High-strength and convenient -to-pour construction pile

A high-strength, construction pile technology, used in construction, sheet pile walls, infrastructure engineering, etc., can solve the problems of high labor intensity of workers, damage to the internal structure of the pile, and difficulty in sinking, so as to reduce the waiting time for solidification. , Improve the speed of construction and reduce the effect of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

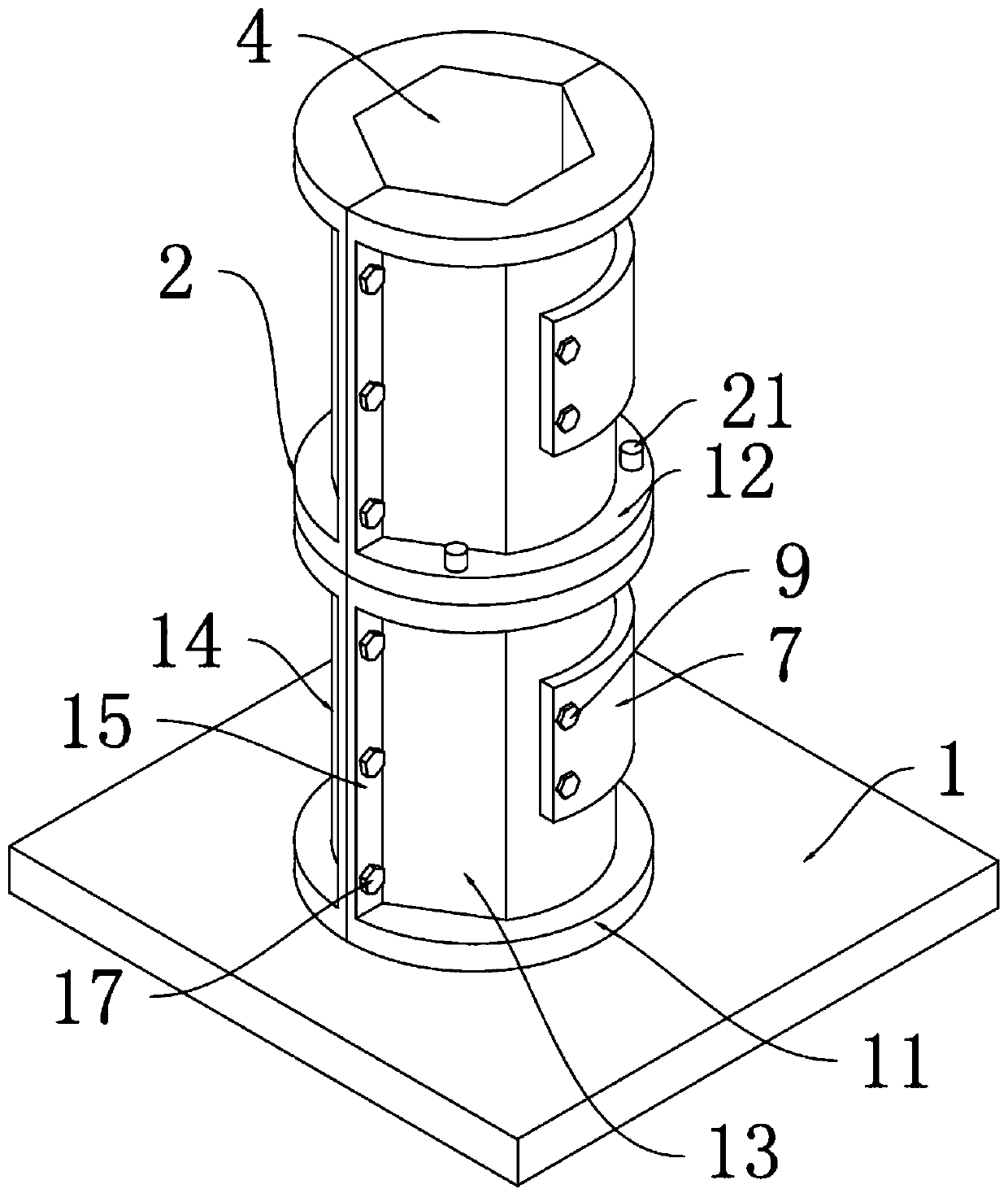

