Loess high-fill furrow foundation drainage structure and laying method thereof

A technology of loess high filling and drainage structure, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of shortening the service life of blind ditch, subsidence of upper construction ground, and large-area subsidence of construction ground, etc., so as to be easy to popularize Use, use effect is good, effect of coarse particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

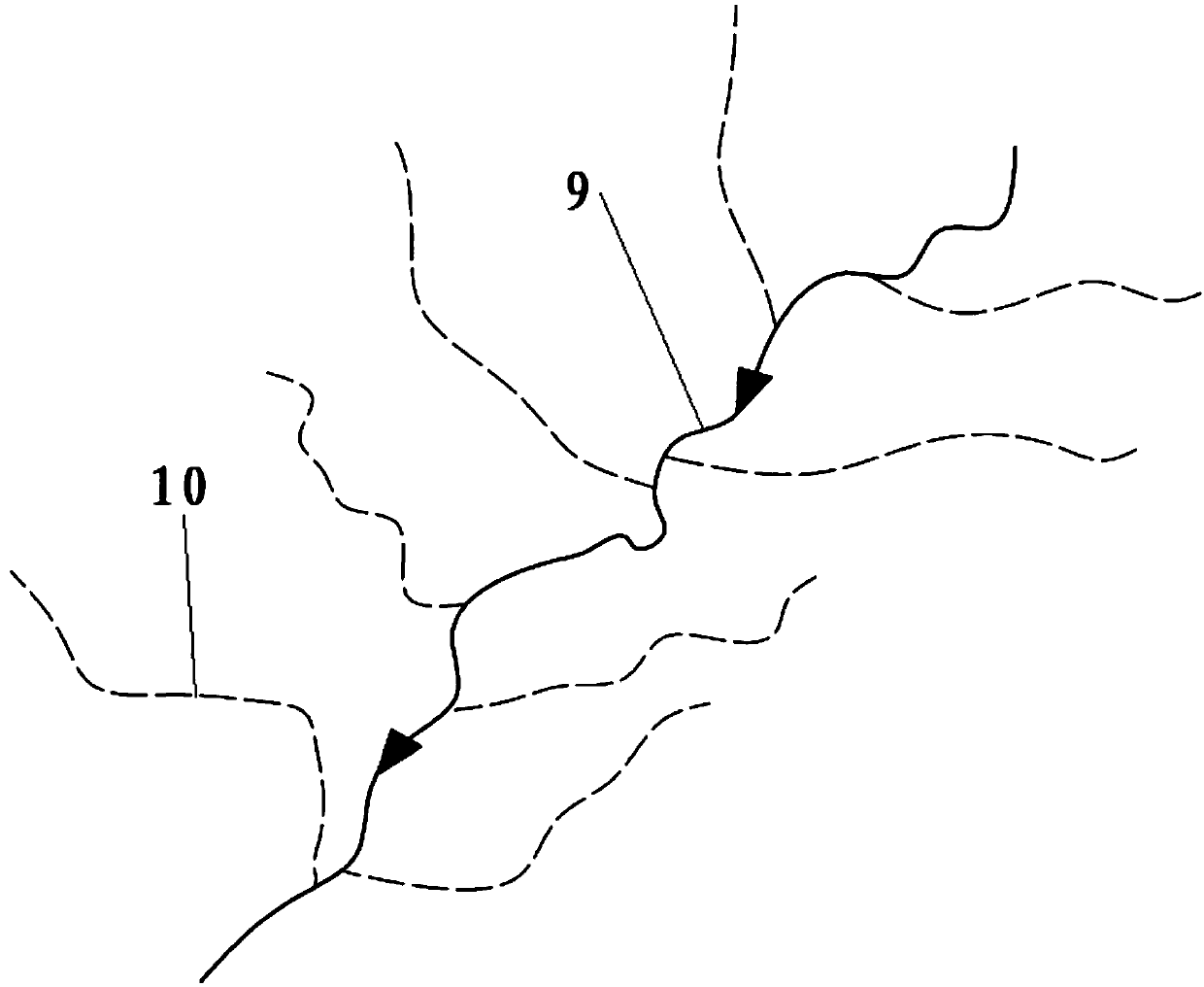

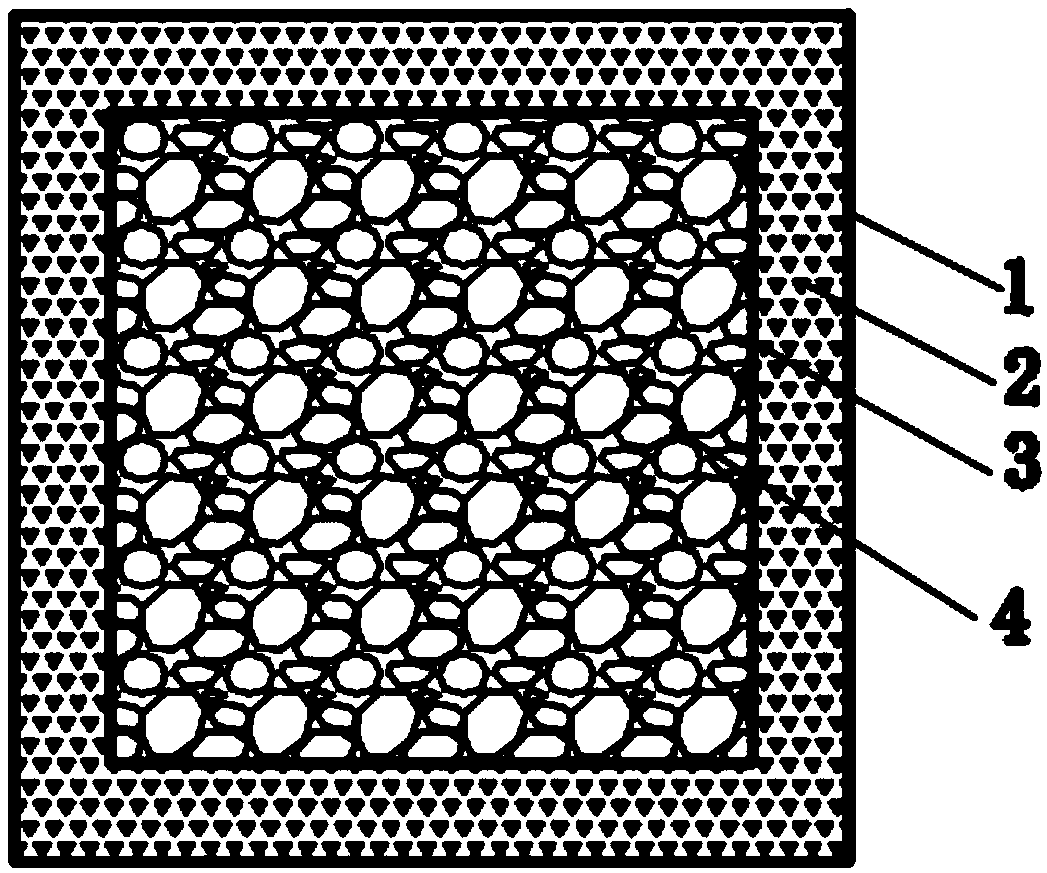

