An impact-resistant curved bar lattice sandwich panel structure

A lattice structure, impact-resistant technology, applied in layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of large impact stress of straight rods, weaken the mechanical performance of structures, etc., and achieve impact resistance Excellent, weight-reducing, and stress-peak-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

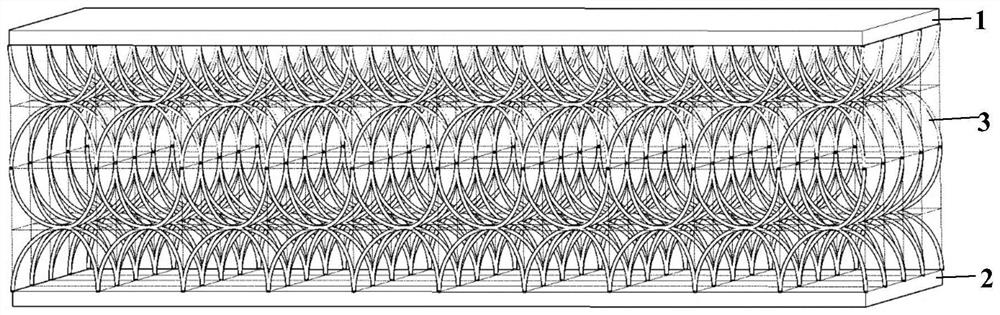

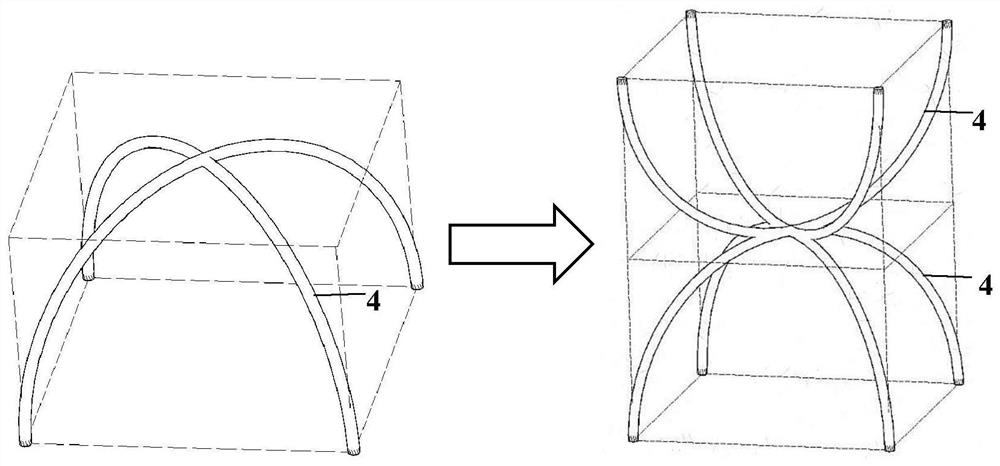

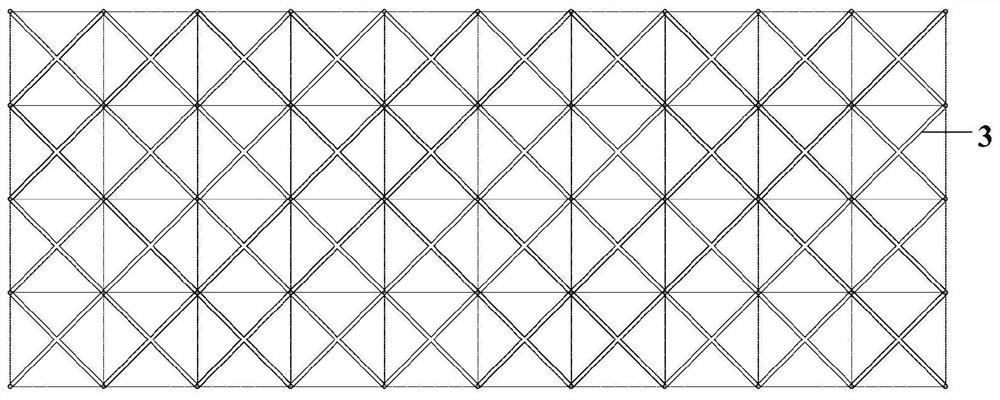

[0032] Embodiment 1: as Figure 1~3 Shown is a four-layer grid type impact-resistant curved bar lattice sandwich panel structure. The upper surface plate 1 and the lower surface plate 2 are plates made of glass fiber reinforced plastics. The single curved bar structure 4 adopts a regular quadrilateral configuration, and the material is made of glass steel. Regular quadrilateral single curved rod substructure 4 as first figure 2 Extend along the Z direction as shown, and then extend it along the XY plane to finally form the core layer 3 of the four-layer grid-type impact-resistant curved rod lattice sandwich panel structure, and finally form the four-layer grid-type impact-resistant curved rod The core layer 3 of the lattice sandwich panel structure is combined with the upper panel 1 and the lower panel 2 of FRP to form a four-layer grid type impact-resistant curved bar lattice sandwich panel structure. The core layer of the four-layer grid-type impact-resistant curved rod la...

Embodiment 2

[0033] Embodiment 2: as Figure 4~6 Shown is a single-layer honeycomb impact-resistant curved bar lattice sandwich panel structure. The upper surface plate 1 and the lower surface plate 2 are plates made of reinforced concrete. The single curved bar structure 4 adopts a regular hexagonal configuration, and the material is steel. Extend the regular hexagonal single curved rod substructure 4 along the XY plane to form a single-layer honeycomb curved rod lattice structure core layer 3, and then connect the formed single-layer honeycomb curved rod lattice structure core layer 3 with the reinforced concrete upper surface 1 is combined with the lower surface plate 2 to form a single-layer honeycomb impact-resistant curved bar lattice sandwich panel structure. The core layer of the single-layer honeycomb curved rod lattice structure acts as a skeleton to support the upper and lower skins, so that the upper and lower skins have a certain bending stiffness. When the impact load is app...

Embodiment 3

[0034] Embodiment 3: as Figure 7~9 Shown is a double-layer triangular impact-resistant curved rod lattice sandwich panel structure, the upper surface plate (1) and the lower surface plate (2) are made of hard plastic plates, and the single curved rod substructure 4 adopts an equilateral triangle configuration, The material is hard plastic, and the equilateral triangular single curved rod structure 4 is first as Figure 8 Extend along the Z direction as shown, and then extend it along the XY plane to finally form the core layer 3 of the double-layer triangular impact-resistant curved bar lattice sandwich panel structure, and then form the double-layer triangular anti-impact curved bar lattice The core layer 3 of the sandwich panel structure is combined with the hard plastic upper panel 1 and the lower panel 2 to form a double-layer triangular impact-resistant curved bar lattice sandwich panel structure. The core layer of the double-layer triangular impact-resistant curved bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com