A preparation method of ordered phase iron-platinum nanoparticles and cobalt-platinum nanoparticles

A nanoparticle, ordered phase technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of no large-scale preparation of ordered phase FePt/CoPt nanoparticles, high preparation cost, Process complexity and other problems, to achieve the effect of easy large-scale production, high cost and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

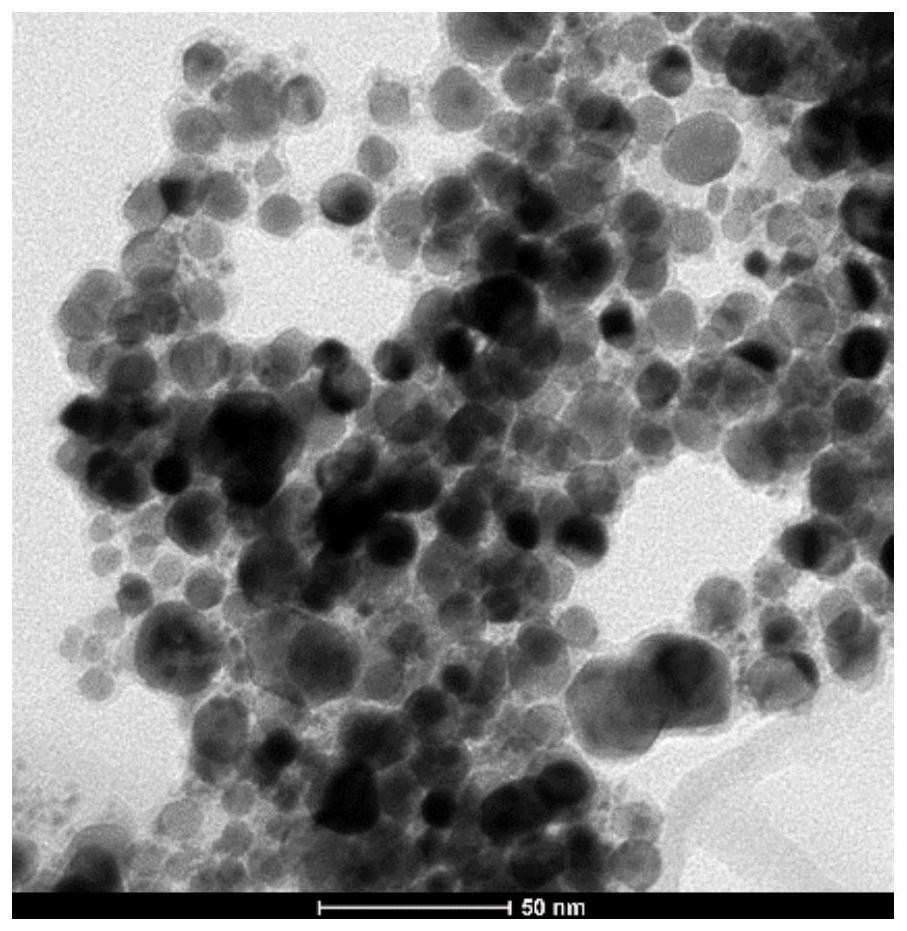

Embodiment 1

[0032] Example 1: Use equimolar amounts of iron acetylacetonate and chloroplatinic acid to configure an ethanol solution with a concentration of 0.1 mol / L, impregnate the sodium chloride powder, remove the excess impregnating liquid, and then dry the powder. The dried powder is reduced with hydrogen at 800°C, washed with water, and dried to obtain iron-platinum nanoparticles in an ordered phase.

Embodiment 2

[0033] Example 2: Equimolar iron acetylacetonate and chloroplatinic acid are used to form an ethanol solution with a concentration of 0.01 mol / L, and the sodium chloride powder is impregnated. After removing excess impregnating liquid, the powder is dried. The dried powder is reduced with hydrogen at 800°C, washed with water, and dried to obtain iron-platinum nanoparticles in an ordered phase.

Embodiment 3

[0034] Example 3: Use equimolar amounts of iron acetylacetonate and chloroplatinic acid to configure an ethanol solution with a concentration of 1 mol / L, impregnate the sodium chloride powder, remove the excess impregnating liquid, and dry the powder. The dried powder is reduced with hydrogen at 800°C, washed with water, and dried to obtain iron-platinum nanoparticles in an ordered phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com