Sludge negative-pressure ceramic membrane concentration integrated machine

A technology of ceramic membrane and integrated machine, which is applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of large footprint, low concentration efficiency, unstable concentration, etc. Less land area, high concentration efficiency, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

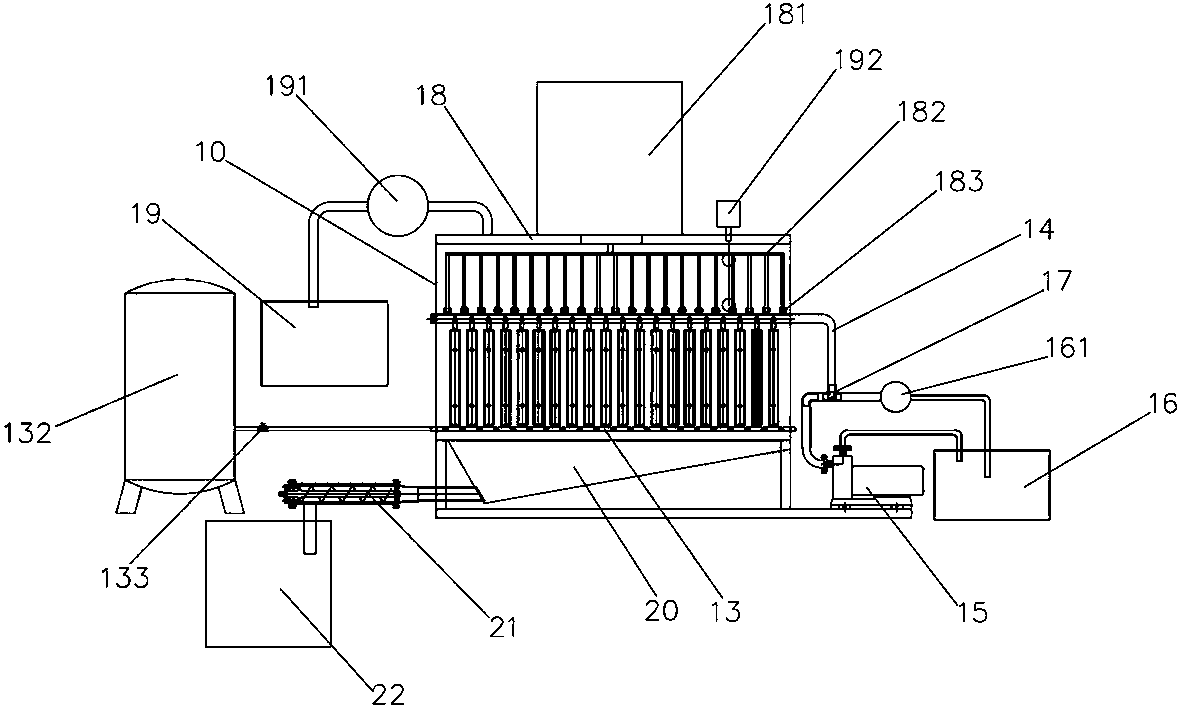

[0026] Embodiment 1, a sludge screw pump 21 is arranged on one side of the sludge hopper 20, and the sludge screw pump 21 is connected to the sludge hopper 20, and a sludge tank 22 is also arranged on the side of the sludge hopper 20, The sludge hopper 20 communicates with the sludge tank 22 through a sludge screw pump 21, and after concentration, the sludge sinks into the sludge bucket 20, and the sludge is sent out to the sludge tank 22 by the sludge screw pump 21;

