High-pressure dynamic sealing structure applicable to gearbox

A dynamic seal structure and gear box technology, applied in the direction of engine seals, belts/chains/gears, engine components, etc., can solve problems such as seal failure and decrease in axial pressure bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

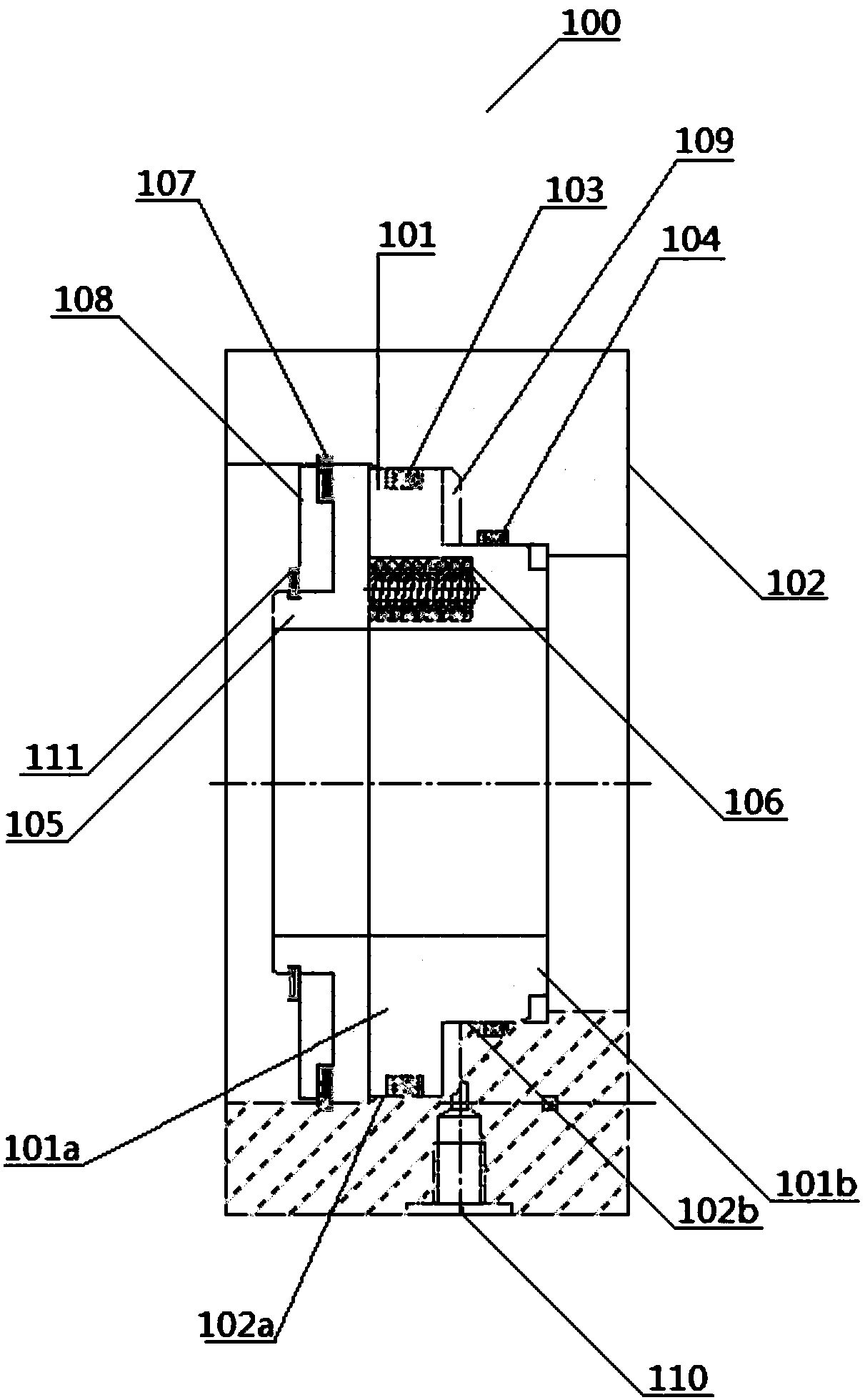

[0024] As a specific implementation manner, the combined sealing ring 103 for holes includes: a star-shaped sealing ring for holes and two sealing baffles for holes. The shaft combined sealing ring 104 includes: a shaft star-shaped sealing ring and two shaft sealing baffles. More specifically, the bore sealing star is positioned between two bore sealing baffles. The shaft star seal is located between the two shaft seal baffles.

[0025] Star rings for bores have lower friction than O-rings, reducing the risk of distortion. The two hole sealing baffles clamp the hole star-shaped sealing ring from both sides, thereby reducing the risk that the hole combined sealing ring 103 is squeezed into the gap between the piston 101 and the cylinder body 102 .

[0026] Star rings for shafts have lower friction than O-rings, reducing the risk of deformation or twisting. The two shaft seal baffles clamp the shaft star seal ring from both sides to reduce the risk of the shaft combined seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com