Initial launching tunnel door capable of being fast exploded in shield method connection passage construction

A communication channel and construction technology, which is applied in the field of shield tunneling communication channel construction, can solve the problem that the shield machine cannot greatly improve the efficiency of cutting the segment at the starting hole door, cannot meet the safety requirements, and affect the construction work efficiency, etc. It can reduce the amount of concrete residue, eliminate potential safety hazards and improve construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

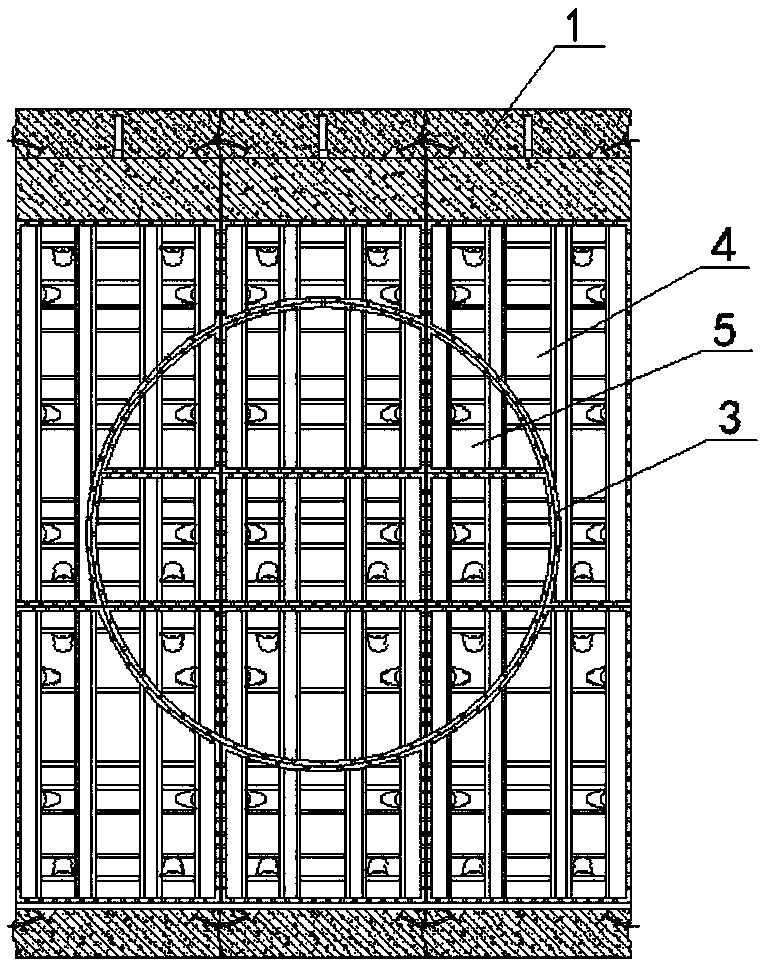

[0026] see Figure 5 , in this embodiment, a "T"-shaped interface is formed between the main tunnel 1 and the communication channel 2, and the starting portal 3 in the construction of the communication channel by the shield method is located at Figure 5 In the main tunnel on the "T" shaped interface shown.

