Miniature ball screw integrated bearing assembly

A ball screw and bearing technology, applied in bearing components, shafts and bearings, belts/chains/gears, etc., can solve problems such as noise and steel ball collision, reduce noise, improve service life and accuracy, and improve fluency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

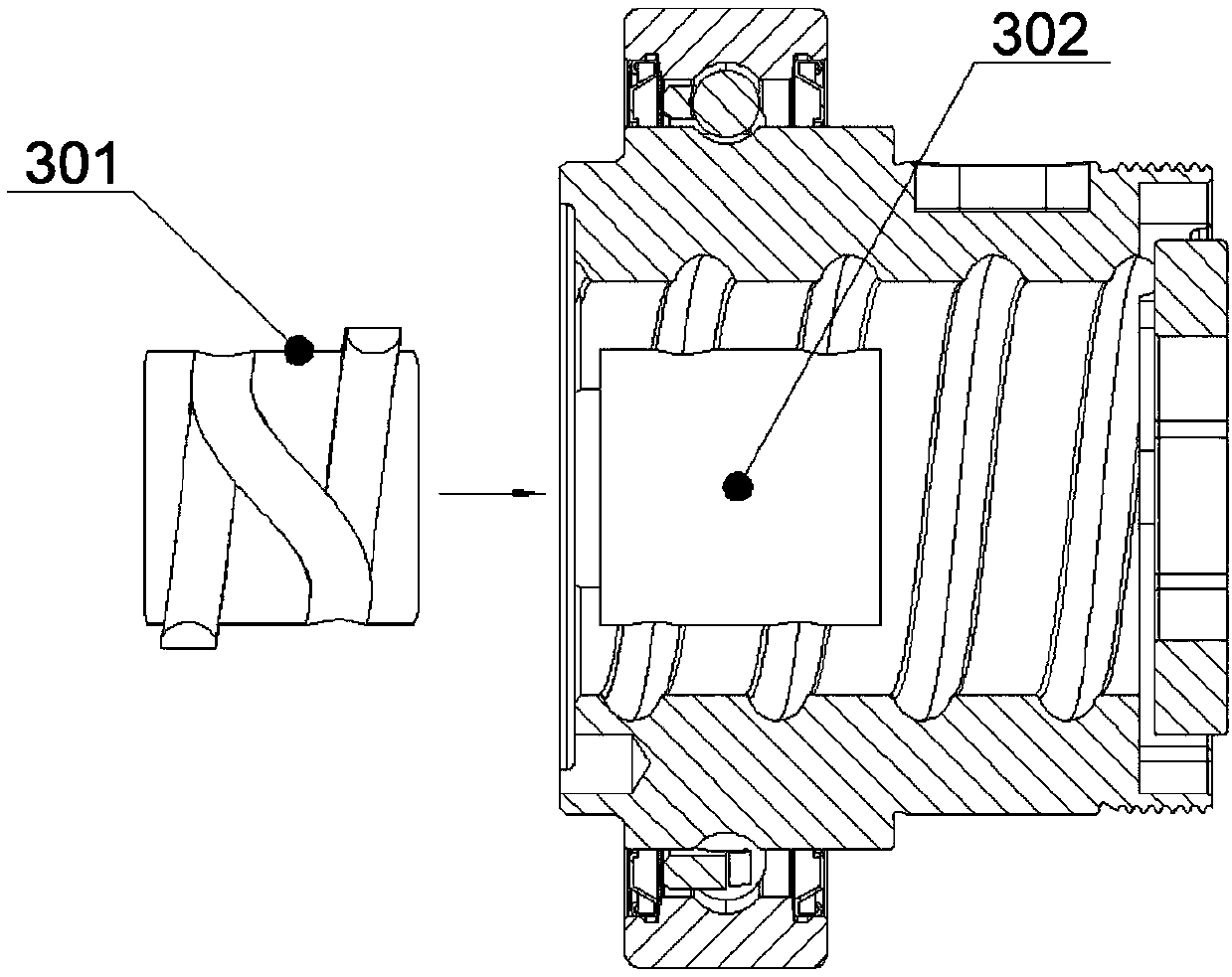

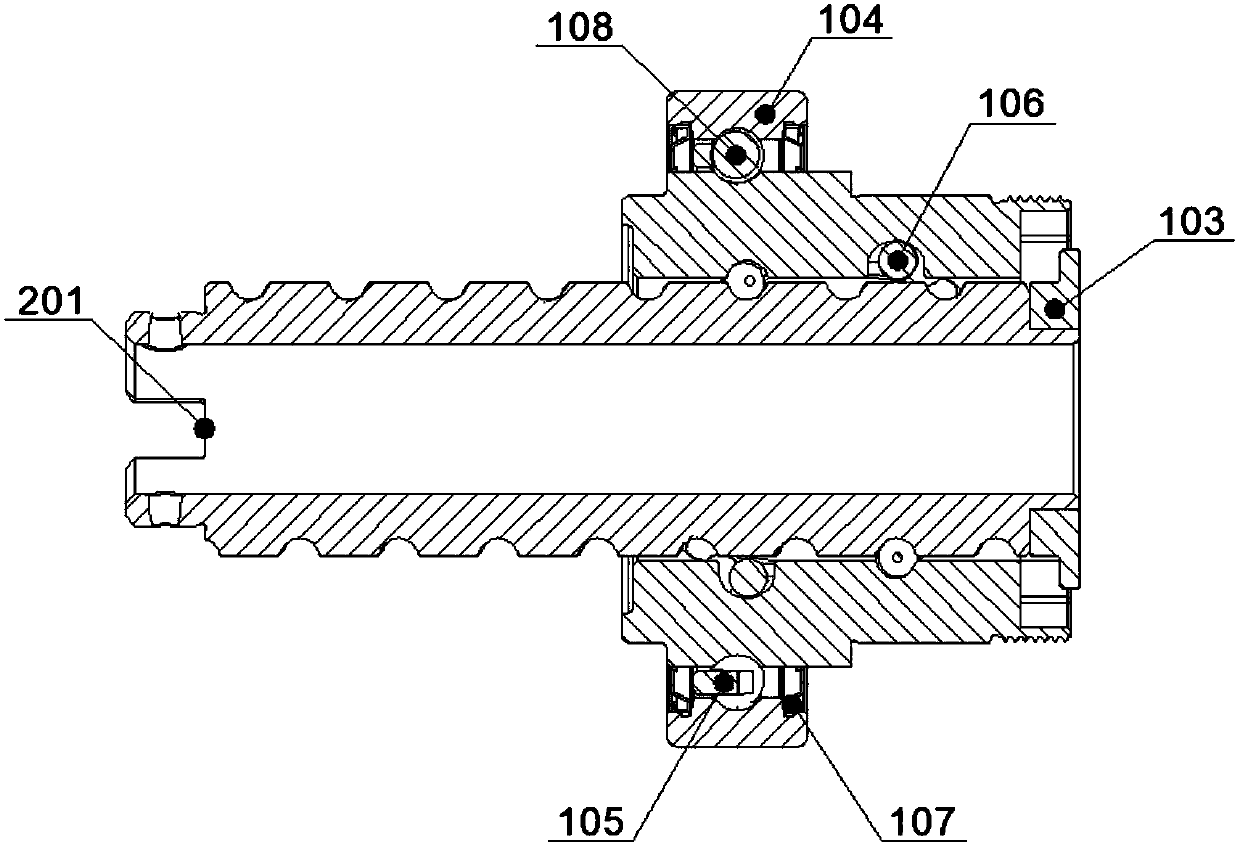

[0030] Combine below Figure 2 to Figure 6 , the present invention is further described:

