Method for installing prefabricated line of external wall of fabricated structure PC member

An installation method and prefabricated technology, applied in the direction of building construction, construction, etc., can solve the problems of excessive damage, increased cost, and difficult quality control, and achieve the effect of less damage, reduced cost, and easy quality in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

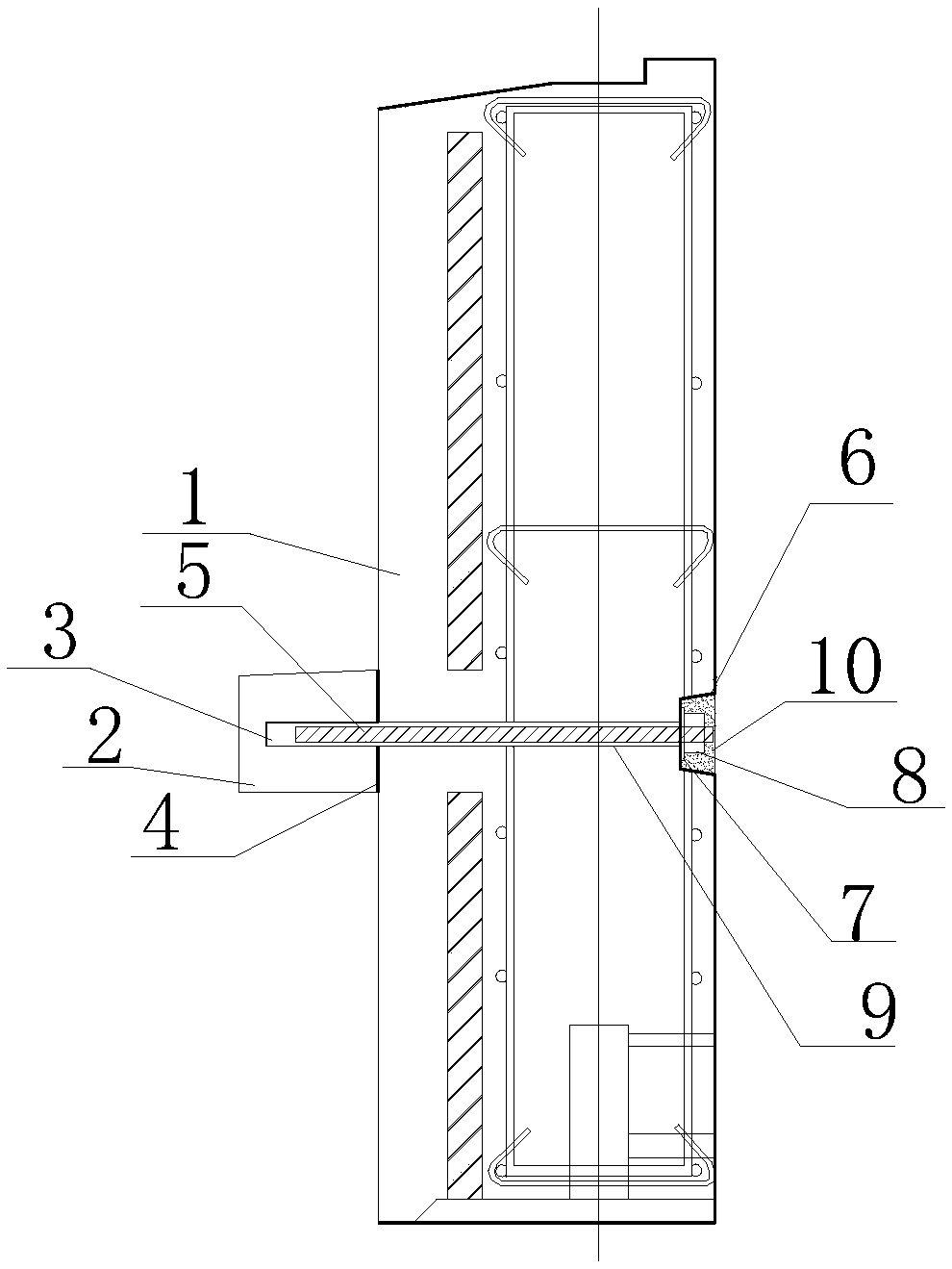

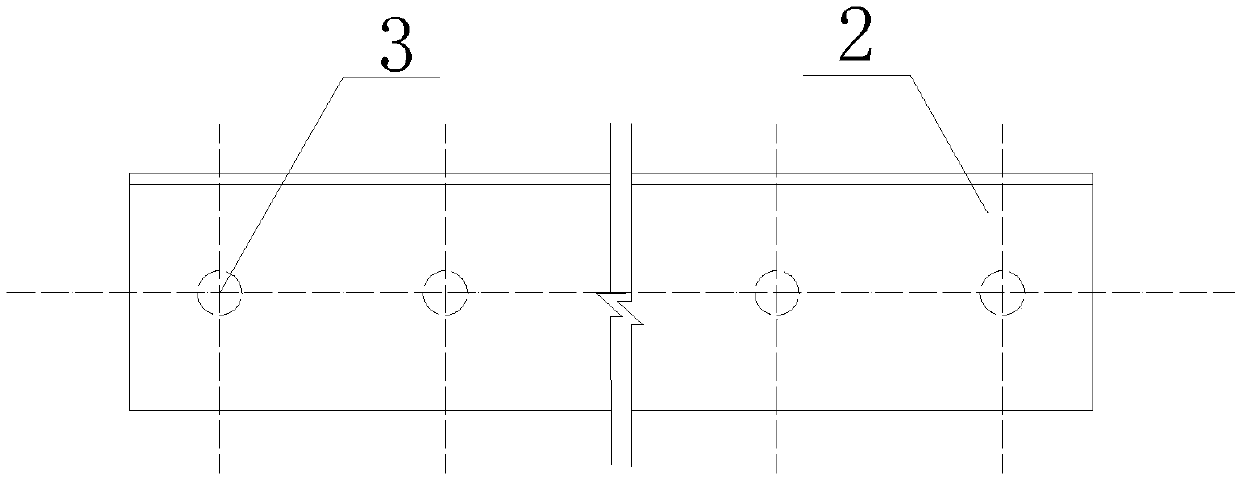

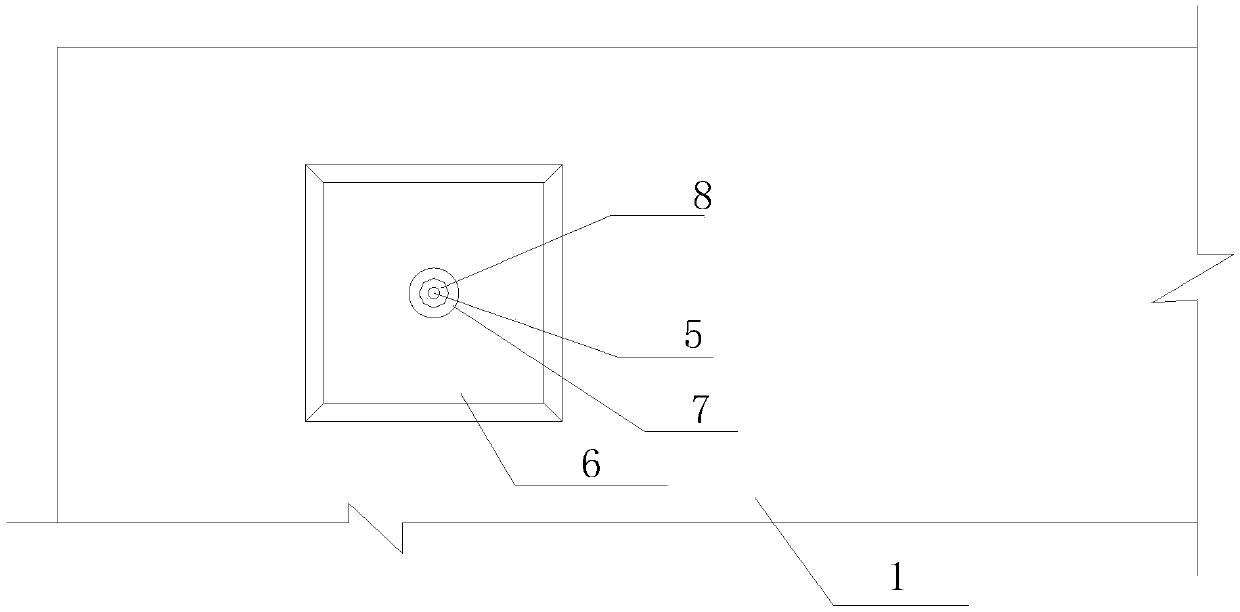

[0034] refer to Figure 1-3 , a method for installing prefabricated lines on the exterior wall of prefabricated PC components, comprising prefabricated lightweight concrete lines 2, prefabricated exterior wall PC components 1, reserved grooves 6 on the inner wall surface of the exterior wall PC components 1, and the grooves 6 The size is 70mm long, 70mm wide, and 30mm deep. The nut and gasket 7 are installed in the groove 6. After the screw rod 5 and the nut are installed, 1:2.5 waterproof mortar is used to seal 10; the outer wall The thickness of the PC component 1 is 290mm, the length of the prefabricated lightweight concrete line 2 is 120mm, the width is 105mm, and the height is 90mm, and the length of the sleeve 3 is 90mm; the following steps are also included:

[0035] A. Embed a sleeve 3 in the prefabricated lightweight concrete line 2, the diameter of the sleeve 3 is 16mm

[0036] B, prefabricated external wall PC member 1 pre-embeds plastic casing 9, and the diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com