A method for improving the cured molding quality of L-shaped composite laminates

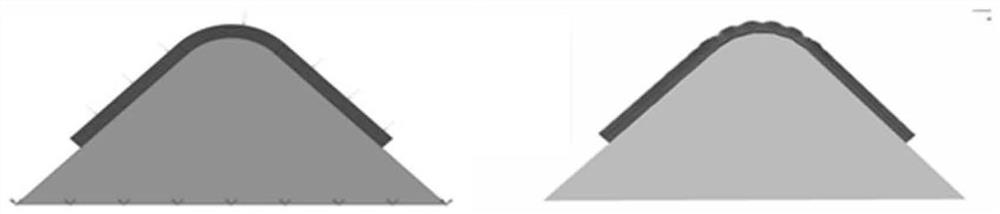

A composite material layer, curing molding technology, applied in the field of composite materials, can solve the problems of L-shaped composite material laminates, such as wrinkles, to avoid uneven pressure, suppress micro-buckling, and improve the effect of curing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

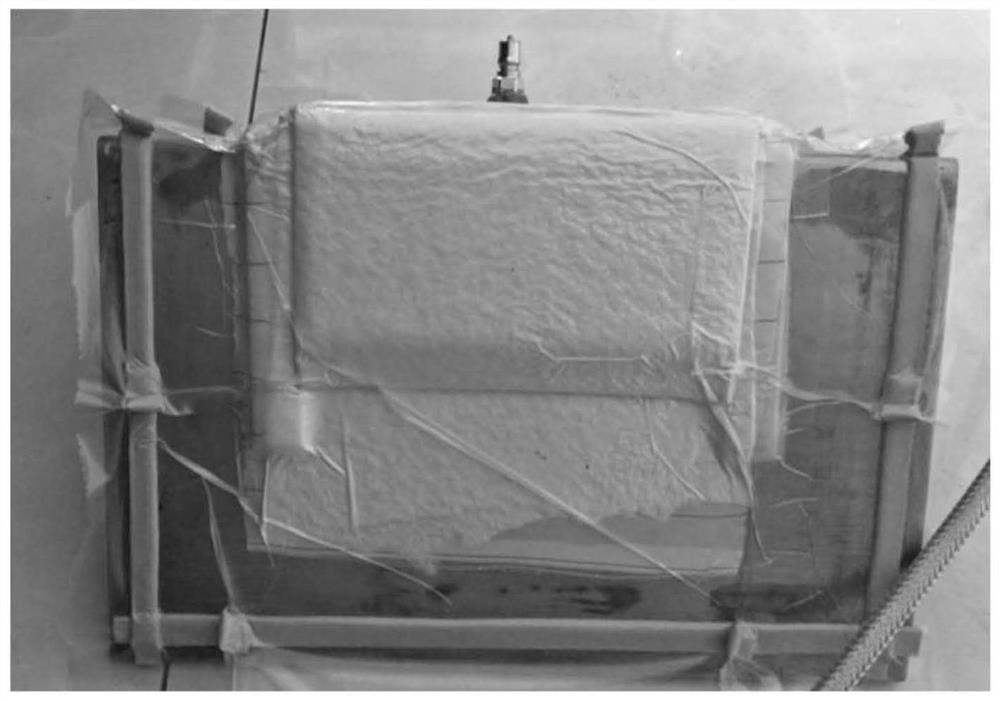

[0026] Example 1: Using elastic buffer soft mold to improve the surface quality of L-shaped sample in autoclave molding

[0027] This embodiment provides a method for improving the surface quality of a composite component with curvature, which specifically includes the following steps:

[0028] (1) According to the external dimensions of the L-shaped sample, the radius of the outer chamfer is 10mm, the length of the right-angled side is 100mm, and the width is 200mm. The inner radius of the elastic buffer soft mold is determined to be 10mm, the thickness is 10mm, the length of the right-angled side is 110mm, and the width is 10mm. 220mm, see the specific size diagram Figure 4 .

[0029] (2) Referring to the size of the elastic buffer soft film designed in (1), make a mold cavity for pouring. Then take 500g of silica gel and curing agent to blend according to the mass ratio of 100:15, and pour it into the cavity after defoaming. Wait 12 hours for the silicone to fully cure....

Embodiment 2

[0033] Example 2: Using elastic buffer soft film to improve the surface quality of L-shaped sample in autoclave forming

[0034] This embodiment provides a method for improving the surface quality of a composite component with curvature, which specifically includes the following steps:

[0035] (1) According to the design dimensions of the L-shaped sample, the radius of the outer chamfer is 14mm, the length of the right-angled side is 120mm, and the width is 220mm. , the thickness is 8mm and the specific size diagram is shown in Figure 7 .

[0036] (2) According to the external dimensions determined in step (1), the natural rubber elastic cushioning soft mold is customized, and its Shore hardness is required to be between 50±20HA, and the elongation at break is greater than 100%.

[0037] (3) After the elastic cushioning soft mold is finished, use a hollow needle to drill uniform vent holes with a diameter of 1mm and an interval of 8mm on the silicone pad, such as Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com