A kind of barnacle gum protein dialysis process and the method for obtaining two different types of proteins

A technology of colloidal protein and barnacles, which is applied in the dialysis process of biological materials and the field of obtaining protein, can solve the problems of low production of colloidal protein and long dialysis time, and achieve the goals of shortening dialysis time, improving the application range, and high gelation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

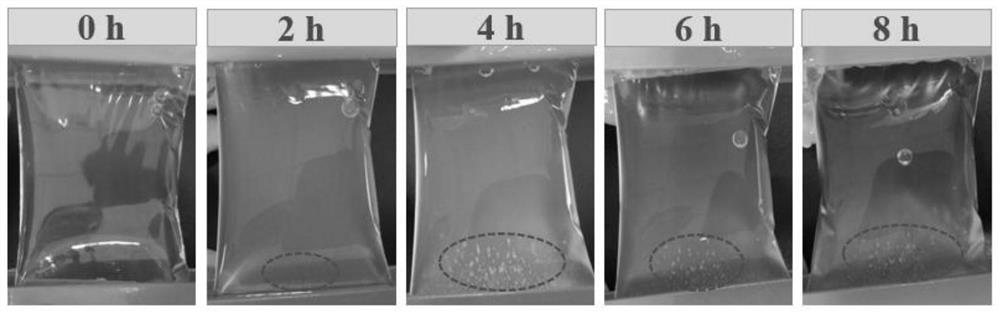

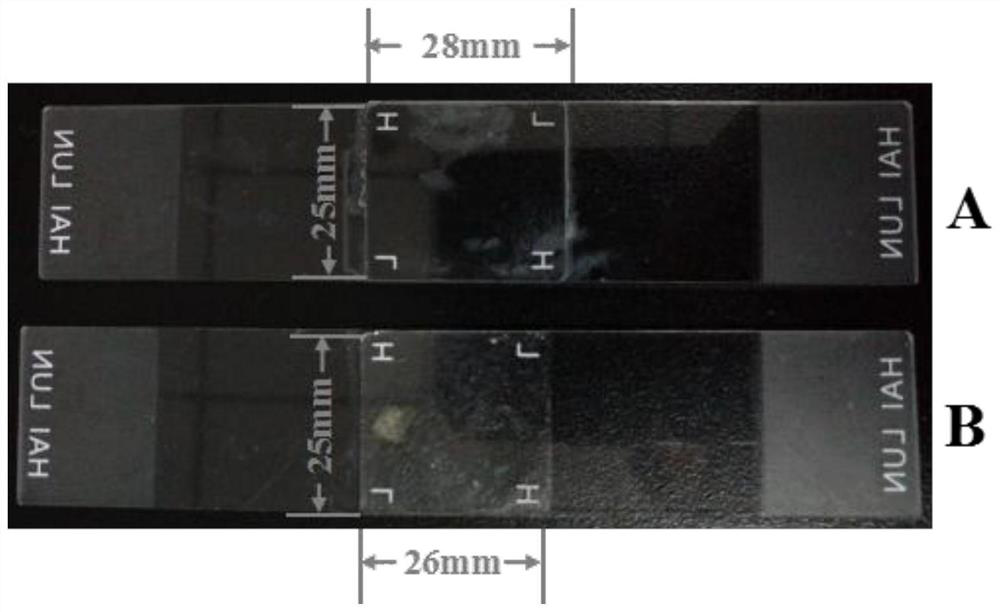

[0034] A Trx-Balcp19k protein dialysis process, comprising the following steps: putting the Trx-Balcp19k protein solution with a concentration of 2.11 mg / mL and a volume of 14 mL obtained by affinity chromatography (see patent CN105031717A) into a dialysis bag , under magnetic stirring, placed in an environment of 4°C for dialysis with deionized water as the dialysate, during the dialysis process, the dialysate was replaced every 2 hours, and the dialysate was continued for 8 hours (the ionic strength in the dialysate at this time was 173 μs / cm ). like figure 1As shown, as the dialysis time prolongs, viscous jelly will appear on the inner wall of the dialysis bag, and it is mainly concentrated in the middle and lower part of the dialysis bag. It should be noted that dialysis itself will lose a part of protein, and according to past experience, the loss rate is about 30%.

[0035] In this embodiment, after the dialysate was replaced for the first time, the protein solution co...

Embodiment 2

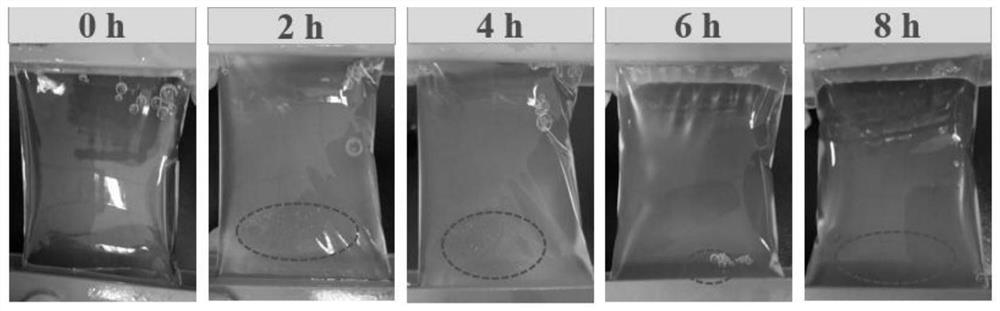

[0043] A Trx-Balcp19k protein dialysis process, comprising the following steps: putting the Trx-Balcp19k protein solution with a concentration of 2.11 mg / mL and a volume of 14 mL obtained by affinity chromatography (see patent CN105031717A) into a dialysis bag , under magnetic stirring, place in an environment of 4°C and use deionized water as the dialysate for dialysis, and change the dialysate every 2 hours during the dialysis process (the time for changing the dialysate needs to meet the requirements of the gelation rate at the same time, the same below) , and after 4 hours of dialysis, the viscous jelly was collected from the inner wall of the dialysis bag with the tip of a pipette gun, and the dialysis was continued for 8 hours (at this time, the ionic strength in the dialysate was 149.3 μs / cm). like image 3 As shown, as the dialysis time prolongs, viscous jelly will appear on the inner wall of the dialysis bag, and it is mainly concentrated in the middle and lower part ...

Embodiment 3

[0050] A Trx-Balcp19k protein dialysis process, comprising the following steps: putting the Trx-Balcp19k protein solution with a concentration of 2.37 mg / mL and a volume of 15 mL obtained by affinity chromatography (see patent CN105031717A) into a dialysis bag , under magnetic stirring, placed in an environment of 4°C for dialysis with deionized water as the dialysate, during the dialysis process the dialysate was replaced every 2 hours, and after 4 hours of dialysis, use the tip of a pipette to collect the viscous glue from the inner wall of the dialysis bag Shaped matter, continuous dialysis for 8h.

[0051] In this embodiment, after the dialysate was replaced for the first time, the protein solution concentration was about 1.73mg / mL, the volume was 16.3mL, and the gelation rate was about 7.8%; after the dialysate was replaced for the second time, the protein solution concentration was about 1.32 mg / mL, the volume is 17.1mL, the gelation rate is about 19.5%; after the third ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com