Positioning mechanism of wine bottle after covered

A technology for upright positioning and wine bottles, which is applied in the field of wine making, can solve problems such as insufficient cover depth, influence on production progress, and lax cap screwing, and achieve the effects of reducing screw cap failure rate, improving production efficiency, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

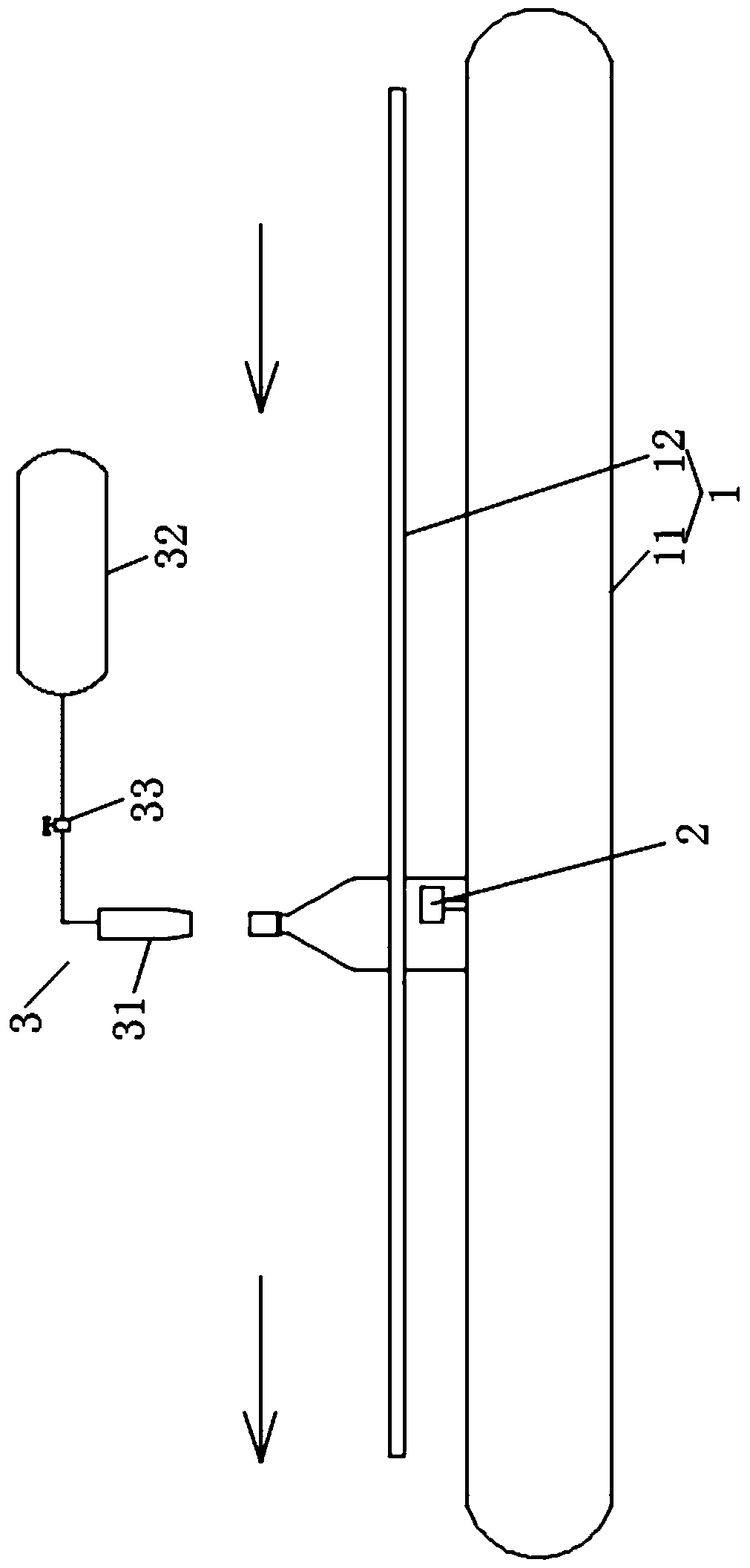

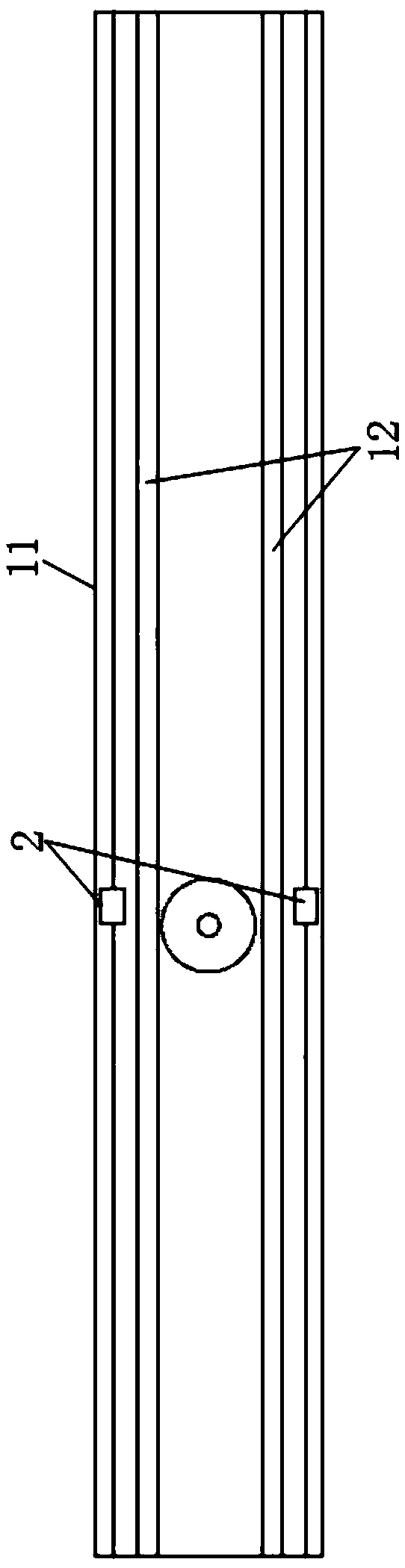

[0025] Example: such as figure 1 and 2 As shown, the rear alignment mechanism of the wine bottle cover in this embodiment includes a conveying device 1, a photoelectric sensor 2, an air blow alignment mechanism 3 and a controller;

[0026] The above-mentioned blowing normal position mechanism 3 has a blowing nozzle 31, and the above-mentioned blowing nozzle 31 is arranged on the top of the conveying surface of the above-mentioned conveying device 1, and its blowing direction is downward, which is used for the mouth of the wine bottle conveyed below it. The bottle cap is blown down to the correct position;

[0027] The above-mentioned photoelectric sensor 2 is arranged on the above-mentioned conveying device 1, and is used to detect whether there is a wine bottle passing under the above-mentioned blowing nozzle 31;

[0028] The above-mentioned controller is respectively connected with the above-mentioned photoelectric sensor 2 and the above-mentioned blowing positive position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com