Water vapor shunt type cooling tower filler

A cooling tower and split-flow technology, which is applied in the field of cooling towers, can solve the problems of inconvenient maintenance, increased air resistance, air heat exchange and troublesome process, etc., and achieve the effects of reducing maintenance costs, improving heat exchange efficiency, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing, set forth more details in the following description so as to fully understand the present invention, but the present invention can be implemented in many other modes different from this description obviously, Those skilled in the art can make similar promotions and deductions based on actual application situations without violating the connotation of the present invention, so the content of this specific embodiment should not limit the protection scope of the present invention.

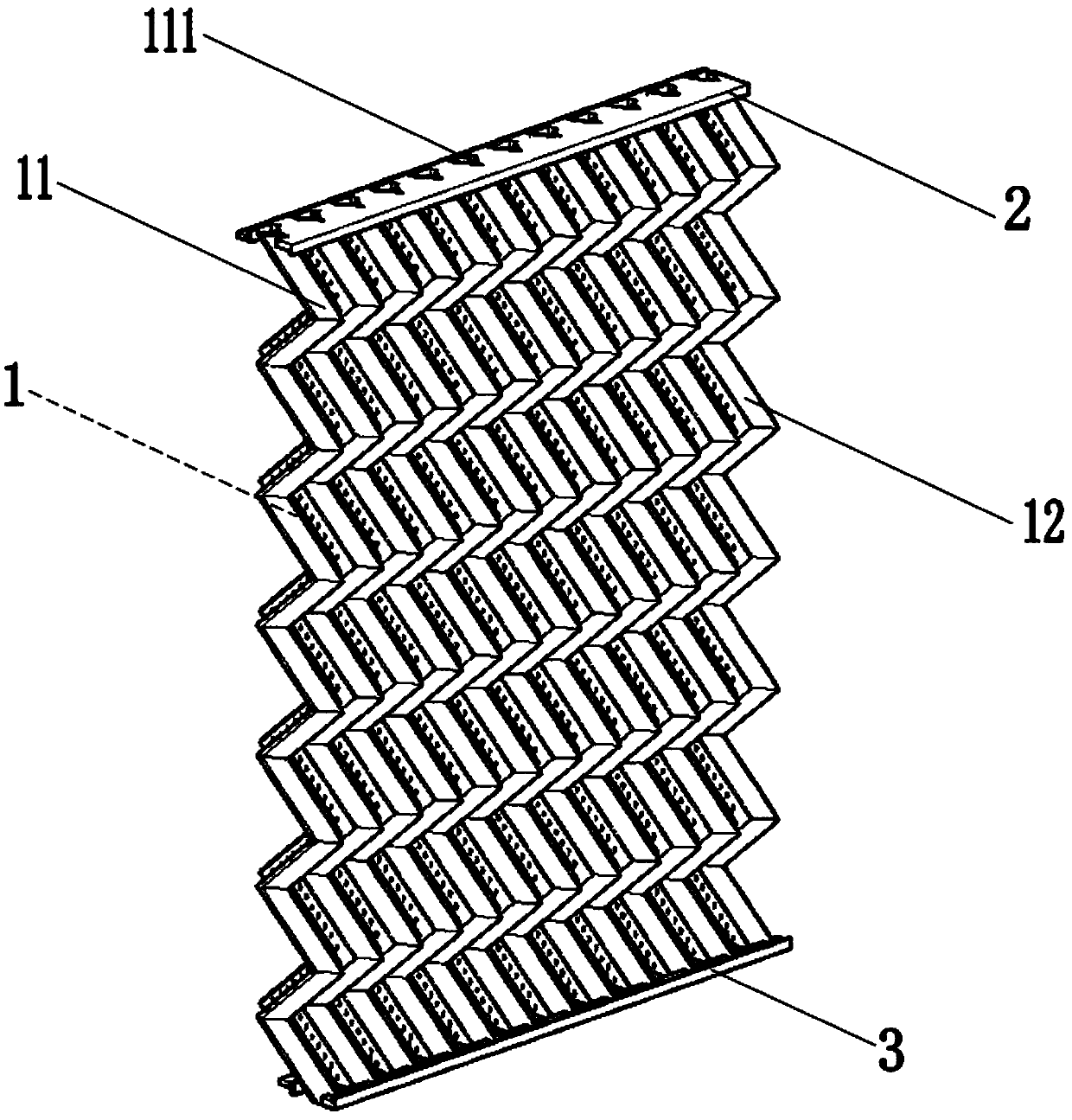

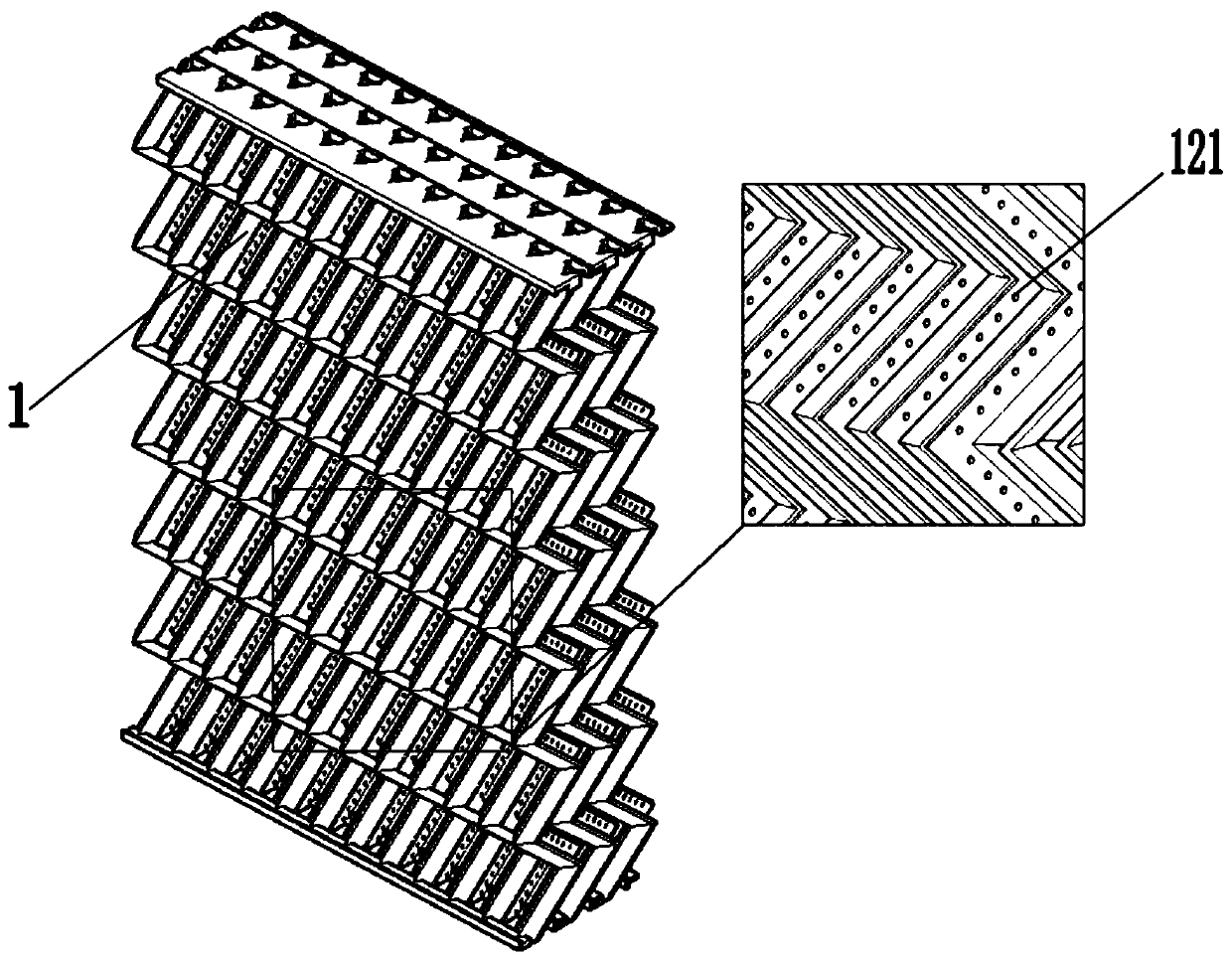

[0032] Such as figure 1 As shown, a water-air split cooling tower packing includes: sheet packing 1, chute block 2, chute 3;

[0033] The sheet-like filler 1 is stacked horizontally to form the filler required for the entire cooling tower;

[0034] Such as figure 1 As shown, the sheet packing 1 includes: a running water plate 11, an air intake channel 12;

[0035] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com