Multistage gas reverse swirl burner

A swirl burner, gas technology, applied in burners, burners for burning powder fuel, combustion methods, etc., can solve the problems of low fuel energy utilization, reduce energy waste, insufficient combustion, etc., and improve stability. , High thermal efficiency, easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below through specific embodiments.

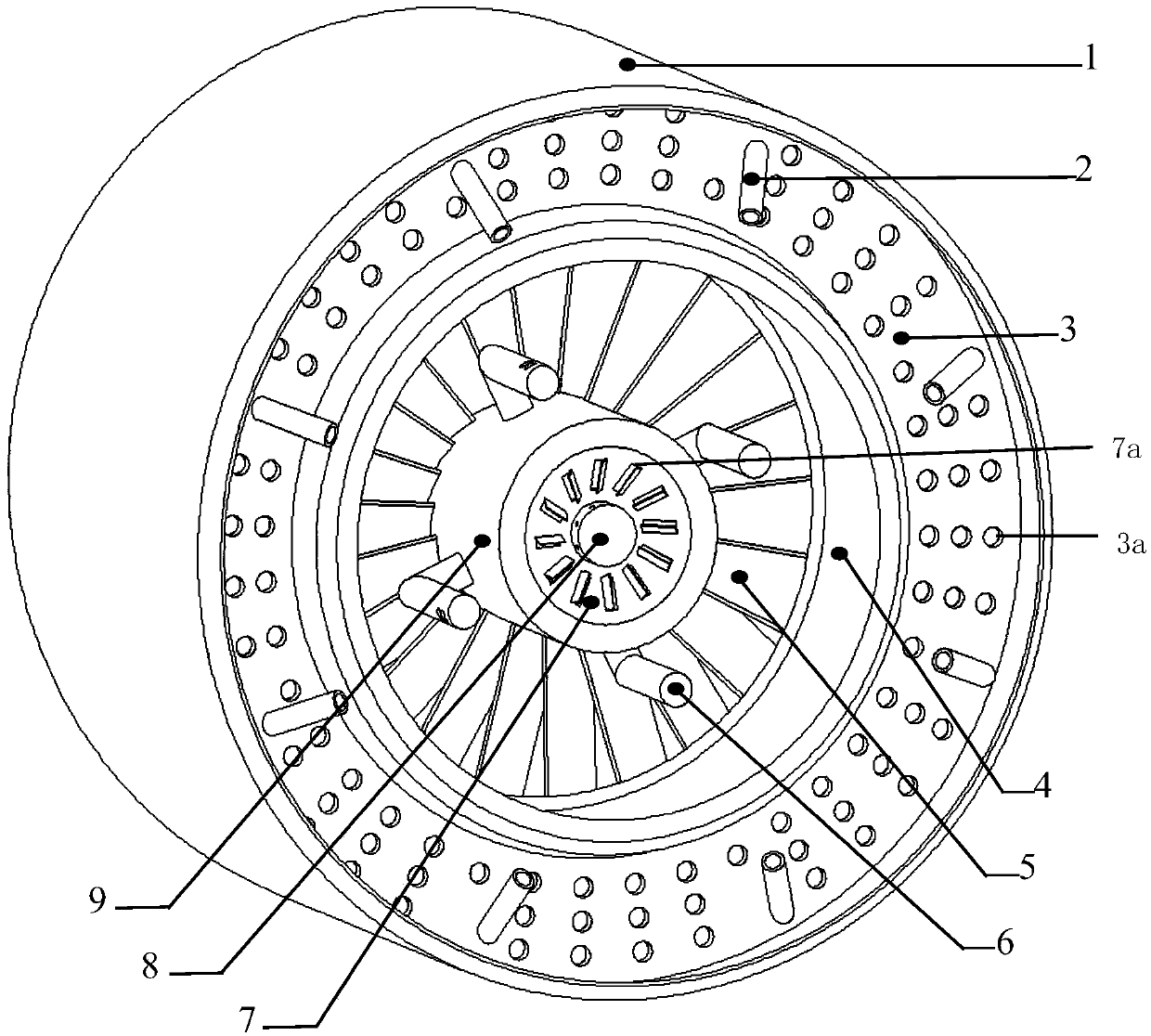

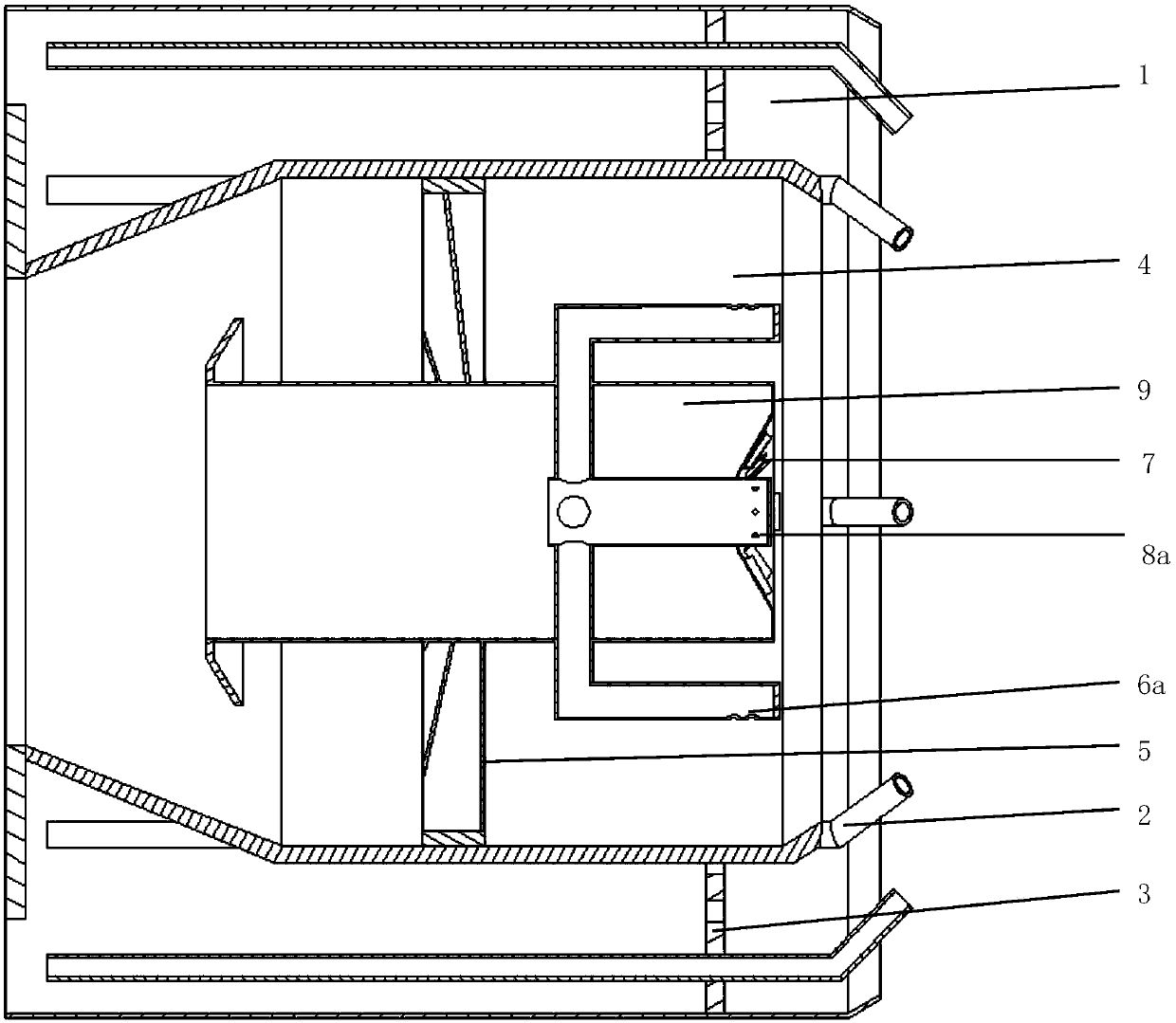

