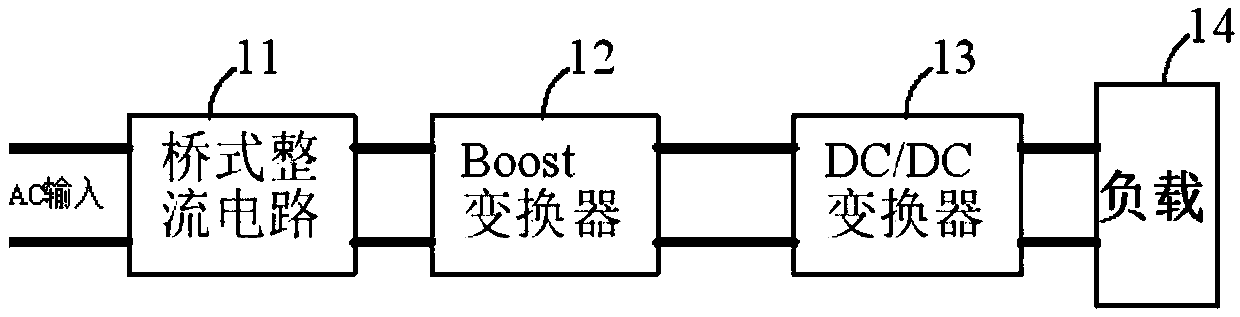

AC/DC power supply system and control method thereof

A technology of DC power supply and controller, applied in the direction of control/regulation system, electrical components, regulating electrical variables, etc., can solve the problem that the power supply system is difficult to work in the optimal working state, etc., to achieve convenient application, reduced voltage stress, Effects of low voltage specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

