Method for online monitoring of sulfur dioxide concentration in gas corrosion test box

A technology of gas corrosion and sulfur dioxide, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as difficulty in accurately controlling test time and test process, inability to guarantee the purity of corrosive gases, and deviations in actual concentrations , to achieve the effect of guaranteed reproducibility, small error and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

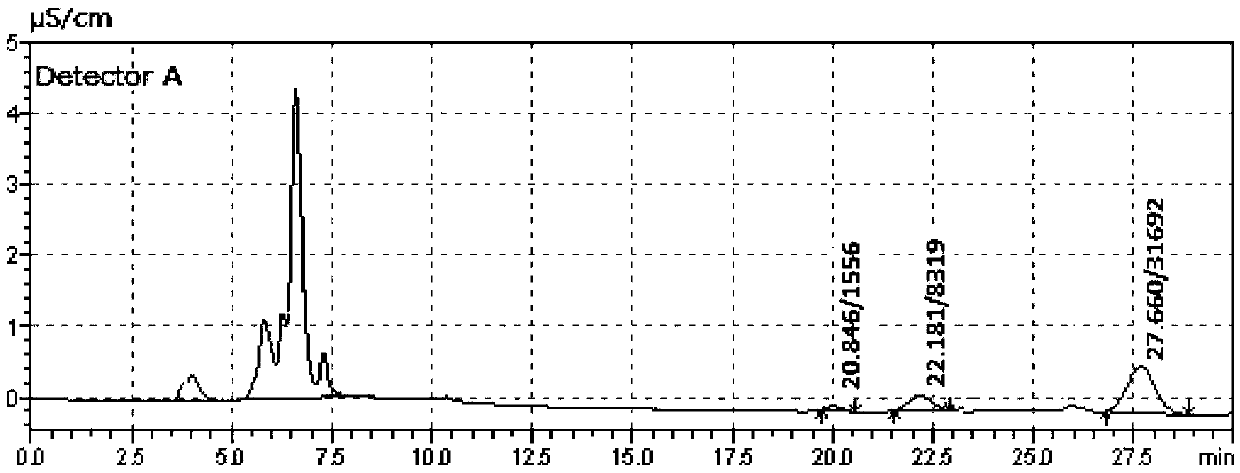

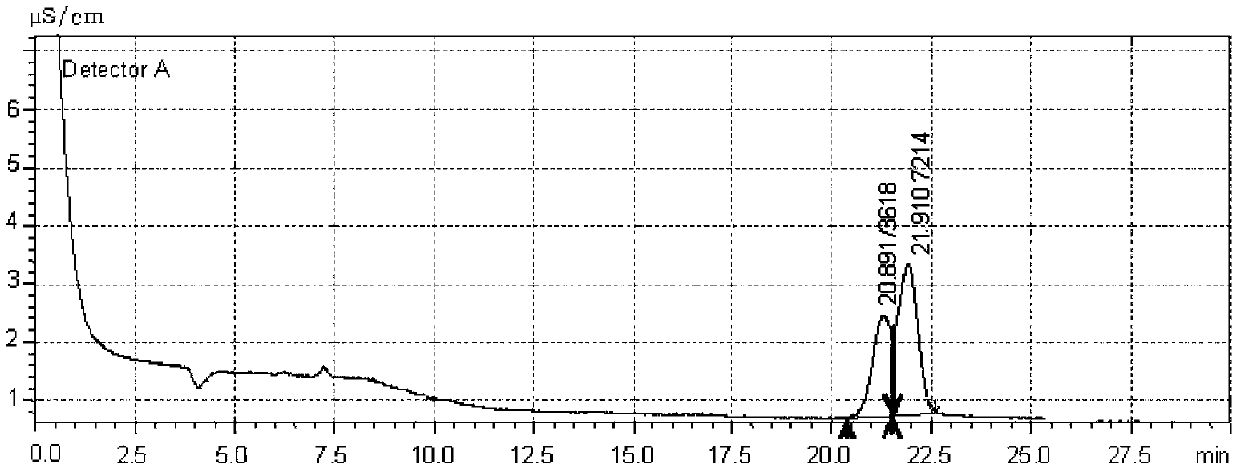

[0051] The method for on-line monitoring of sulfur dioxide concentration in a gas corrosion test chamber of the present invention comprises the following steps:

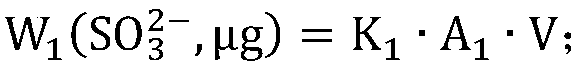

[0052] 1. Seal the volumetric flask containing 300mL of potassium carbonate absorption solution with a concentration of 0.1mmol / L with a rubber stopper to make an absorption bottle. The volume of the volumetric flask is 500mL, and connect it to the gas outlet and gas purification of the gas corrosion test chamber with a rubber tube between devices. After 30 minutes of absorption, remove the absorption bottle and replace it with a new absorption bottle. The absorption liquid in the absorption bottle can also be taken in the range of 300-1000 ml, and the absorption bottle should be replaced every 0.5-1 hour. Each time the absorption bottle is replaced, a newly prepared equal amount of absorption liquid is added to the bottle. K 2 CO 3 The concentration of the aqueous solution can also be 1×10 -2 Within the range of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com