High-gravity true triaxial rock loading experiment device and method

A loading test device and a technology for loading experiments, which are applied in the field of hypergravity true triaxial rock loading test devices, can solve the problems of difficulty in providing a large amount of data for model experiments, strict requirements for acoustic emission technology, and limited crack identification accuracy, so as to save materials and reduce costs. Centrifuge load, cost reduction, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

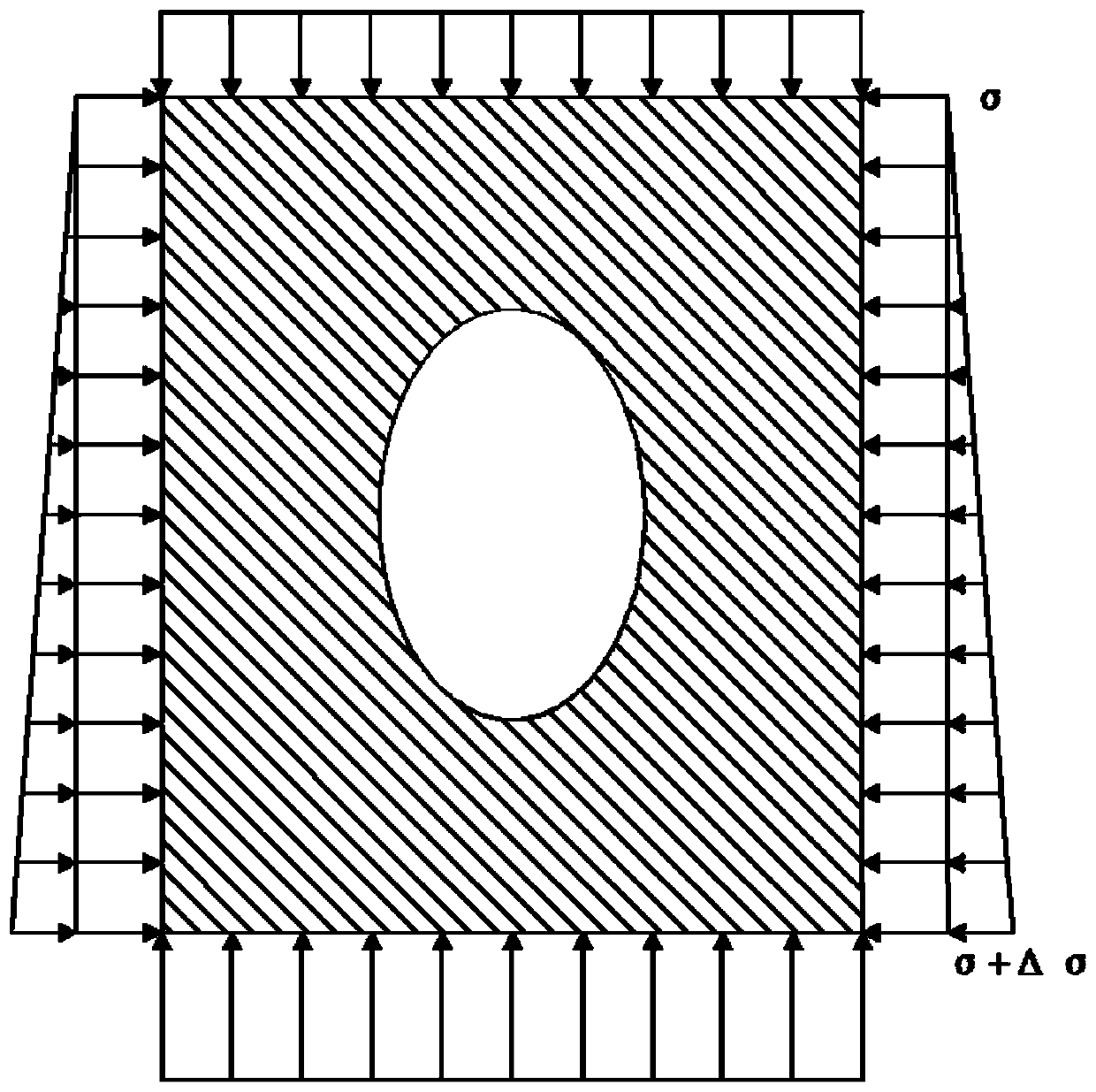

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

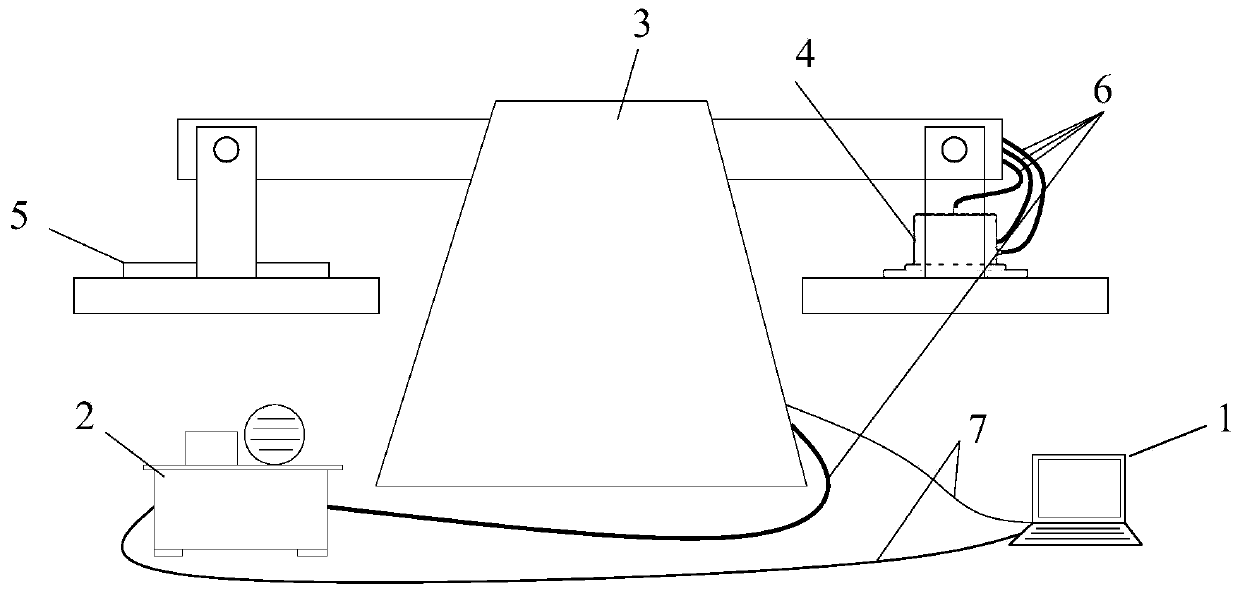

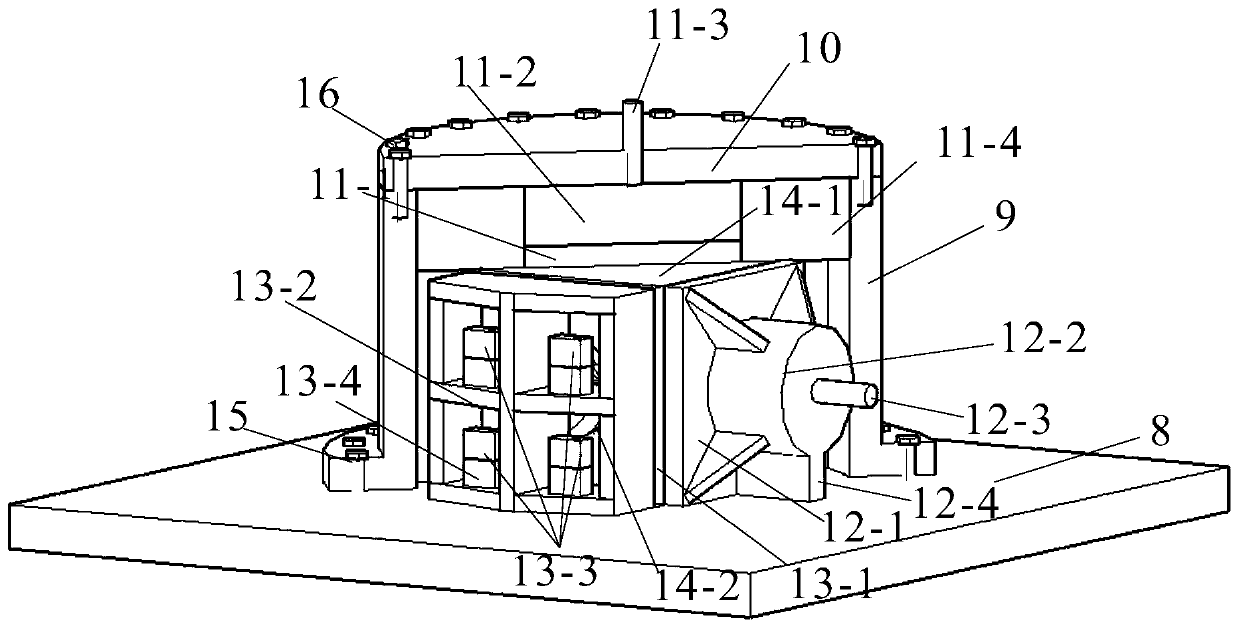

[0043] Such as Figure 2-4 As shown, a high-gravity true triaxial rock loading test device proposed in this embodiment includes a control center 1, a ground oil source 2, a centrifuge 3, a true triaxial loading test device 4, a counterweight 5, and a high-pressure oil pipe 6 , cable 7.

[0044] The true triaxial loading test device 4 includes: a bottom plate 8, a triaxial chamber 9, a triaxial chamber top cover 10, an axial principal stress loading device, a first lateral principal stress loading device, a second lateral principal stress loading device, a A transparent reaction force observation device, a second transparent reaction force observation device, an underground cavern surrounding rock sample 14-1, a triaxial chamber fixing bolt 15, and a triaxial chamber roof fixing bolt 16.

[0045] The triaxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com