Embodiment 2

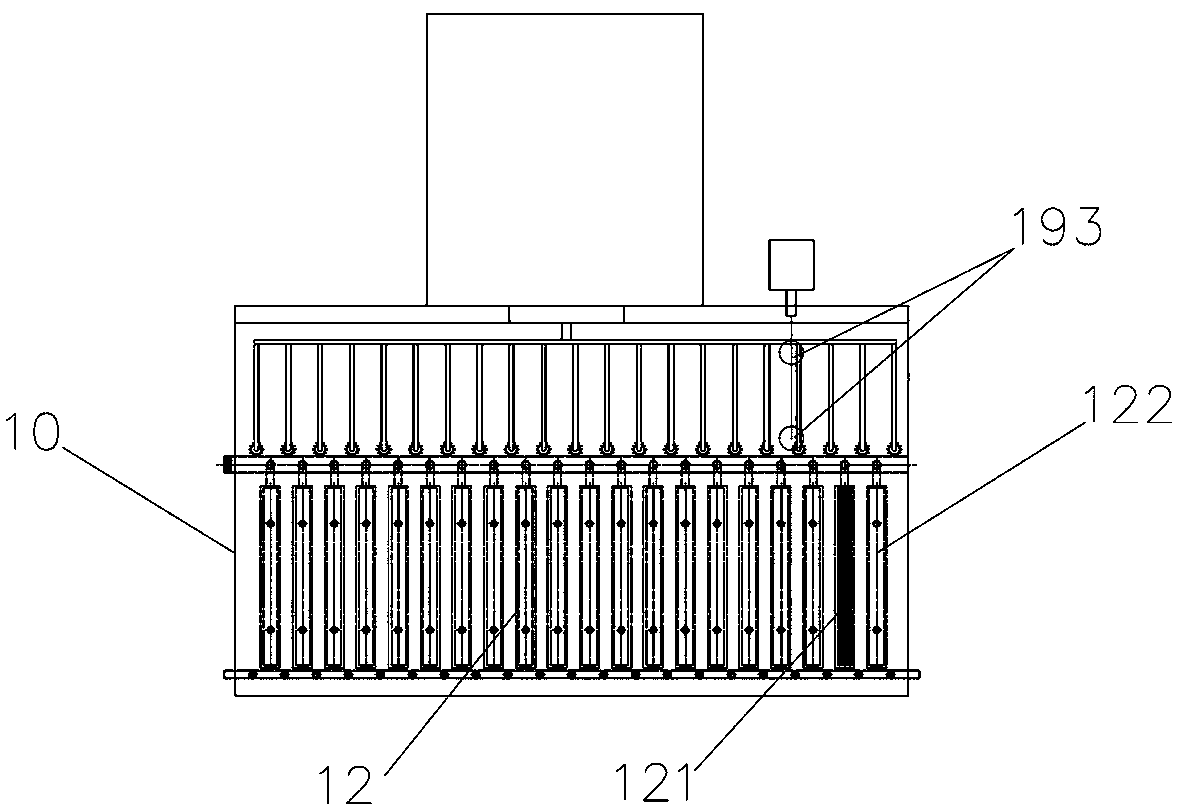

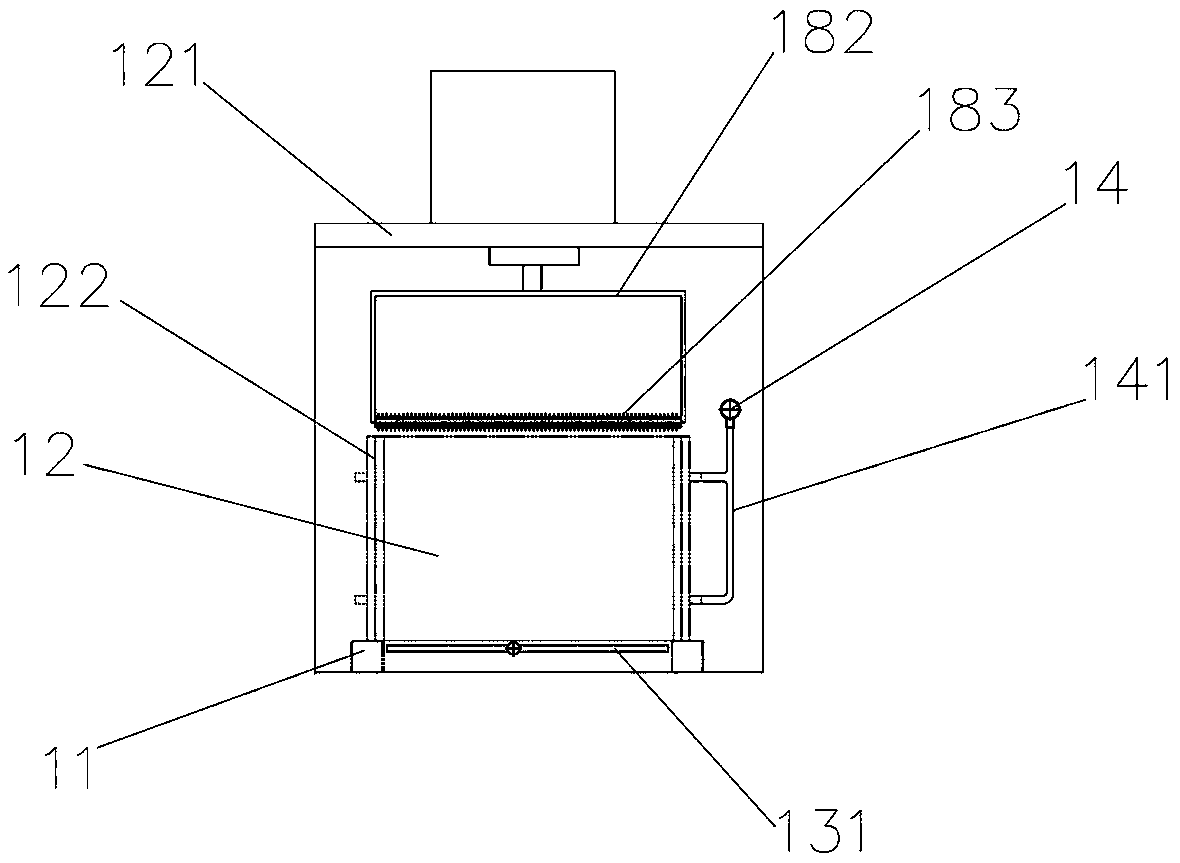

[0027] Embodiment 2, one end of the air outlet pipe 13 is fixed on the side plate of the sewage tank 10, and the other end passes through the side plate of the sewage tank 10 to connect with the gas storage tank 132, and a valve is arranged on the air outlet pipe 13 outside the sewage tank 10 Switch 133, the gas explosion pipe 131 is provided with a plurality of ventilation holes, when the concentrator is working, the valve switch 133 can be opened, and the gas explosion pipe 131 rushes out the high-speed airflow from the ventilation holes, so that the sewage flows on the surface of the nano-ceramic membrane 121, and the water flow is strengthened. Part passes through the efficiency of the nano-ceramic membrane 121;

Embodiment 3

[0028] Embodiment 3, a three-way switching valve 17 is arranged between the filtrate water pipe 14 and the self-priming magnetic drive pump 15 and the clean water pool 16, and the filtrate water pipe 14 is respectively connected to the self-priming magnetic drive pump 15 through the three-way switching valve 17 1. Clean water pool 16, the self-priming magnetic drive pump 15 is connected to the clean water pool 16 through a pipeline, and the negative pressure generated by the self-priming magnetic drive pump 15 absorbs the water in the ceramic plate 12, and the power consumption is low, accounting for Small area, low operating cost, high sludge concentration efficiency;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com