Elastic-rigid coupling regulating and controlling aluminum alloy sheet electron beam welding stress deformation fixture

A technology of electron beam welding and rigid coupling, which is applied in the direction of electron beam welding equipment, welding equipment, welding equipment, etc., can solve problems such as damage, crack defects on the surface of test pieces, and achieve the effect of avoiding large deformation and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

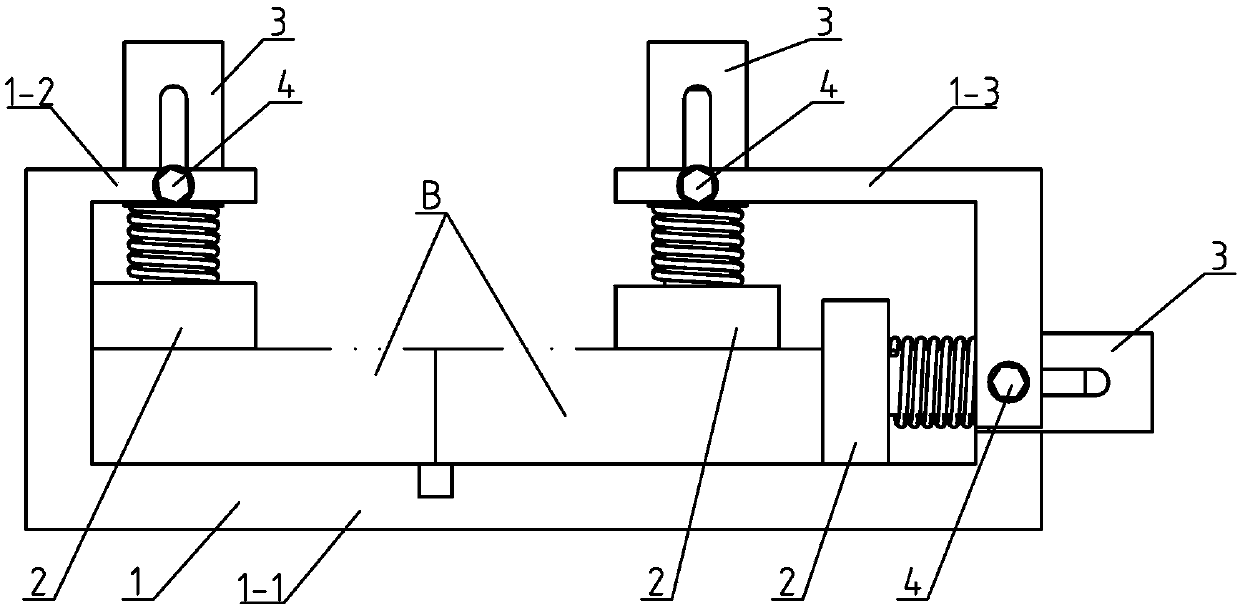

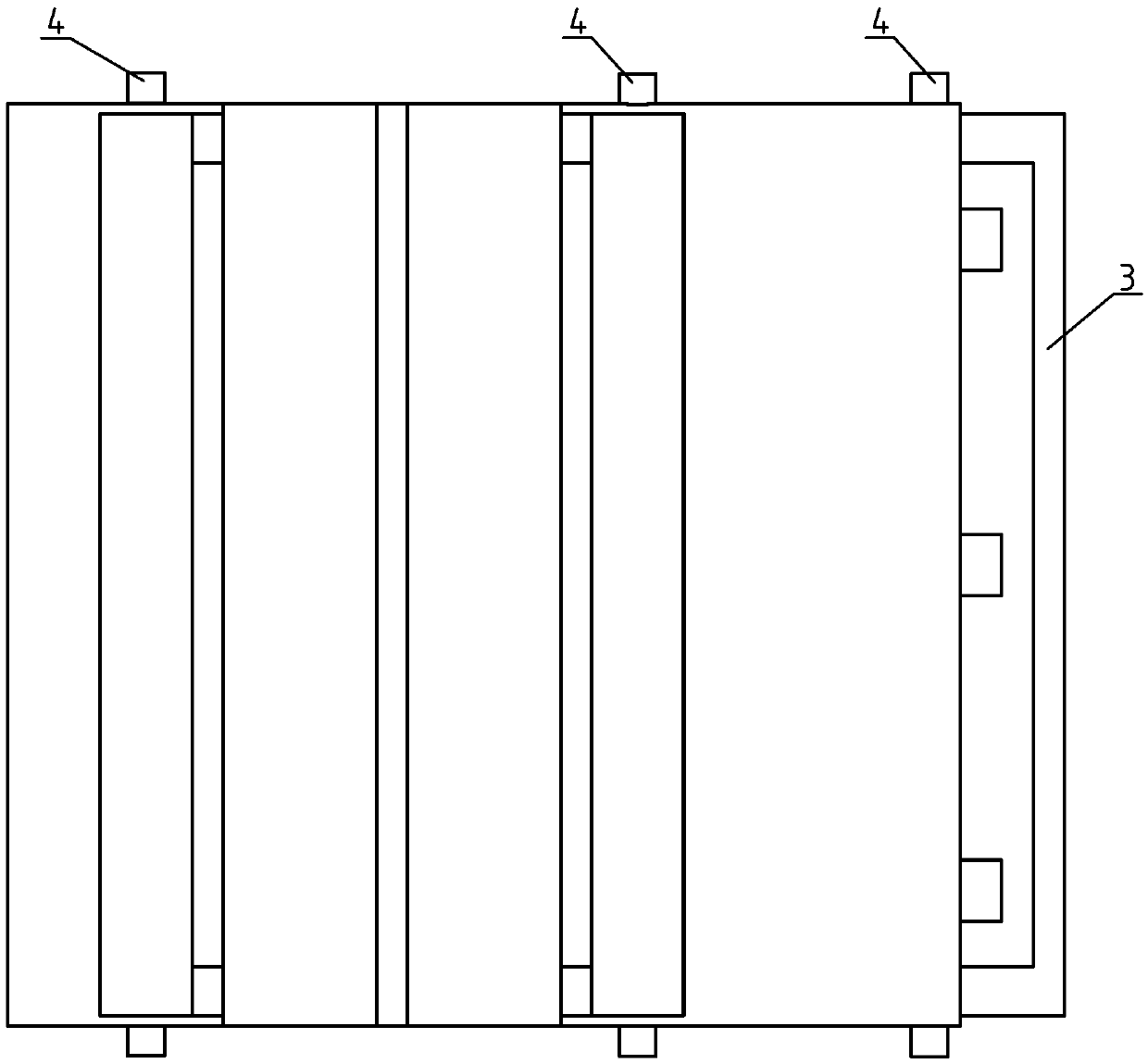

[0023] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, this embodiment is elastic-rigid coupling adjustment plate electron beam welding stress deformation clamp, which includes a clamp shell 1, three restraint devices 2, three restraint baffles 3 and three connection elements 4;

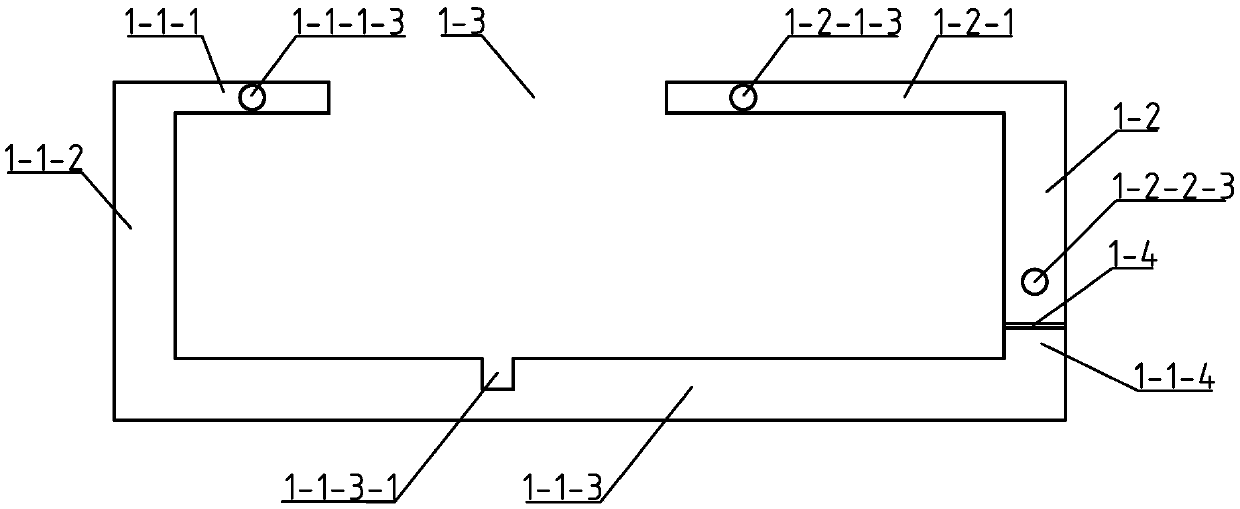

[0024] The fixture shell 1 includes a fixed shell 1-1 and a movable shell 1-2, the movable shell 1-2 and the fixed shell 1-1 form a rectangular frame, the upper end of the rectangular frame is provided with an opening 1-3, the movable shell 1-2 is connected with the fixed shell 1-1 There is a distance (1-4) at the contact point of the fixed shell 1-1, and the distance 1-4 is 1 mm to 2 mm;

[0025] The two ends of the left upper end plate 1-1-1 of the fixed shell 1-1 are respectively provided with textured clamps A, and the left upper end plate 1-1-1 is provided with several left restraining head installation holes 1-1-1 -2, several left restraining head insta...

specific Embodiment approach 2

