A floor-standing air mechanical filter for a textile workshop

A mechanical filter, floor-standing technology, applied in the field of air purification, can solve the problems of large floor space and high equipment operating costs, and achieve the effect of high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

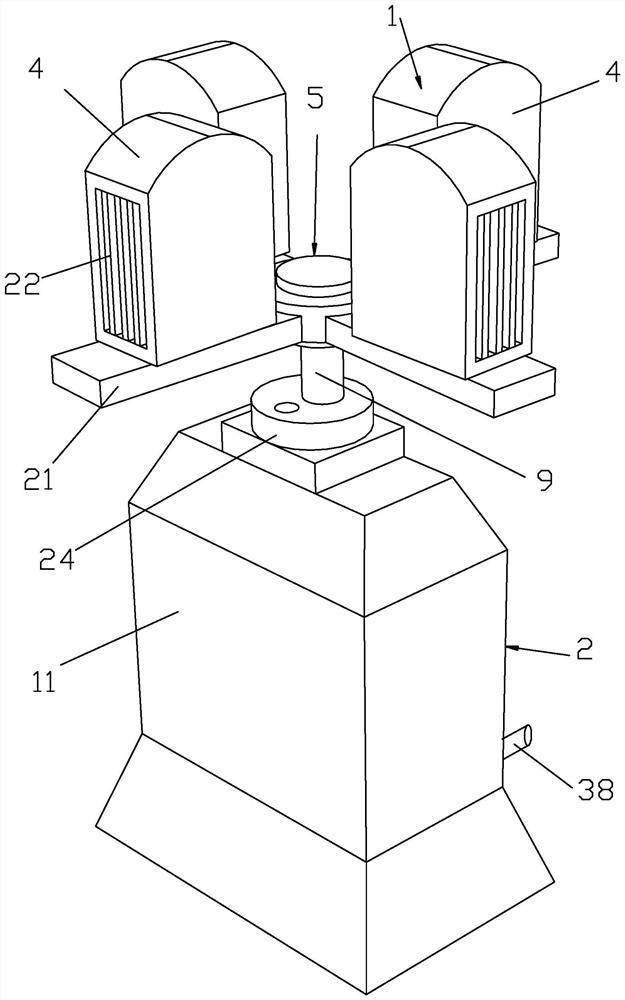

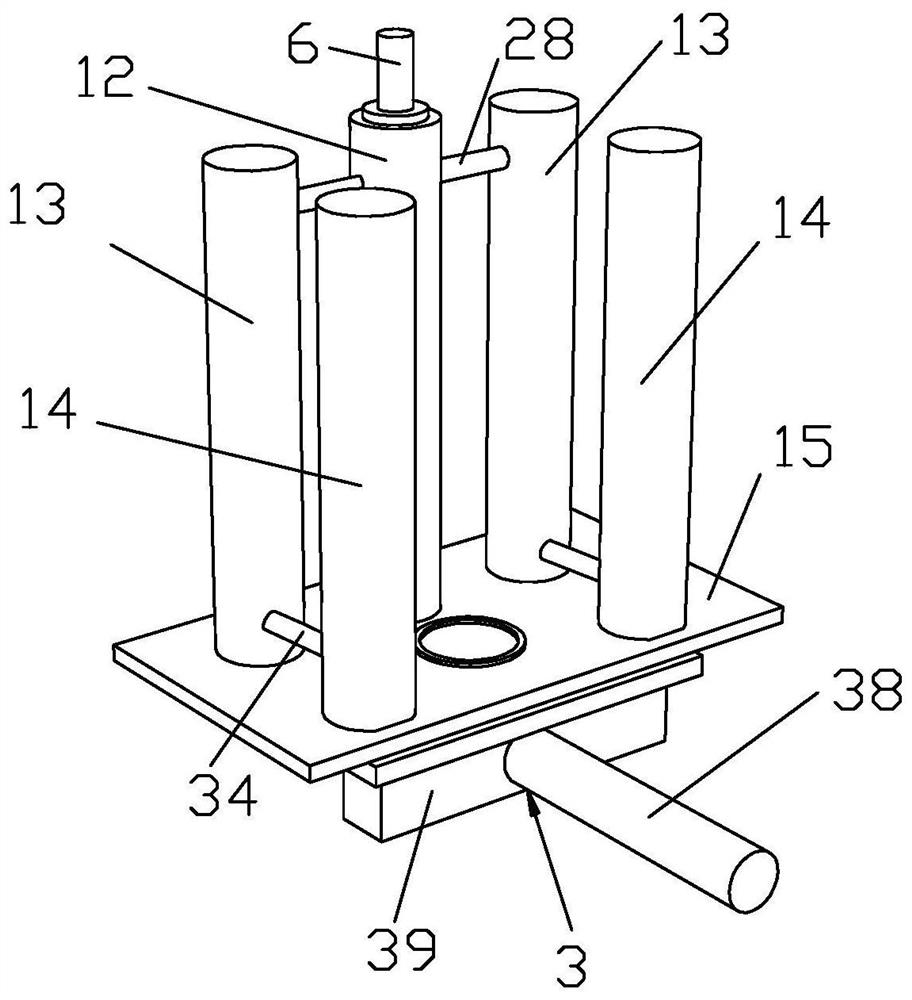

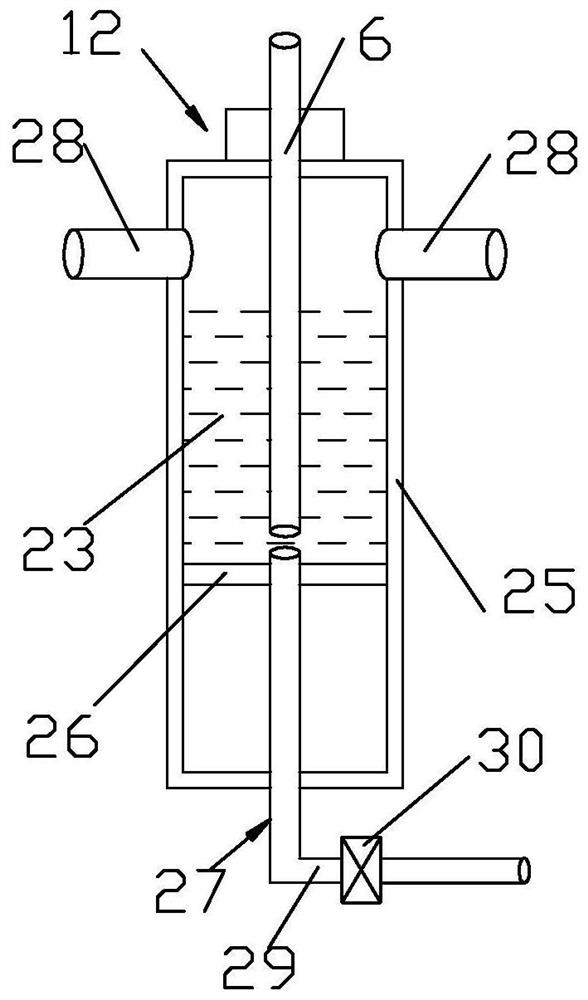

[0029] like Figure 1 to Figure 9 Shown is a floor-standing air mechanical filter for a textile workshop of the present invention, comprising an air inlet device 1, a purification device 2 and an air outlet device 3, and the air inlet device 1 includes an air inlet 4 and a rotator 5, and the air inlet 4 is installed on the top of the rotator 5, the air guide pipe is connected under the air inlet 4, the rotator 5 includes a connecting mechanism 7, a rotator 8 and a sleeve 9, the bottom of the rotator 8 is connected with the connecting mechanism 7, and the rotator 8 is connected with a rotating shaft 10, the sleeve 9 is sleeved on the outside of the rotating shaft 10, the diameter of the sleeve 9 is greater than the diameter of the rotating shaft 10, the purification device 2 includes a casing 11, a water filter chamber 12, a drying chamber 13 and a solid state Filter chamber 14, installation plate 15 is installed in the inside of housing 11, and installation plate 15 divides ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com