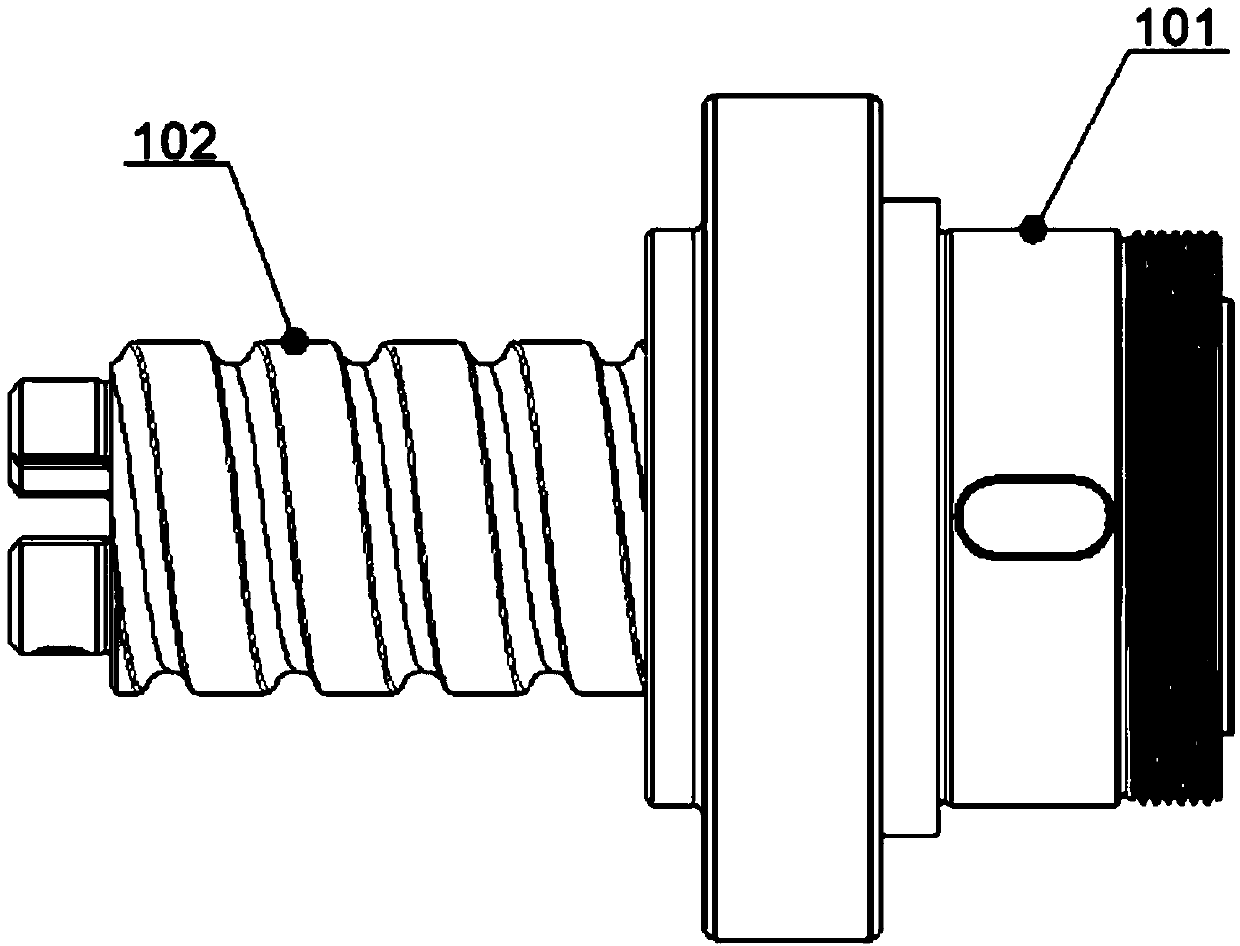

[0031] Such as Figure 2-Figure 4 As shown, a miniature ball screw integrated bearing assembly includes a nut 101 and a screw 102. Between the nut 101 and the screw 102, the ball 106 of the screw is used as a rolling body to convert the rotational motion of the nut 101 into a screw. Linear motion of the bar 102. Also includes a bearing, the bearing includes a bearing outer ring 104 and a bearing inner ring, a bearing steel ball 108 and a sealing ring 107 are arranged between the bearing outer ring 104 and the bearing inner ring, and the bearing steel ball 108 is fixed on the bearing outer ring 104 by a cage 105 and the inner ring of the bearing. The bearing inner ring and the screw nut 101 are integrated into one piece. The inner ring of the above-mentioned bearing is integrated with the screw nut. Compared with the prior art bearing interference fit and pressing into the screw nut, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com