Jack with brake device

A jack with brake technology, which is applied in the direction of lifting devices, etc., can solve problems such as potential safety hazards, and achieve the effect of increasing safety protection and preventing sudden drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

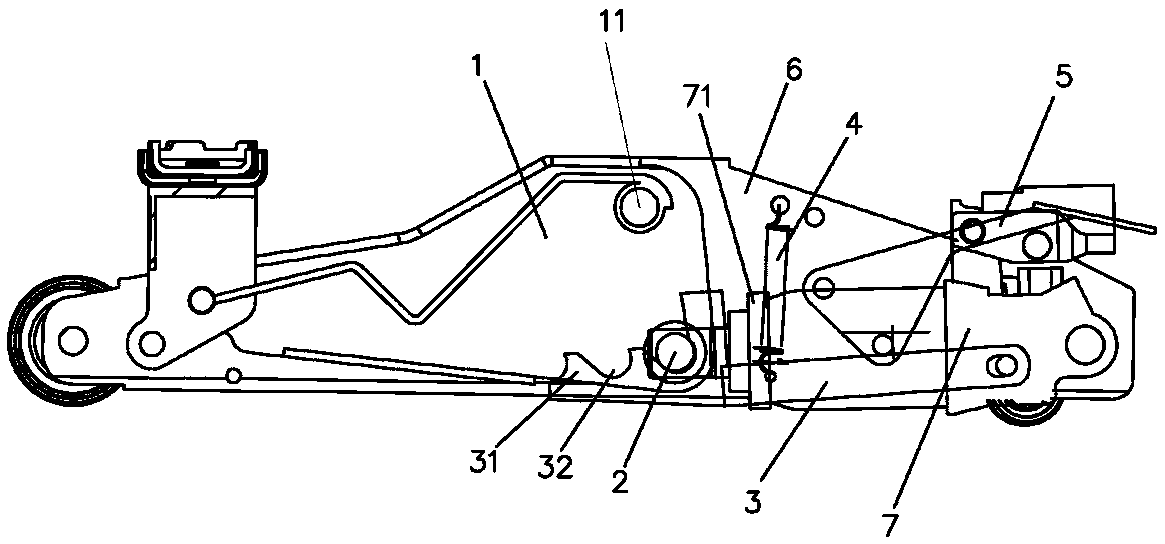

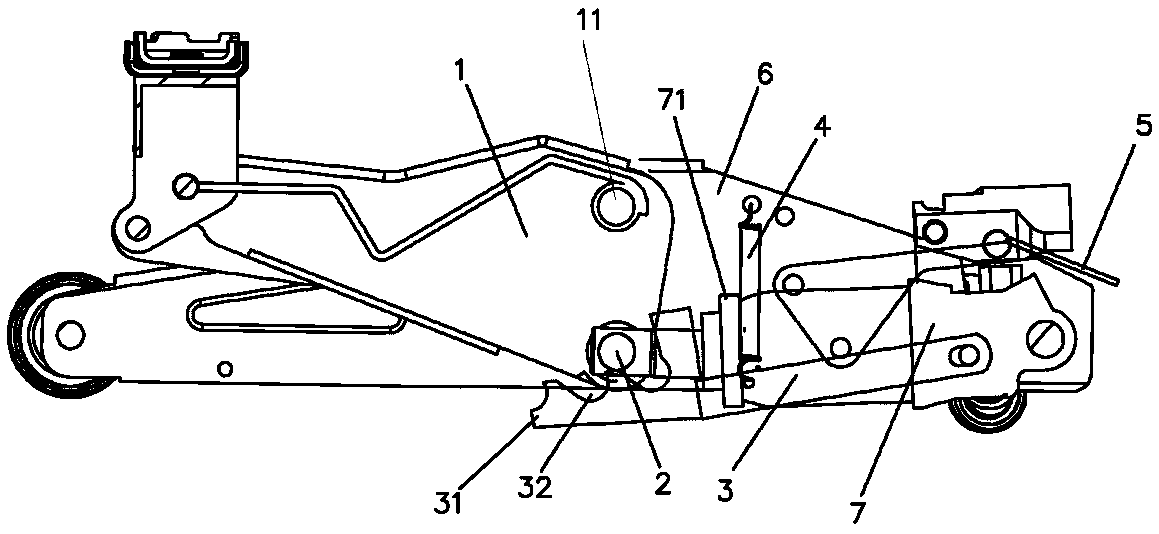

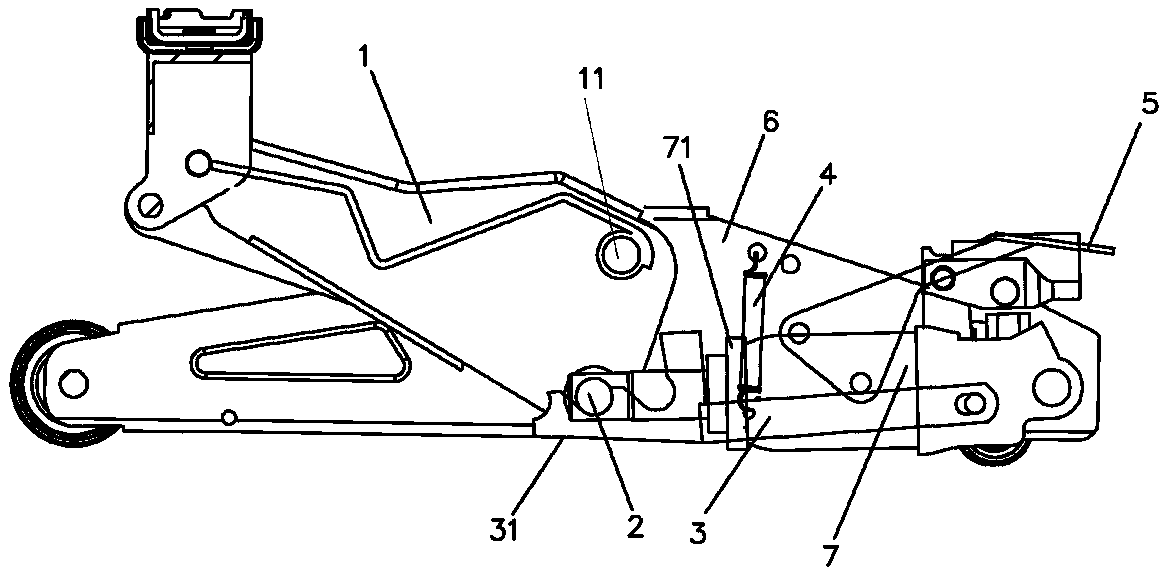

[0018] like figure 1 As shown, a jack with a braking device includes a base, and left and right wall board parts 6 are arranged on the left and right sides of the base, and an arm part 3 and an oil pump device 7 are arranged between the left and right wall board parts 6. The above-mentioned lifting part 1 is pivotally connected to the left and right wallboard parts 6, the rear part of the lifting part 1 is movably connected with the piston rod 72 of the oil pump device 7, and the front part of the lifting part 1 is provided with a top arm, which is characterized in that: A stopper part 3 and a pedal part 5 for controlling the stopper part are also arranged between the left and right wallboard parts 6. The stopper part includes a stopper arm, and the rear end of the stopper arm is pivotally connected to the base or the left and right sides. On the wall board part, the front section of the stop arm is provided with an anti-slip part 31, and the position of the anti-slip part cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com