Water pump assembly device

An assembly and water pump technology, which is applied to the components, pumps, and pump elements of the pumping device for elastic fluids, can solve the problems of reduced water sealing effect, high maintenance cost, wear of rotating rings and stationary rings, etc. The effect of preventing the damage of the vehicle heat exchange water pump, reducing the maintenance cost and reducing the maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

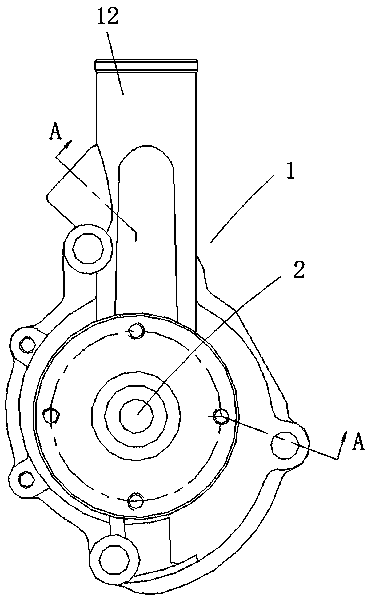

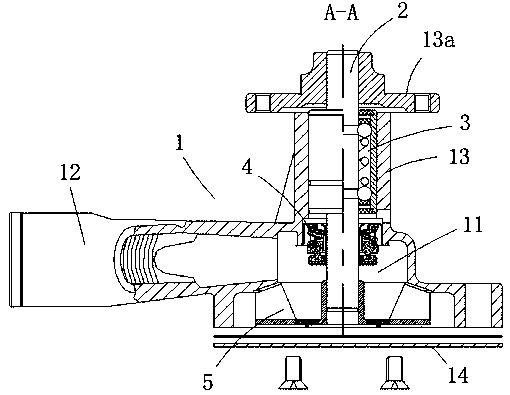

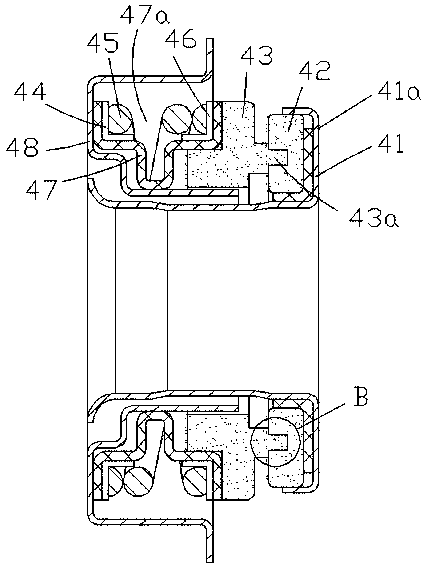

[0030] A water pump assembly device of the present invention, which includes a pump casing main body 1, an impeller cavity 11 is provided in the middle of the pump casing main body 1, and the pump casing main body 1 also includes a water inlet 12, a water outlet and a pump body installation pipe 13, and the inlet The water part 12, the water outlet and the pump body installation pipe 13 are all in communication with the impeller cavity 11, the lower end of the impeller cavity 11 is open, and the cover 14 is fixed on the lower end of the impeller cavity 11 by bolts to seal the lower end of the impeller cavity 11, and the water inlet part One end of 12 communicates with the middle part of the upper end of the impeller chamber 11, the lower end of the pump body installation pipe 13 opens in the upper middle part of the impeller chamber 11, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com