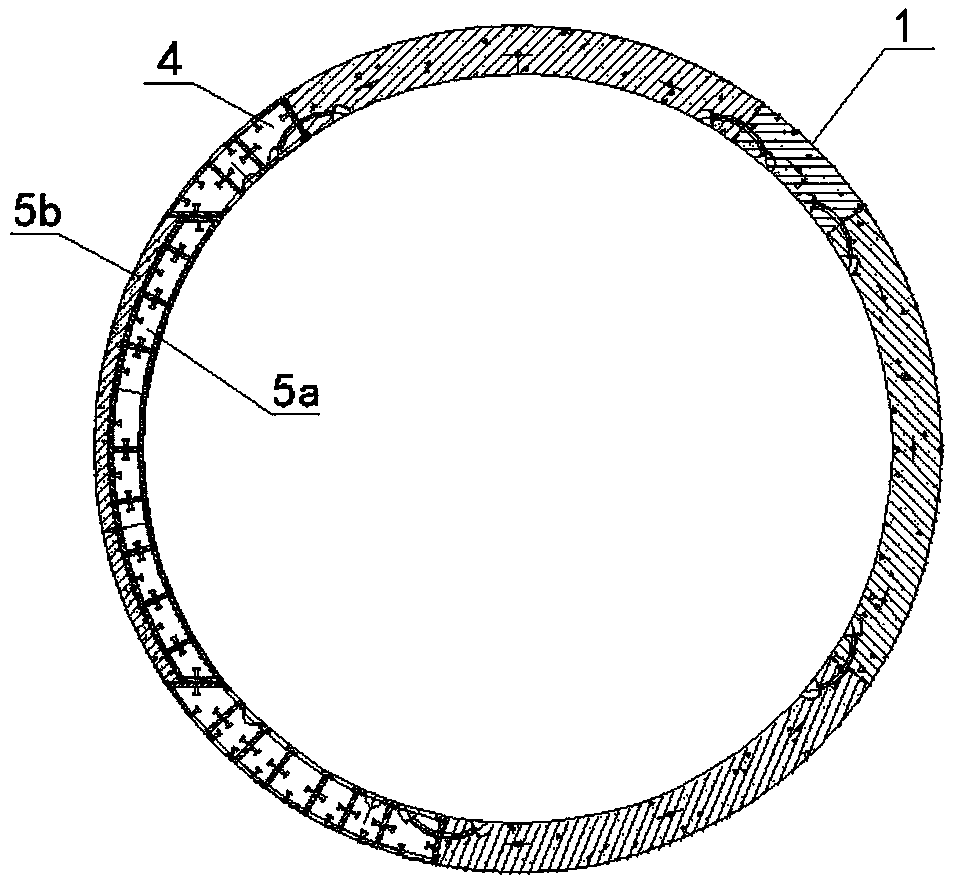

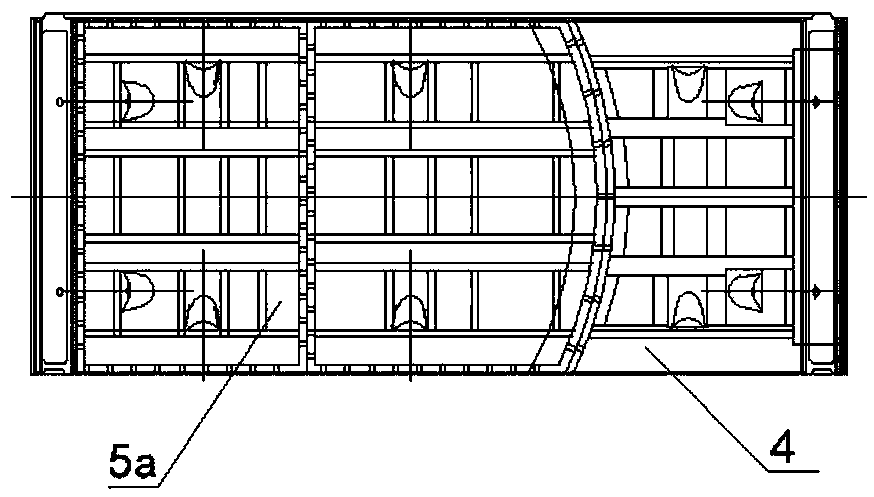

[0027] see figure 1 and figure 2 , the structural form of the originating portal that can be quickly broken in the construction of the shield method communication channel in this embodiment is: in the main tunnel 1, the opening segment of the originating portal 3 is an assembled segment, and the assembled segment The sheet is composed of the steel grid member 4 outside the opening and the composite layer member 5 inside the opening.

[0028] Such as figure 2 , image 3 and Figure 4 As shown, the steel grid member 4 around the opening has the same external shape and thickness as the main tunnel segment, and the opening space is reserved in the steel grid member 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com