Uniaxial mixing device of explosive materials

A technology of material mixing and explosives, which is applied in the direction of explosives composite components, explosives, explosives processing equipment, etc., can solve the problems of weakening material fluidity, single production quantity, and affecting mixing efficiency, so as to improve the safety and efficiency of mixing, The effect of high flow velocity and improved mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present application will be further described below in combination with the accompanying drawings and specific implementation methods.

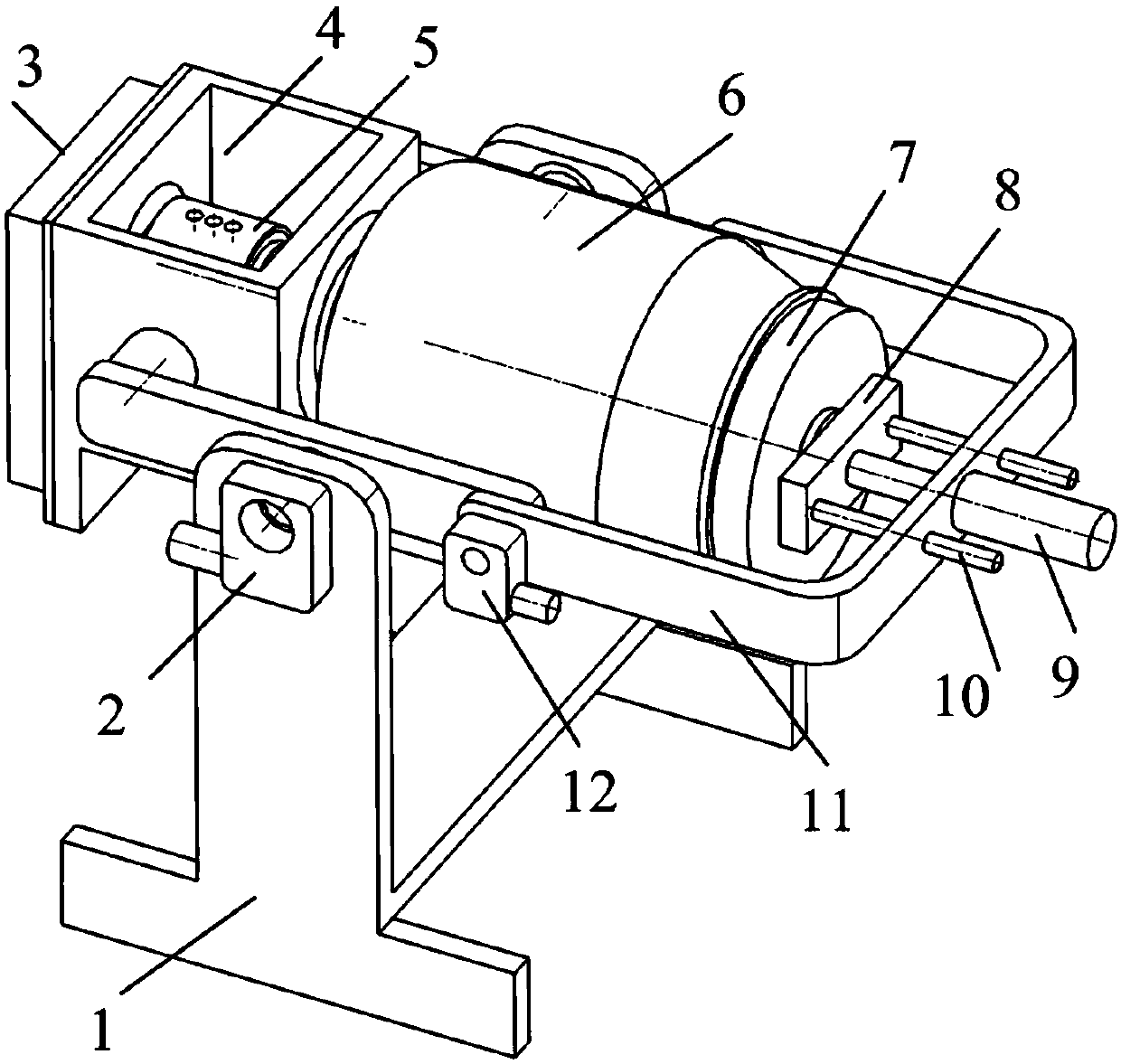

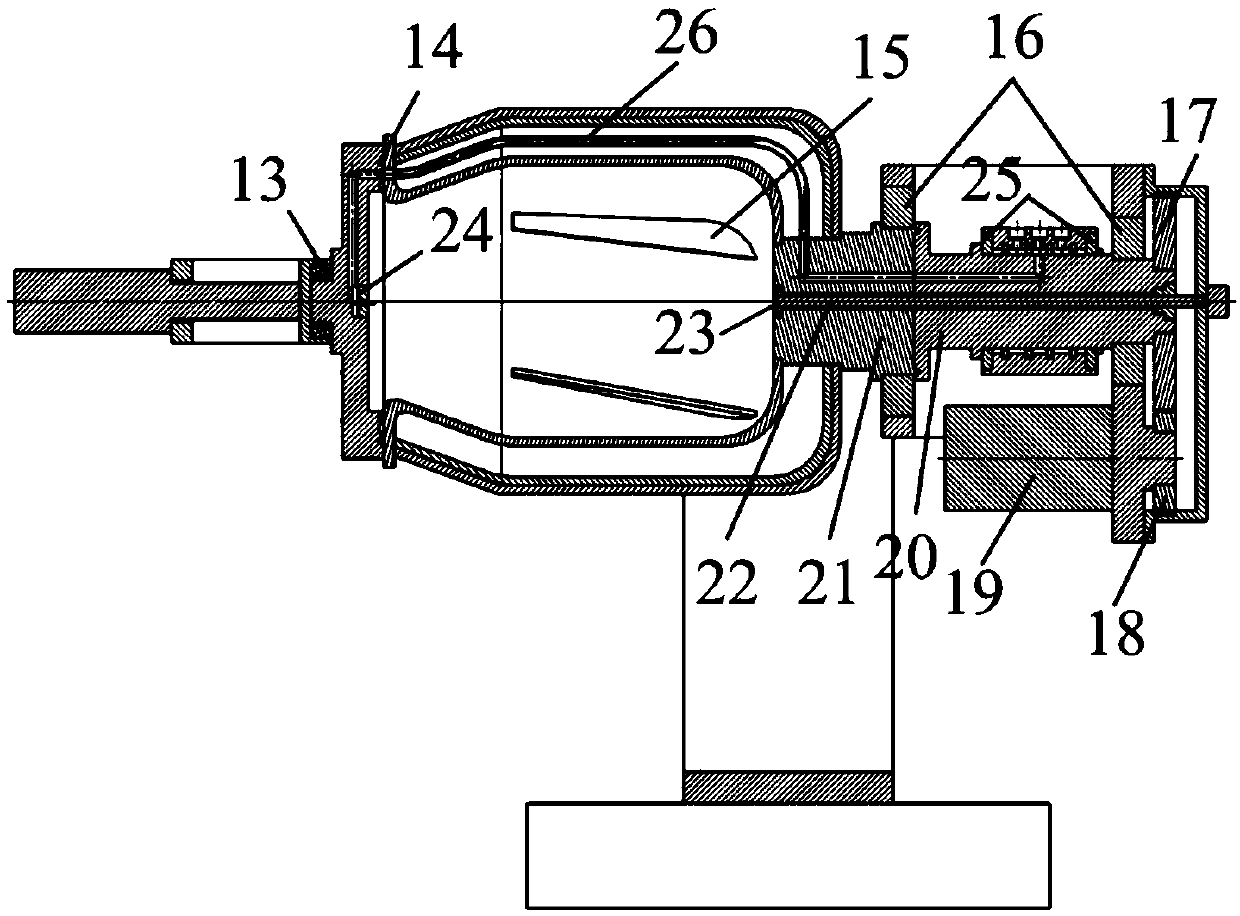

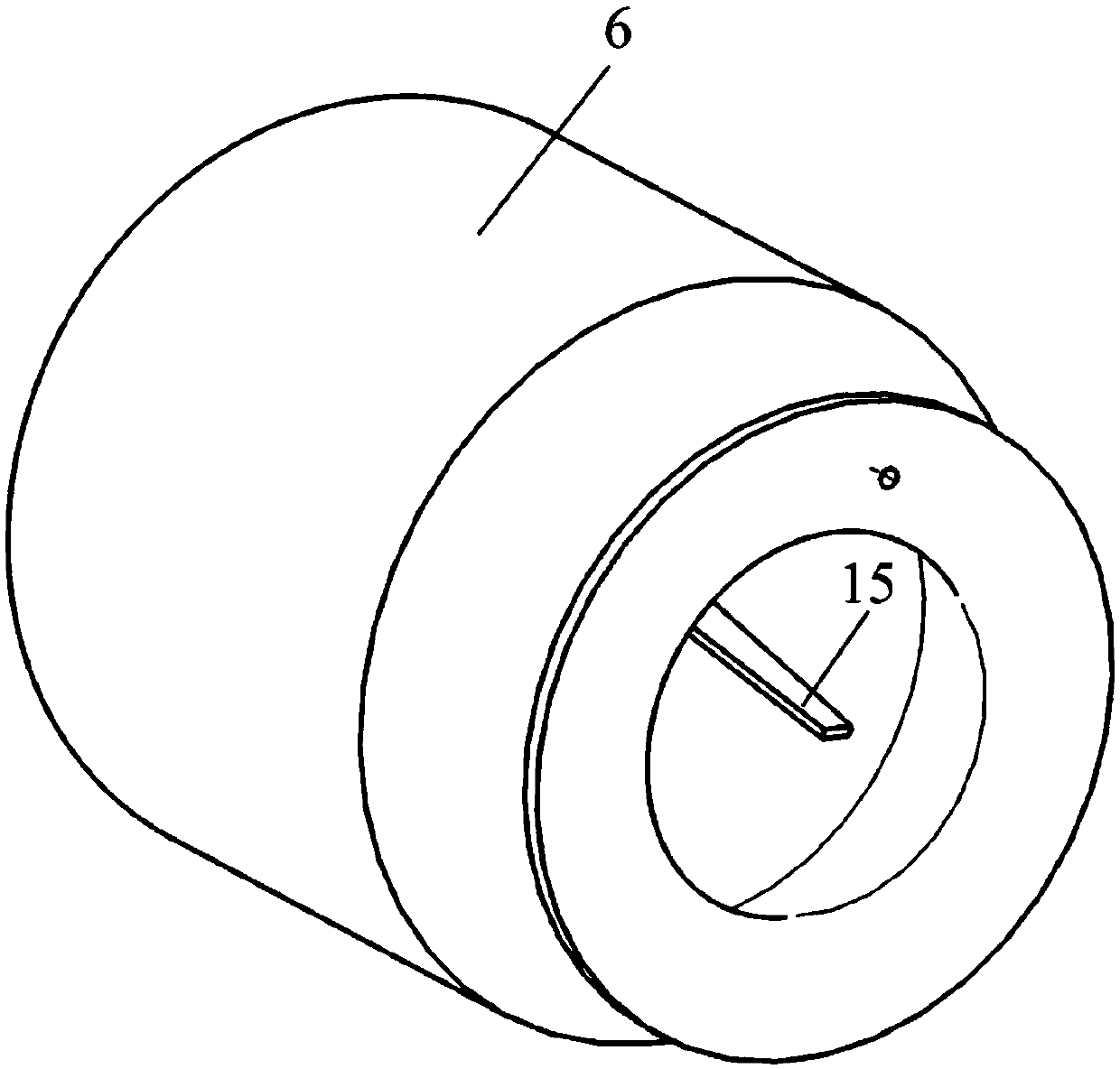

[0024] like Figure 1 to Figure 8 Shown, a kind of uniaxial fire and explosive material mixing device of the present application comprises frame (1), speed reducer 1 (2), end cover (3), swivel frame (4), swivel joint (5), mixer (6), cover (7), shaft seat (8), cylinder (9), guide post (10), rotating arm (11), reducer II (12), bearing I (13), sealing ring (14 ), groove plate (15), bearing II (16), gear I (17), gear II (18), motor (19), rotating shaft I (20), rotating shaft II (21), temperature sensor (22) , sealing cap (23), filter cap (24), bearing III (25), pipeline (26). The mixer (6) is heated by an oil bath mold temperature controller, the heating temperature range is 70°C to 140°C, and the heating temperature is selected according to the characteristics of the material; the reducer I (2) drives the rotating frame (4) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com