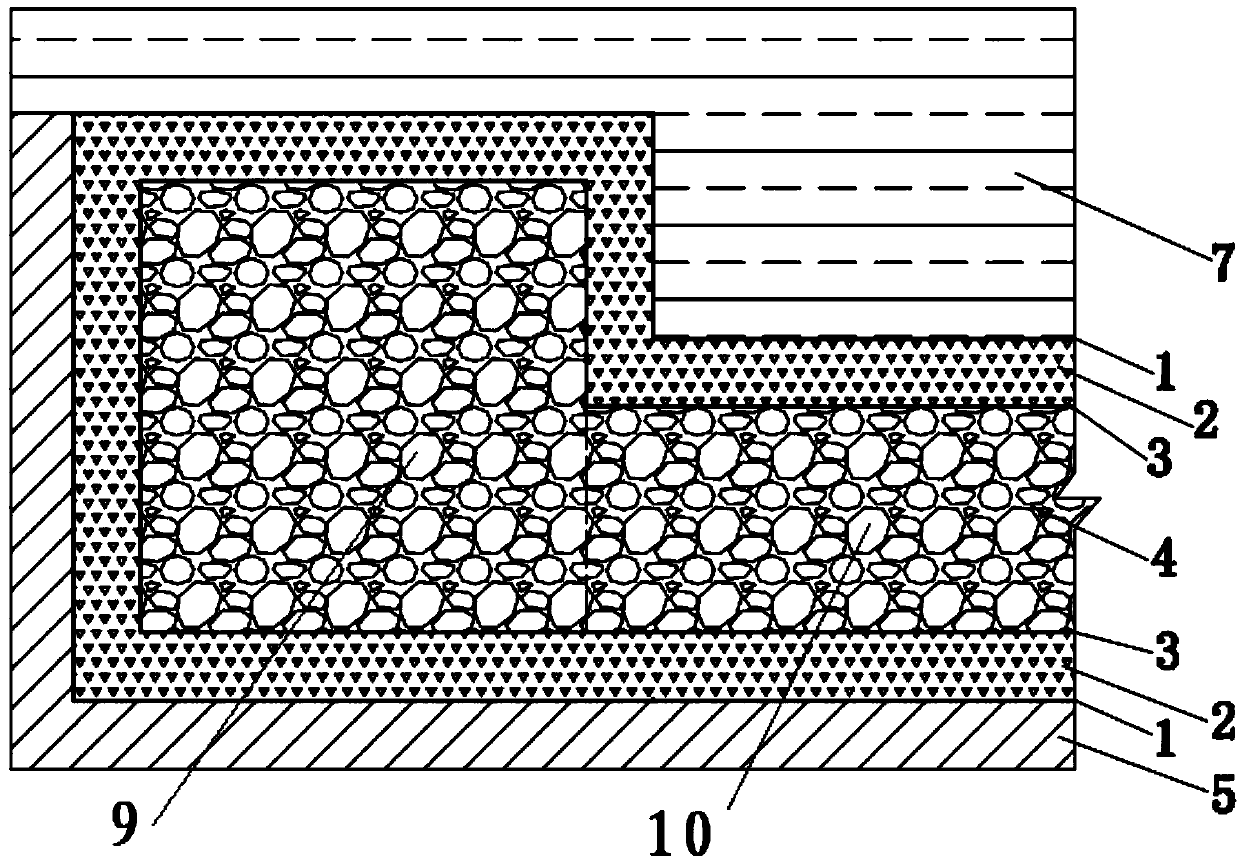

[0056] Such as Figure 1 to Figure 3 As shown, a kind of loess high-fill ditch foundation drainage structure according to the present invention includes the main blind ditch 9 laid on the original loess foundation 5 along the extension direction of the main ditch in the original ditch terrain and the extension direction of the branch ditch along the original ditch terrain. The secondary blind ditch 10 that is laid on the original loess foundation 5 and connected with the main blind ditch 9, the elevation of the base surface at the position where the secondary blind ditch 10 communicates with the main blind ditch 9 is equal to the elevation of the base surface of the main blind ditch 9 at this position, The secondary blind ditch 10 and the main blind ditch 9 both include an outer geotextile protective layer 1, an interlayer fine-grained gravel filter protection layer 2, an inner geotextile filter layer 3 and an inner core coarse-grained drainage layer laid sequentially from outs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com