A Time-sharing Driving Mechanism for a Cabin Door and Its Application

A technology of time-sharing drive and hatch door, which is applied in the direction of aircraft accessories, etc., can solve the problems of small initial torque of the driving mechanism, sudden change of handle force, and large handle force of the hatch door, etc., to achieve improved safety, simple mechanism, and simple transmission relationship of the mechanism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

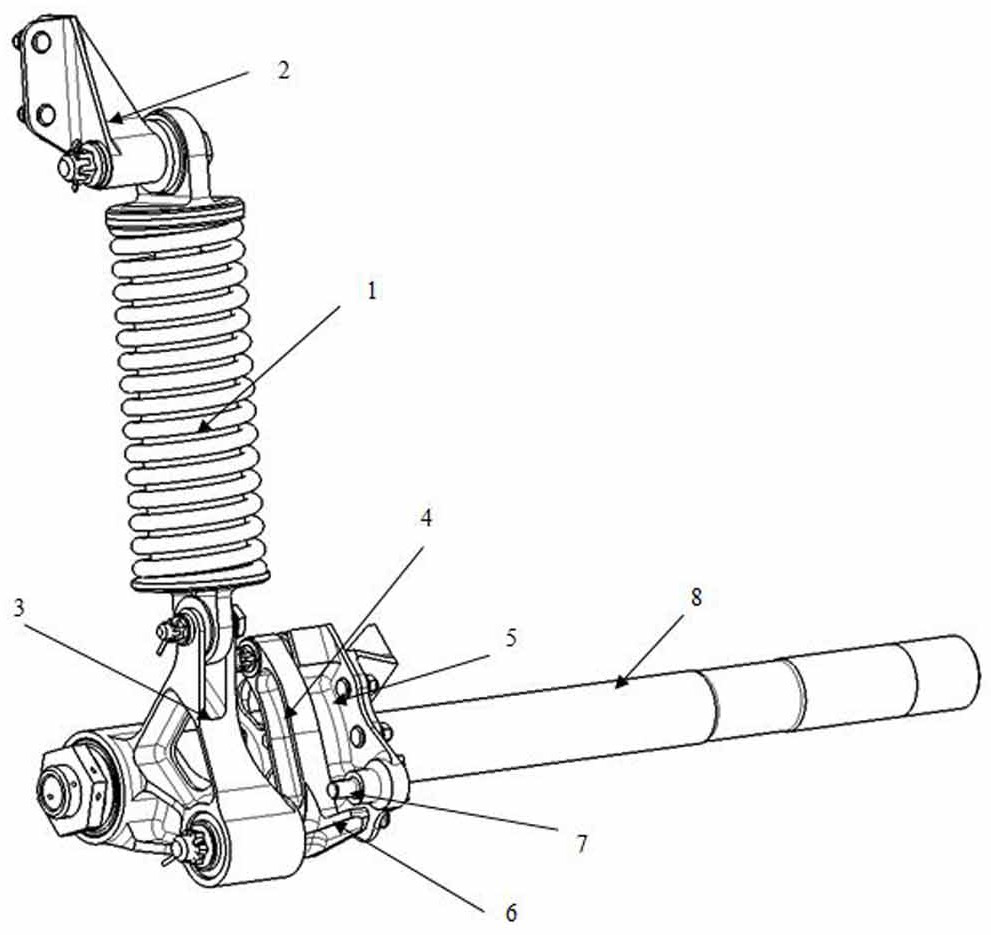

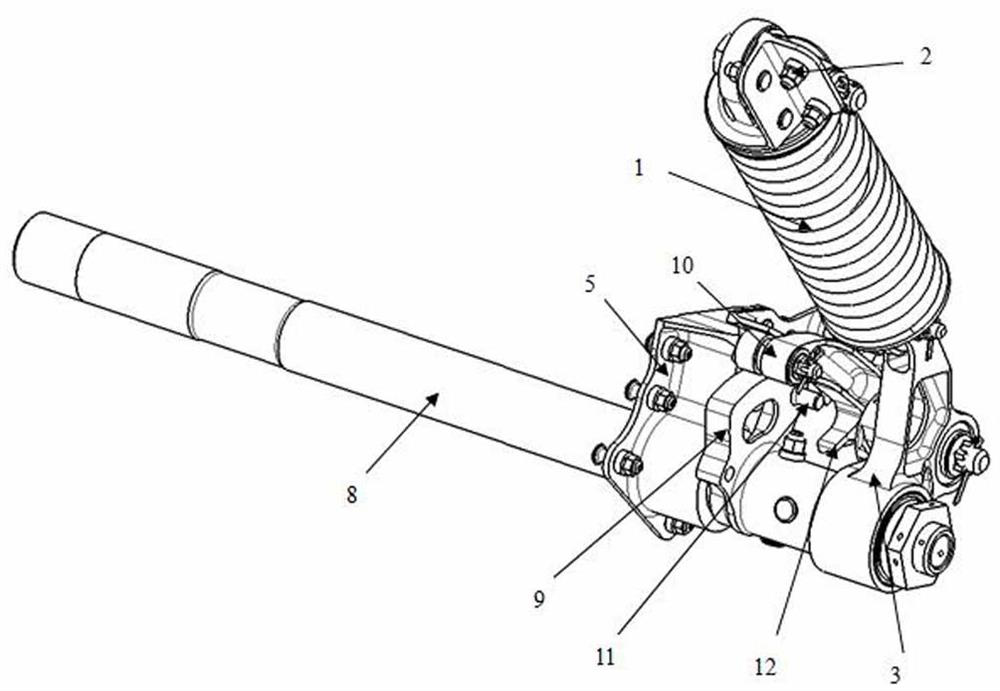

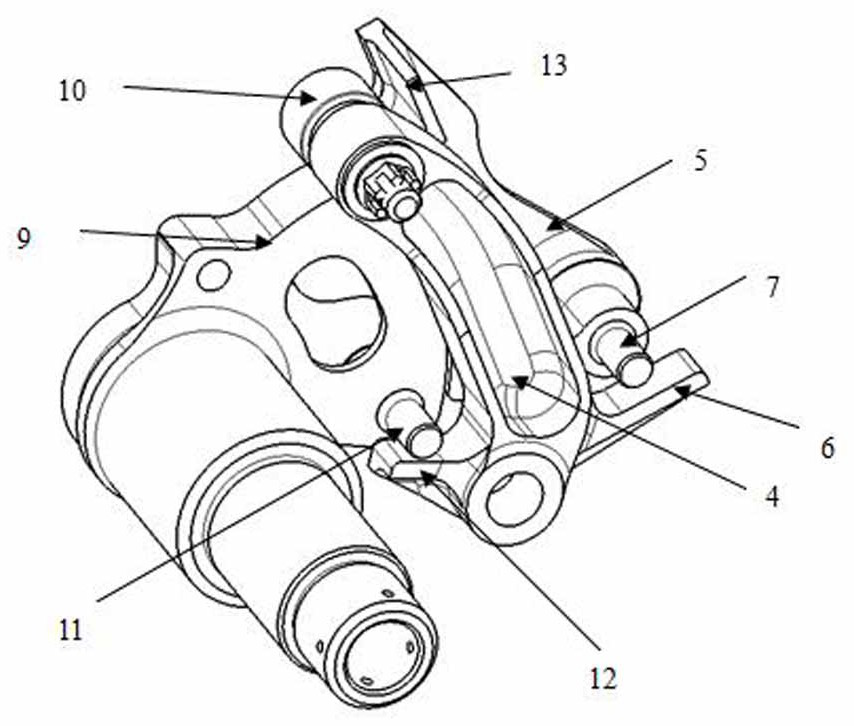

[0017] like figure 1 and figure 2 As shown, a hatch door time-sharing drive mechanism has a support 2 fixedly connected to the hatch structure, the support 2 is hingedly connected to the compression spring assembly 1, the other end of the compression spring assembly 1 is hinged to the crank 3, and the crank 3 is hinged to the crank 3. The rocker arm 4 is hingedly connected, the roller 10 is fixedly connected to the rocker arm 4, the stopper I6 and the stopper II12 are respectively fixedly connected to both sides of the rocker arm 4, the crank 3 is hingedly connected to the handle shaft 8, and the handle shaft 8 is hinged to the hatch structure connect. The handle shaft 8 is fixedly connected with a cam 9, the cam 9 is fixedly connected with a pin II11, the joint 5 is fixedly connected with the hatch structure, and the joint 5 is fixedly connected with a pin I7.

[0018] The joint 5 is provided with a cam groove 13. In the fully closed position of the hatch, the roller 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com