Method for preparing polyurethane sheet from sintering flue gas desulfurized ash

A technology for sintering flue gas and polyurethane, applied in chemical instruments and methods, inorganic chemistry, calcium carbonate/strontium/barium, etc., can solve the problems of unstable product performance, unadjustable components, etc. The effect of mitigating negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

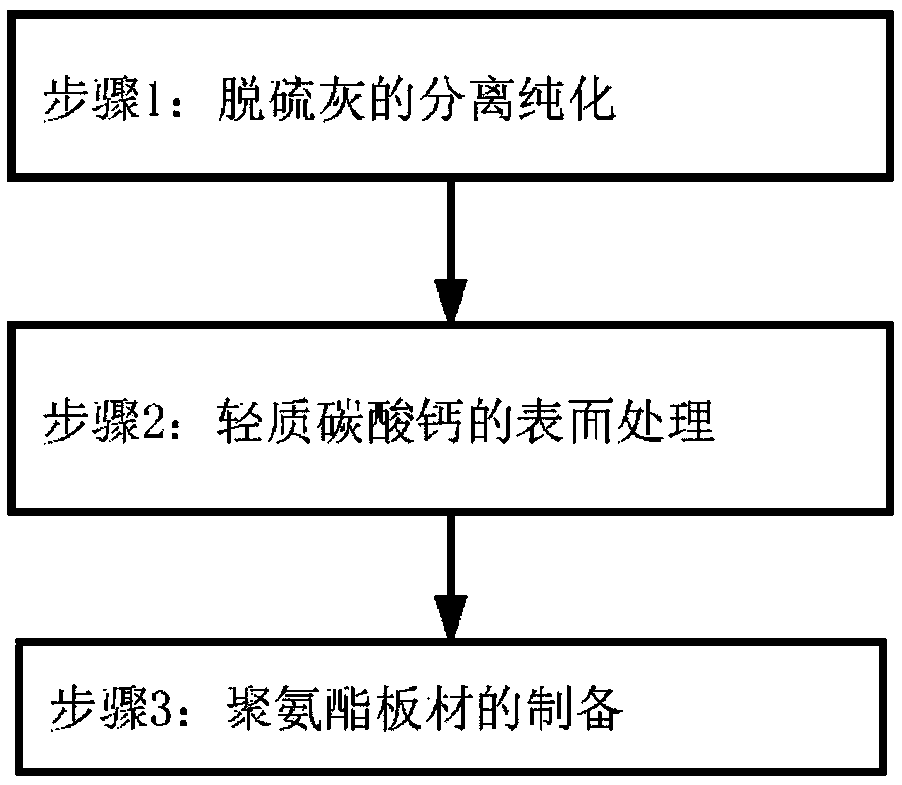

[0038] A preferred embodiment of a method for preparing polyurethane boards by sintering flue gas desulfurization ash provided by the present invention is as follows: figure 1 shown, including the following steps:

[0039] Step 1: Separation and purification of desulfurization ash;

[0040] Step 2: surface treatment of light calcium carbonate;

[0041] Step 3: Preparation of polyurethane sheet.

[0042] Step 1 includes the following steps:

[0043] Step 1.1: Take 100 parts by mass of desulfurized ashes and 280 parts by mass of water, put them into the first reactor, stir and react at room temperature for 1 hour, and the reaction stirring speed is 100 rpm; the components of the desulfurized ashes used for the reaction include calcium hydroxide, Calcium carbonate, calcium sulfite; the mass percentage of calcium hydroxide is 8%, the mass percentage of calcium carbonate is 20%, the mass percentage of calcium sulfite is 60%, other such as silicon dioxide, iron oxide, potassium o...

Embodiment 2

[0058] Another preferred embodiment of the present invention comprises the following steps:

[0059] Step 1: Separation and purification of desulfurization ash;

[0060] Step 2: surface treatment of light calcium carbonate;

[0061] Step 3: Preparation of polyurethane sheet.

[0062] Step 1 includes the following steps:

[0063] Step 1.1: Take 100 parts by mass of desulfurized ashes and 280 parts by mass of water, put them into the first reactor, stir and react at room temperature for 1 hour, and the reaction stirring speed is 100 rpm; the components of the desulfurized ashes used for the reaction include calcium hydroxide, Calcium carbonate, calcium sulfite; the mass percentage of calcium hydroxide is 10%, the mass percentage of calcium carbonate is 23%, the mass percentage of calcium sulfite is 60%, other such as silicon dioxide, iron oxide, potassium oxide, chloride Calcium, etc. total 7%;

[0064] Step 1.2: Pass carbon dioxide gas into the first reactor, continue to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com