Activated carbon micro hole ultra-fine dust wind power screening device

A screening device, activated carbon technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problem of increasing bed resistance, reducing porosity, and reducing dust removal and desulfurization efficiency. and other problems, to achieve the effect of uniform gas flow field, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

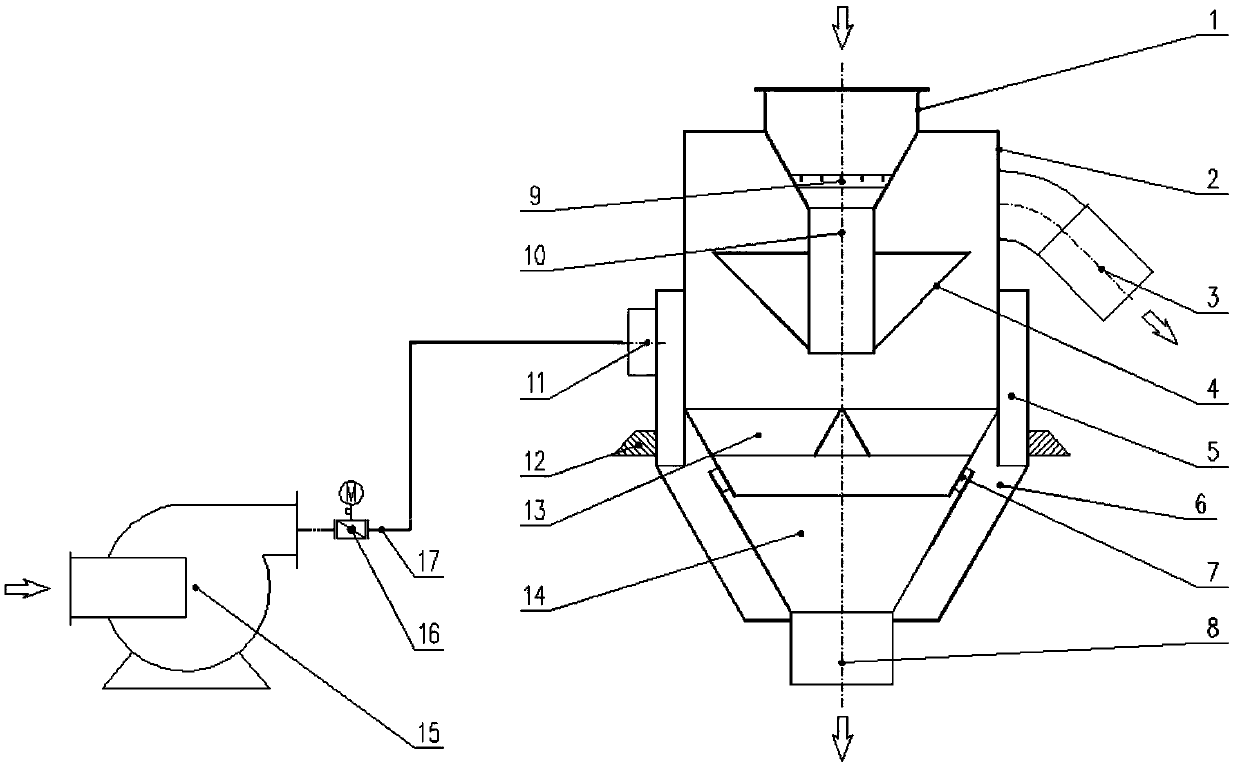

[0025] Example 1, such as figure 1 Shown:

[0026] An activated carbon microporous ultrafine dust wind screening device, comprising a housing 2, a feed inlet 1 at the top of the housing 2, and a discharge outlet 8 at the bottom of the housing 2, and a grid plate is arranged inside the feed inlet 1 9. The part where the feeding port 1 extends into the interior of the housing 2 is provided with a feeding pipe 10, and deflectors 4 are provided on both sides of the feeding pipe 10, and the housing 2 is provided with a distribution Cone bucket 13, the distribution cone bucket 13 is located directly below the deflector 4, the two sides of the distribution cone bucket 13 are provided with annular air distribution holes 7, and the discharge port 8 is located in the distribution cone Right below the bucket 13, a static pressure chamber 6 is provided on both sides of the housing 2, an air inlet cavity 5 is provided at the top of the static pressure chamber 6, and a fan 15 is provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com