[0044] Specific implementation mode two: combination Figure 5 Describe this embodiment, the constraining device 2 of this embodiment is composed of a base plate 2-1, several constraining heads 2-2 and several high-strength springs 2-3, and several constraining heads 2-2 are arranged vertically on the base plate 2-2. 1, a high-strength spring 2-3 is set on each constraint head 2-2. The high-strength springs 2-3 are divided into two types: horizontal and vertical, of which there are 3 in the horizontal direction and 6 in the vertical direction, totaling 9. The natural length L of the spring is 25.5mm-60.3mm, the maximum shrinkage △L=10mm, the elastic coefficient K=125N / mm, and the maximum elastic force F=K×△L=125×10=1250N. The maximum force F available in the horizontal direction max It is determined by the maximum shrinkage of the spring (when the length, width and height of the fixture are 150mm×155mm×55mm, and when welding an aluminum plate with a thickness of 100mm×50mm×5...

specific Embodiment approach 3

[0045] Specific implementation mode three: combination image 3 To illustrate this embodiment, the upper end surface of the lower plate 1-1-3 of the fixed housing 1-1 of this embodiment is provided with a groove 1-1-3-1, and the size of the groove 1-1-3-1 is 5mm ×5mm, the groove 2-1-1 can prevent the electron beam from penetrating the sample and acting on the fixture, and protect the fixture bottom plate 2-1. Other components and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Natural length | aaaaa | aaaaa |

| Elastic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com