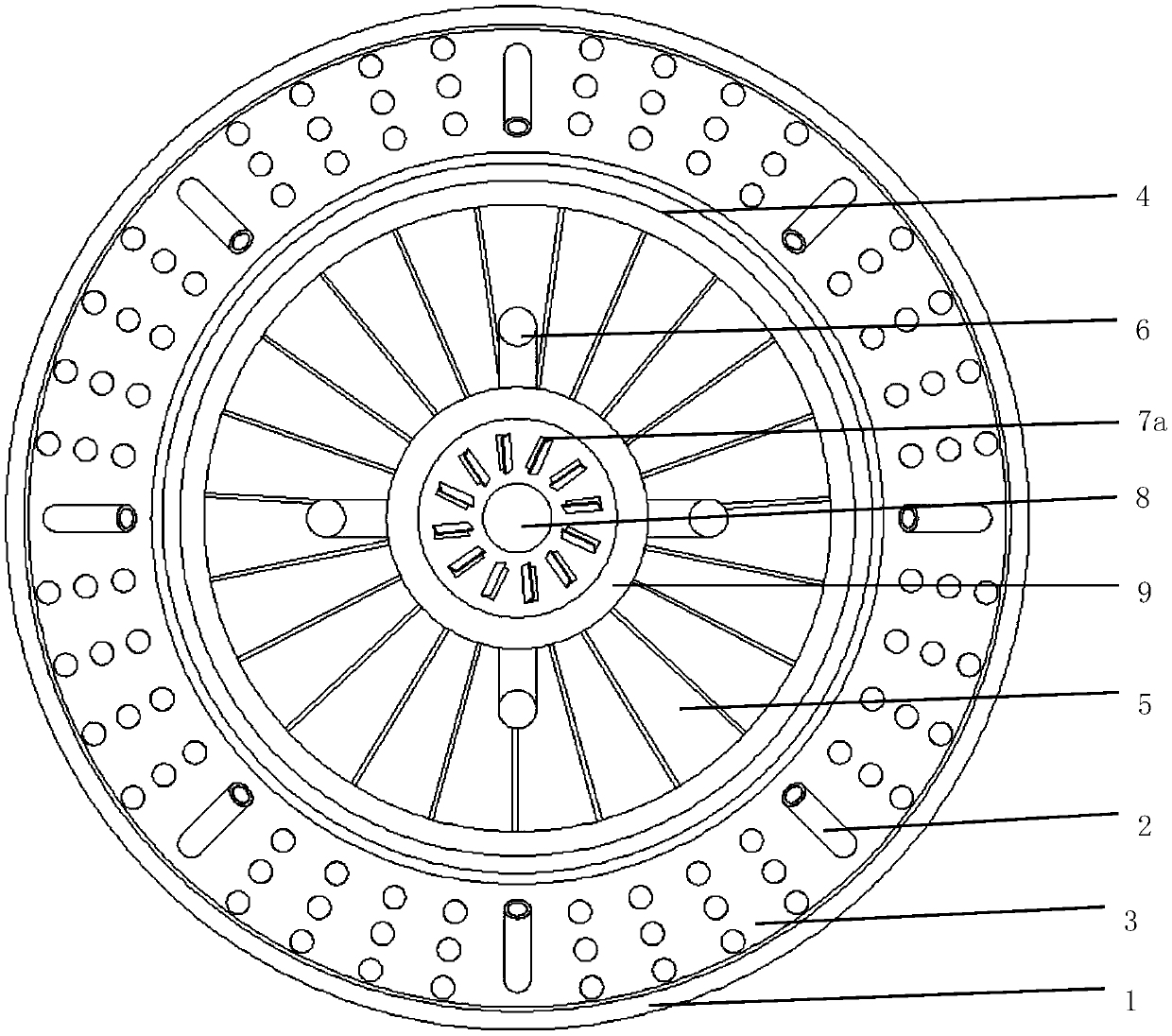

[0031] see Figure 1 to Figure 4 , a multi-stage gas reverse swirling burner, including a fuel nozzle group and an air guide barrel group, etc., the air guide barrel group includes a first-stage air guide barrel 9, a second-stage air guide barrel 4 and a third-stage air guide barrel 1. The air inlet end of the first-stage air guiding barrel 9 is provided with a variable diameter section, which is similar to a cone, and its inner diameter gradually increases or decreases along the air inlet direction. The air outlet end of the first-stage air guide bucket 9 is provided with a flame-stabilizing disc 7, which is conical and is provided with through holes and a plurality of first blades 7a, and the through-holes are located in the middle of the flame-stabilizing disc 7 for fuel nozzles. Pass through, the first vane 7a is distributed along the circumference of the through hole, and the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com