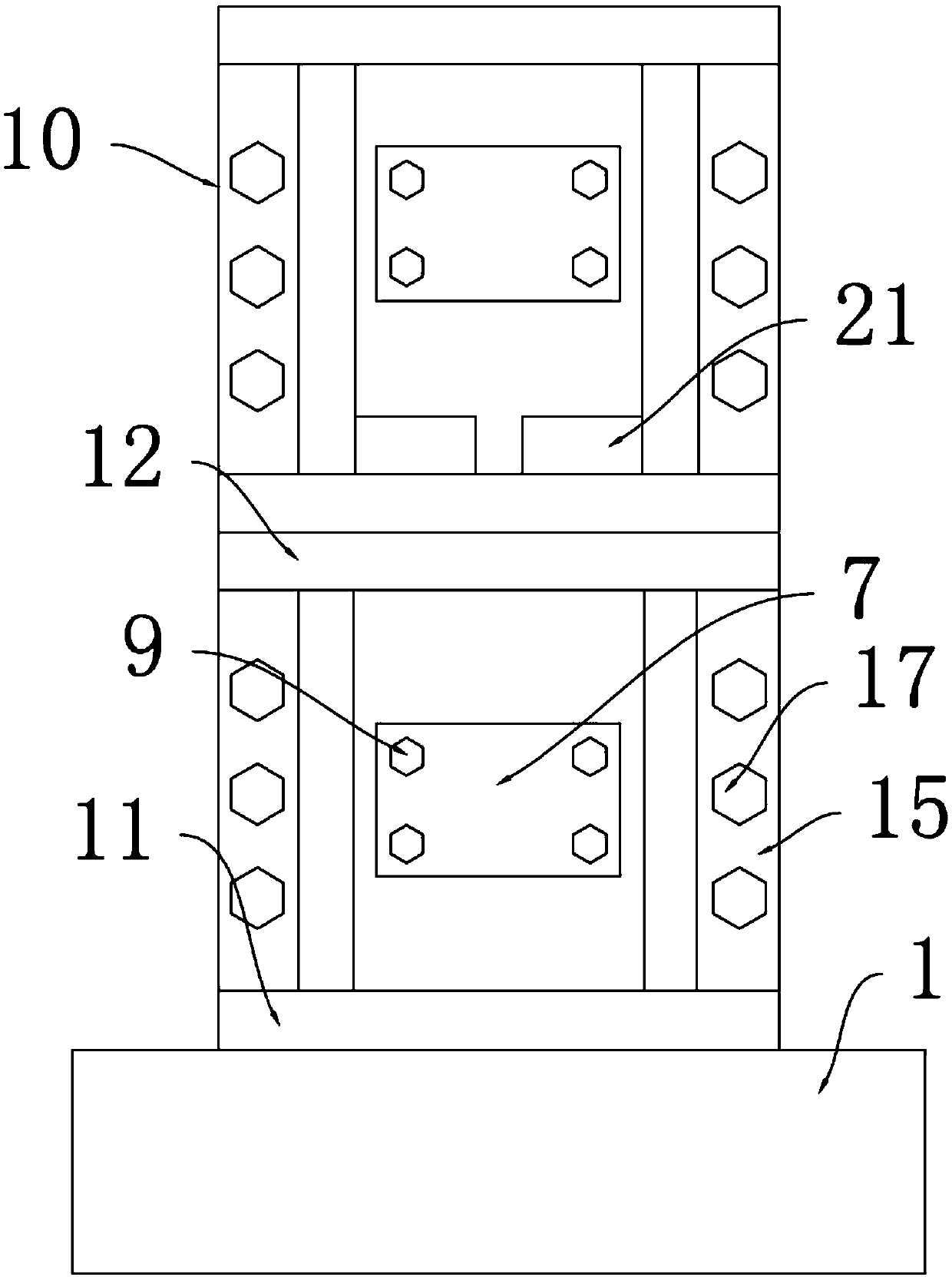

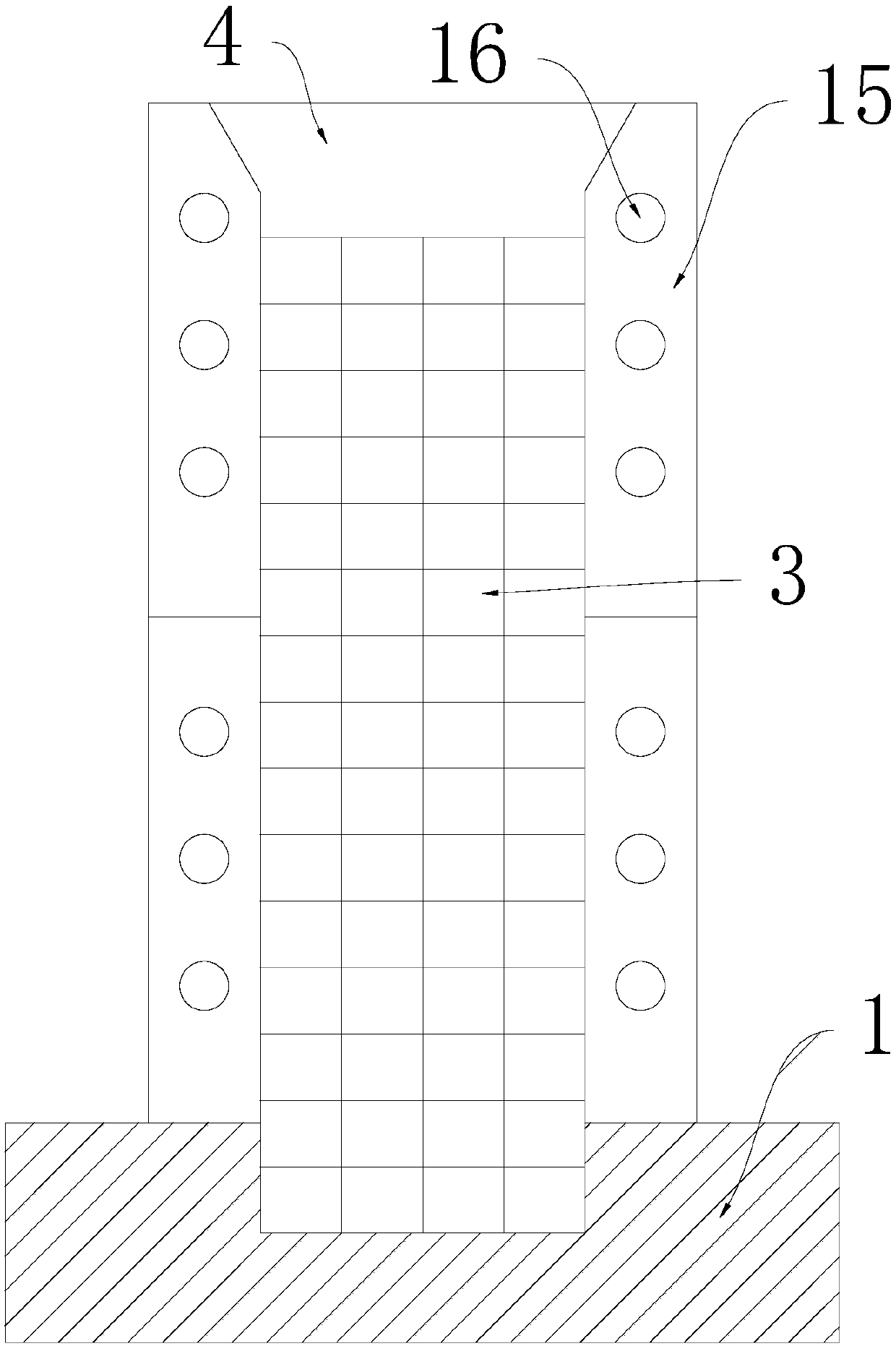

[0031] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a high-strength and easy-to-cast construction pile of the present invention includes a foundation 1 and a pile formwork 2, the bottom of the pile formwork 2 is fixedly connected to the top of the foundation 1, and the foundation located inside the pile formwork 2 The top of 1 is plugged with reinforcement cage 3.

[0032] The top of the pile body formwork 2 is provided with a concrete pouring opening 4, and the side of the pile body formwork 2 is provided with several ventilation holes 5, and the surface of the pile body formwork 2 on both sides of the ventilation hole 5 is provided with two threaded holes. 6. Several arc-shaped fixing plates 7 are arranged on the surface of the ventilation hole 5, and cylindrical holes 8 are opened at the four corners of the arc-shaped fixing plates 7, and first bolts 9 are interspersed in the cylindrical holes 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com