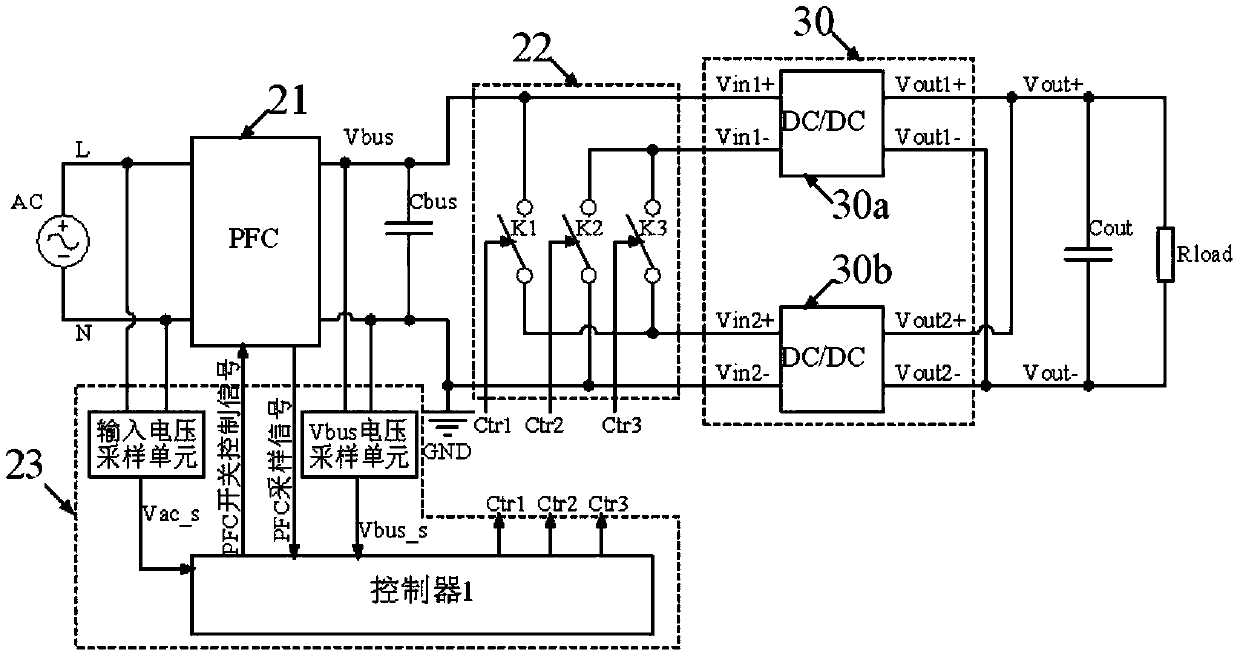

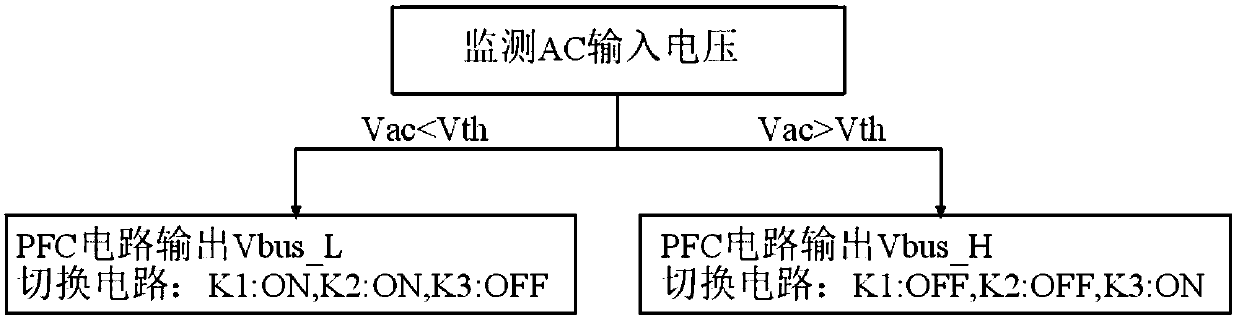

[0048] figure 2 Shown is the schematic circuit diagram of Embodiment 1 of the AC / DC power supply system of the present invention, the AC / DC power supply system includes an AC power supply, a power factor correction circuit 21 (referred to as a PFC circuit), a bus capacitor Cbus, a switching circuit 22, The control circuit 23, the DC / DC isolation power module 30, the output capacitor Cout and the output load Rload.

[0049] The DC / DC isolated power module 30 includes two complete power modules 30a and 30b, and 30a and 30b themselves have the function of loop regulation to control the output voltage. The two input terminals of the PFC circuit 21 are respectively connected to the L terminal and the N terminal of the AC power supply, and the output terminal outputs the bus voltage Vbus. The bus capacitor Cbus is connected between the output terminal of the PFC circuit and the ground. The input terminal of the switching circuit 22 is connected to the bus voltage Vbus, and 22 has...

no. 2 example

[0067] Figure 6 Shown is the circuit schematic diagram of the second embodiment of the AC / DC power supply system of the present invention, the AC / DC power supply system includes an AC power supply, a power factor correction circuit 21 (referred to as a PFC circuit), a bus capacitor Cbus, and a switching circuit 22 , a control circuit 62, a DC / DC isolation power module 61, an output capacitor Cout and an output load Rload.

[0068] The difference from the first embodiment is that the DC / DC isolated power module 61 includes two power modules 61a and 61b, the 61a and 61b do not contain an output voltage sampling unit, and the control and detection functions are implemented in the control circuit 62 . The two input terminals Vin1+ and Vin1- of the power module 61a are respectively connected to the first output terminal of the switching circuit and the second output terminal of the switching circuit, and the two input terminals Vin2+ and Vin2- of the power module 61b are respecti...

no. 3 example

[0073] Figure 8 Shown is the circuit schematic diagram of the third embodiment of the AC / DC power supply system of the present invention. The AC / DC power supply system includes an AC power supply, a power factor correction circuit 21, a bus capacitor Cbus, a control circuit 82, and a DC / DC isolation power supply. Module 81 and output capacitor Cout and output load Rload. The isolated power module 81 itself does not contain an output voltage sampling unit. The input terminal of the PFC circuit 21 is connected to the AC power supply, the positive output and the negative output of the PFC circuit are respectively connected to the positive input Vin+ and the negative input Vin- of the DC / DC isolated power module 81, and the positive output voltage of the PFC circuit is the bus voltage Vbus , the two ends of Cbus are respectively connected to the input Vin+ and Vin- of the DC / DC power circuit 81, the output terminals of the DC / DC isolated power module 81 are Vout+ and Vout-, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com