Forming workshop energy-saving dispatching method based on genetic simulated annealing algorithm

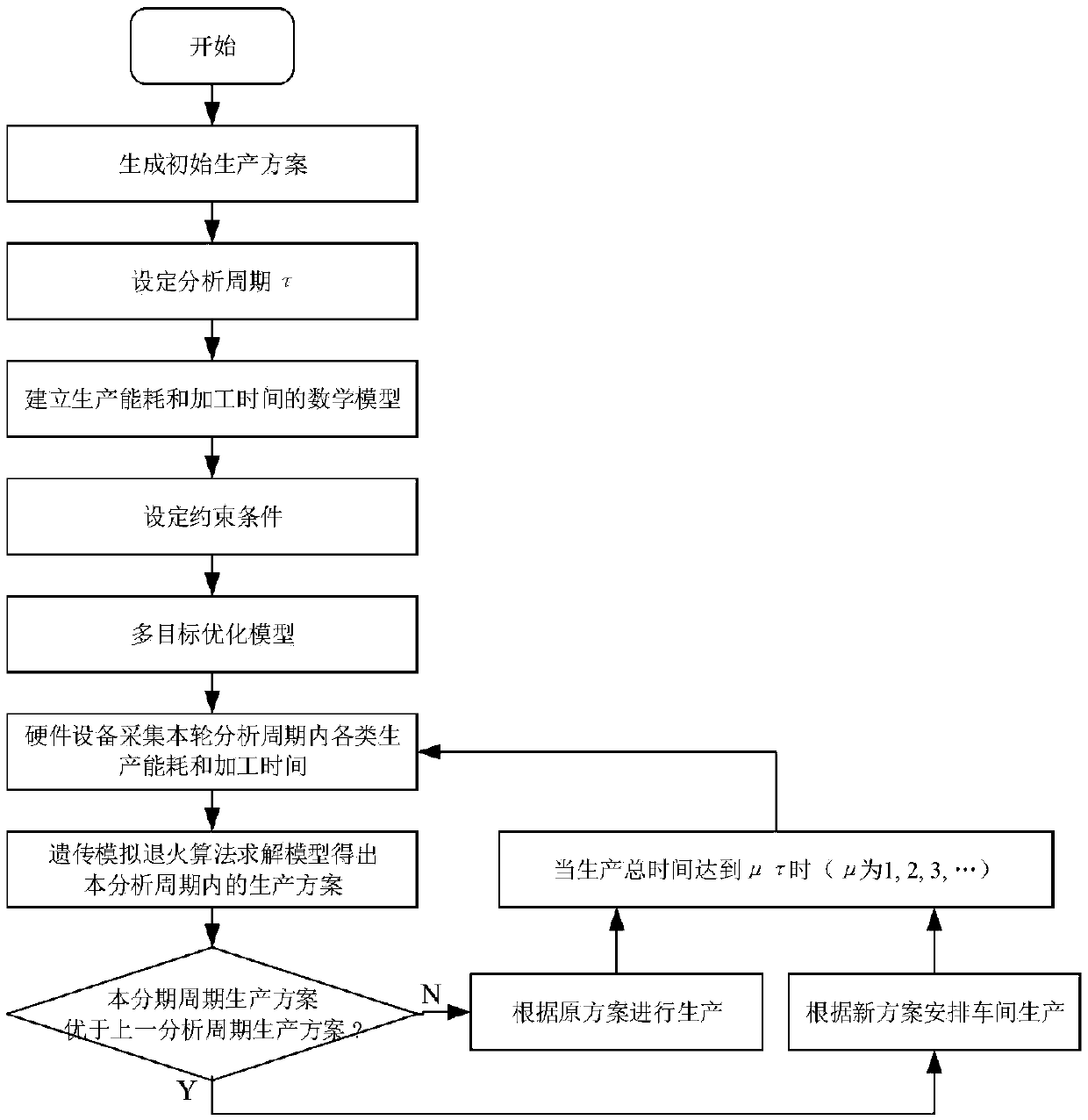

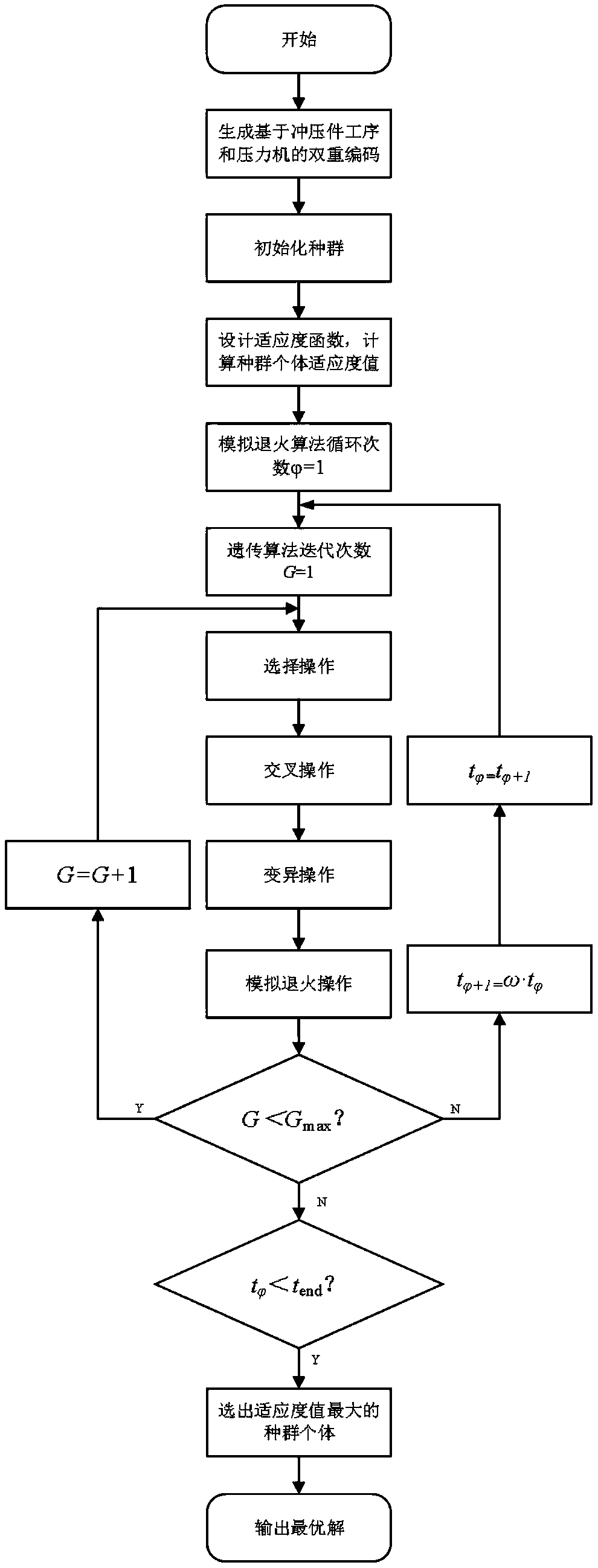

A simulated annealing algorithm and simulated annealing technology, applied in the field of energy-saving scheduling of forming workshops based on genetic simulated annealing algorithm, can solve problems such as feedback optimization, no workshop production, and no scheduling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In this embodiment, the press machine, including a punch press and a hydraulic press, is a versatile press machine with a delicate structure. With a wide range of uses and high production efficiency, the press can be widely used in cutting, punching, blanking, bending, riveting and forming processes. It can be processed by applying strong pressure to the metal blank to cause the metal to undergo plastic deformation and fracture. into parts. The press is the means of production and the material basis of the machinery manufacturing industry. Its quality, technical level and manufacturing cost are directly related to the development of the machinery manufacturing industry.

