Roller state monitoring controller and control method

A control method and controller technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as difficult to analyze and improve the impact of the drum, and achieve the effect of improving the management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Aiming at the drum state monitoring controller and control method, a description of the working method of the system is given.

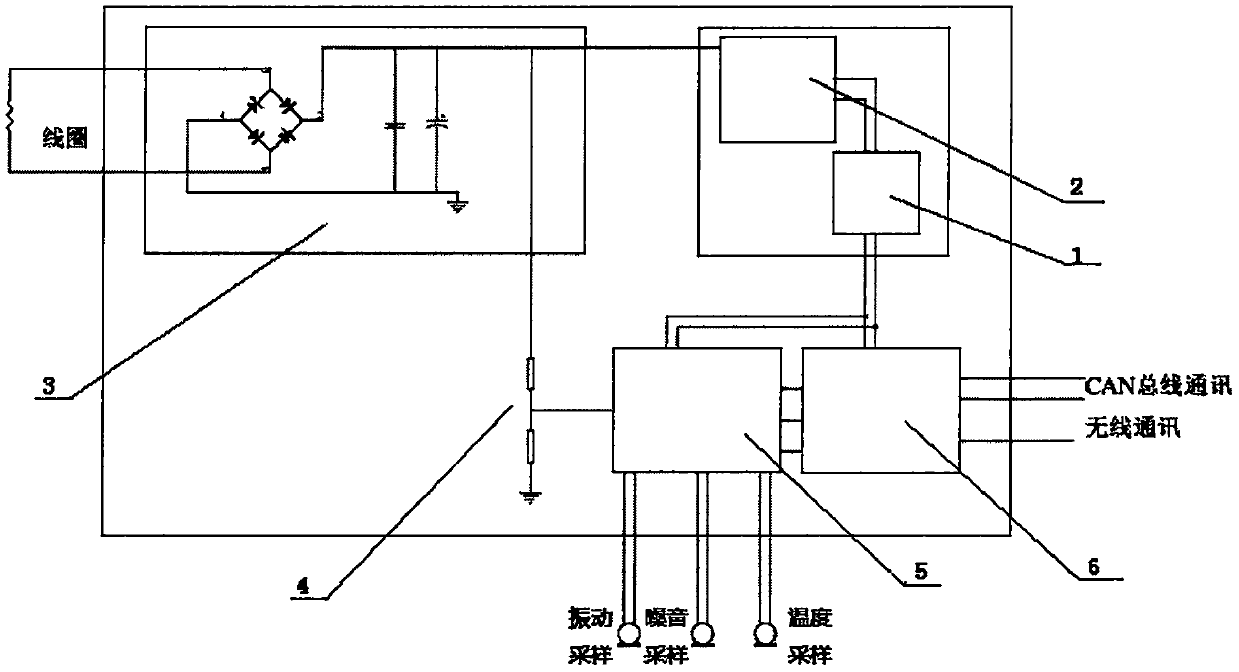

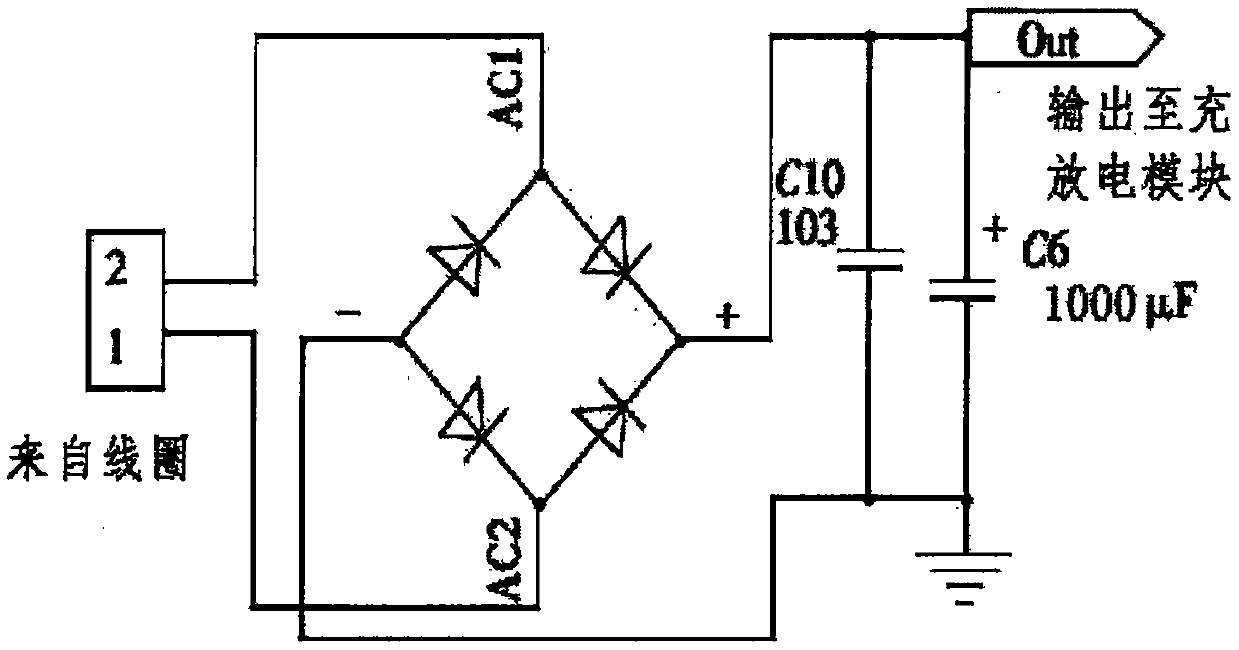

[0016] figure 1 Shown is the circuit structure diagram of the drum state monitoring controller and control method of the present invention. When the drum rotates, a voltage is induced inside the drum to