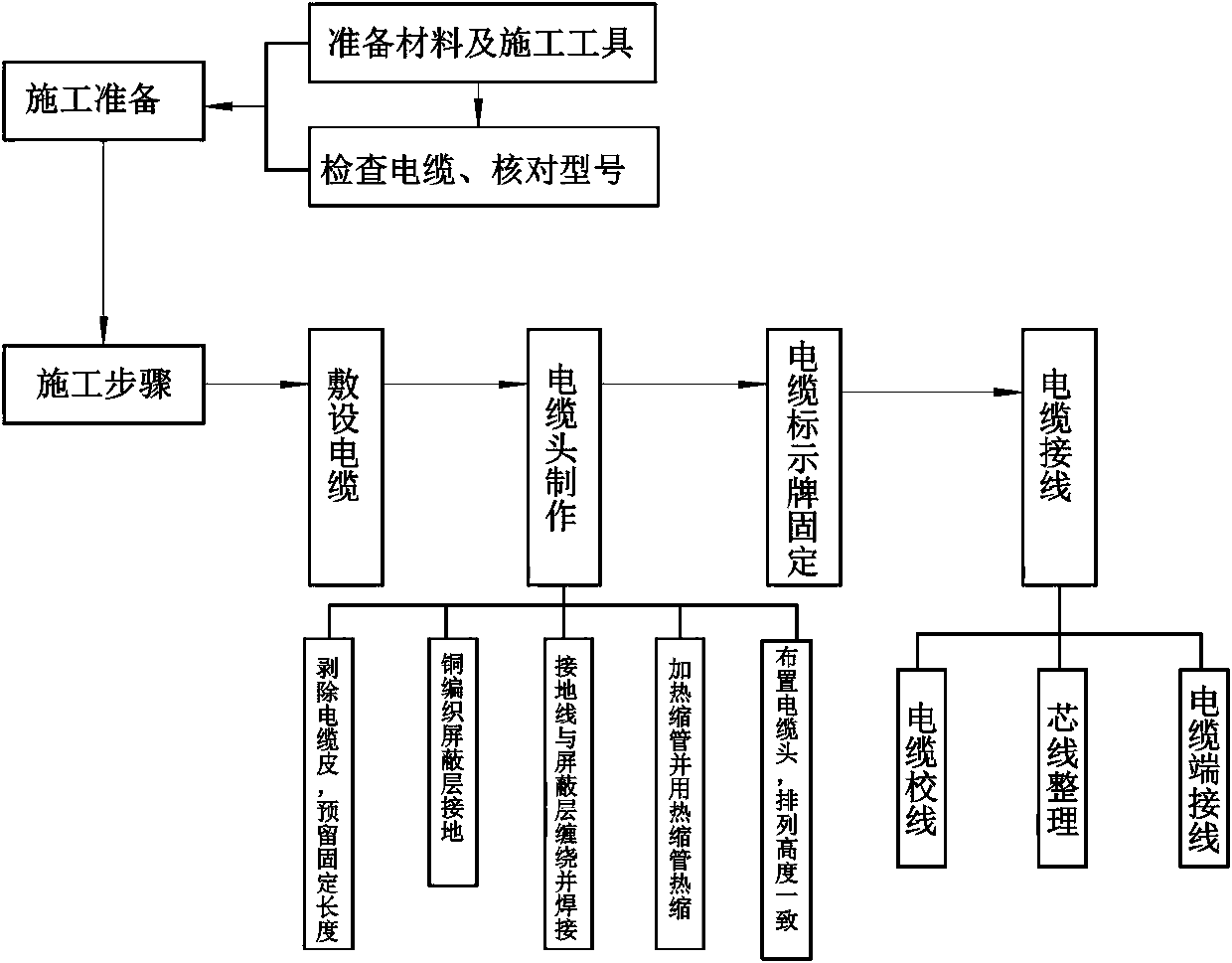

[0045] Example: A layered stripping arrangement method for secondary wiring of a cable, the specific steps are as follows:

[0046] A. Construction preparation:

[0047] 1) Prepare consumable materials and construction tools required for the construction of secondary wiring;

[0048] 2) Check the construction drawings and cable inventory, check the specifications and models, and check the appearance of no damage;

[0049] B. Operation steps:

[0050] 1) Laying cables:

[0051] a. Divide the cables on the left and right wiring sides, and pass the cables through the cabinet one by one; strip off the outer skin and steel armor of the cable near the plane of the cable hole in the screen cabinet;

[0052] b. Weld the steel armored ground wire, and wrap the welding place neatly with insulating self-adhesive tape;

[0053] c. Fix the cables on the horizontal support of the screen cabinet and arrange them, and record the arrangement order;

[0054] 2) Cable head production:

[0055] a. Strip the cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com