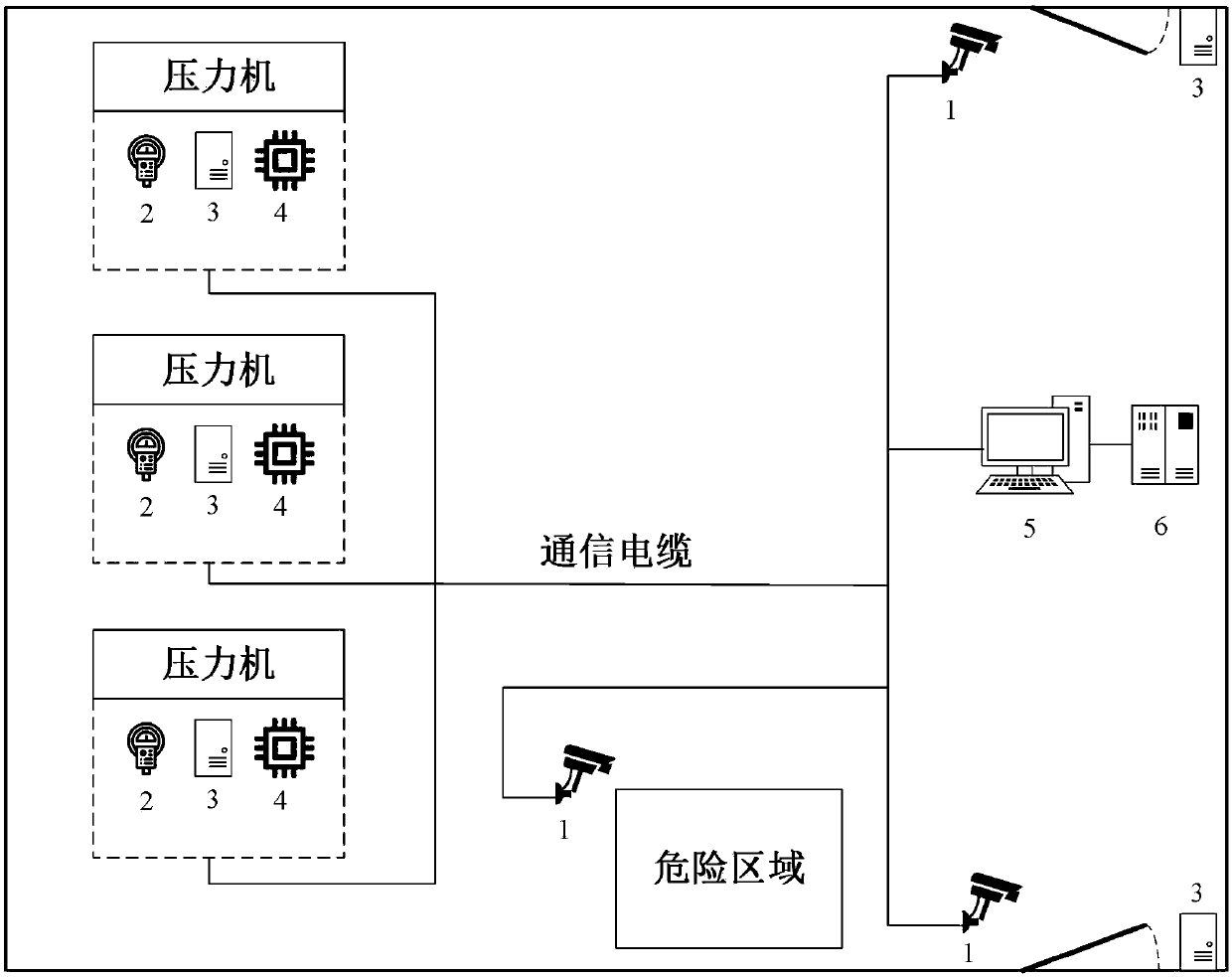

[0050] figure 2 It is a schematic diagram of the application workshop of the scheduling method based on the energy-saving scheduling method of the forming workshop based on the genetic simulated annealing algorithm, including video monitoring equipment 1, press information collection equipment 2, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com