charge the battery 1. The speed of the drum can be detected in real time through the voltage / speed sampling circuit 4. By The single-chip microcomputer module 5 updates the speed byte in the communication data in real time; by integrating the input speed signal to time, the actual running number of revolutions of the drum can be calculated, and the speed byte in the communication data is updated in real time through the single-chip microcomputer module 5 .

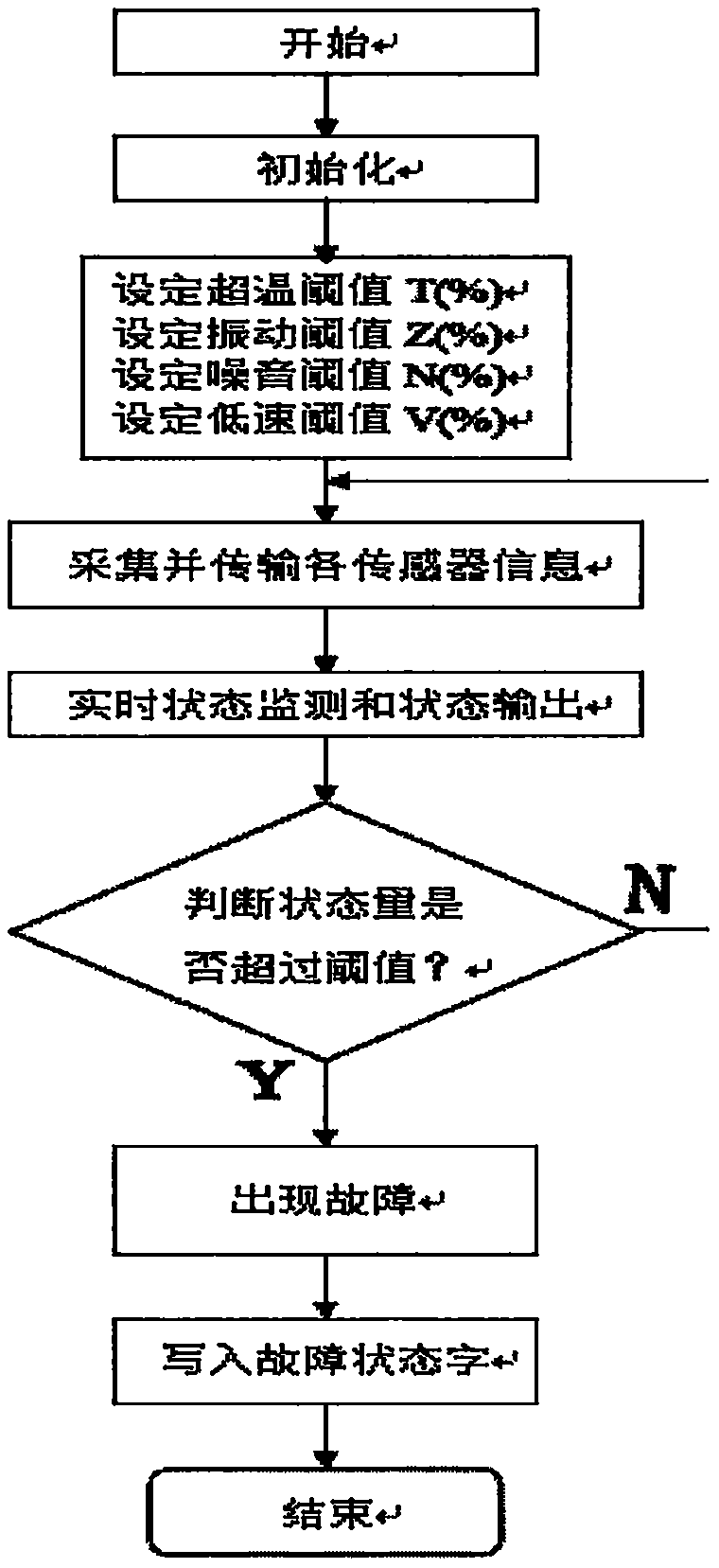

[0017] figure 2 Shown is the work flow chart of the drum state monitoring controller and control method of the present invention. The control method is as follows:

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com