Pneumatic anchor rod drilling machine operation positioning device and method for geotechnical engineering

A rock bolter and geotechnical engineering technology, applied in earthwork drilling, supporting devices, drilling equipment, etc., can solve the problems of rock bolter vibration, pneumatic rocker drill pipe deviation, and single function of the drilling rig, etc., to ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following describes the specific embodiments of the present invention to facilitate those skilled in the art to understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments, for those of ordinary skill in the art, as long as various changes These changes are obvious within the spirit and scope of the present invention defined and determined by the appended claims, and all inventions and creations that utilize the concept of the present invention are protected.

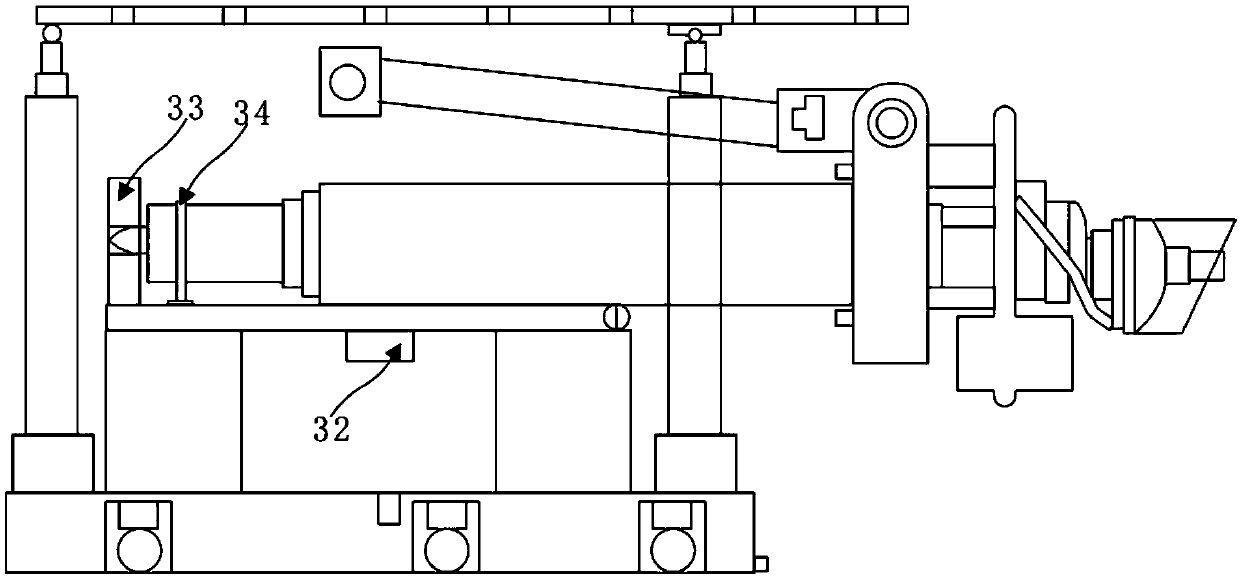

[0034] Such as figure 1 with figure 2 As shown, the operation positioning device of the pneumatic bolting rig for geotechnical engineering includes a square base 2 and a square base 5. A support platform 21 and at least one first electric push rod 22 are installed on one side of the top surface of the square base 2. On the other side are installed a first scissor lift platform 23 with a minimum height equal to the height of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com