Fodder mixing device for livestock rearing

A mixing device and feed technology, applied in feed, mixer, mixing method, etc., can solve the problems of nutrient loss in feed additives, achieve the effect of improving mixing effect, avoiding blockage, and improving breeding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

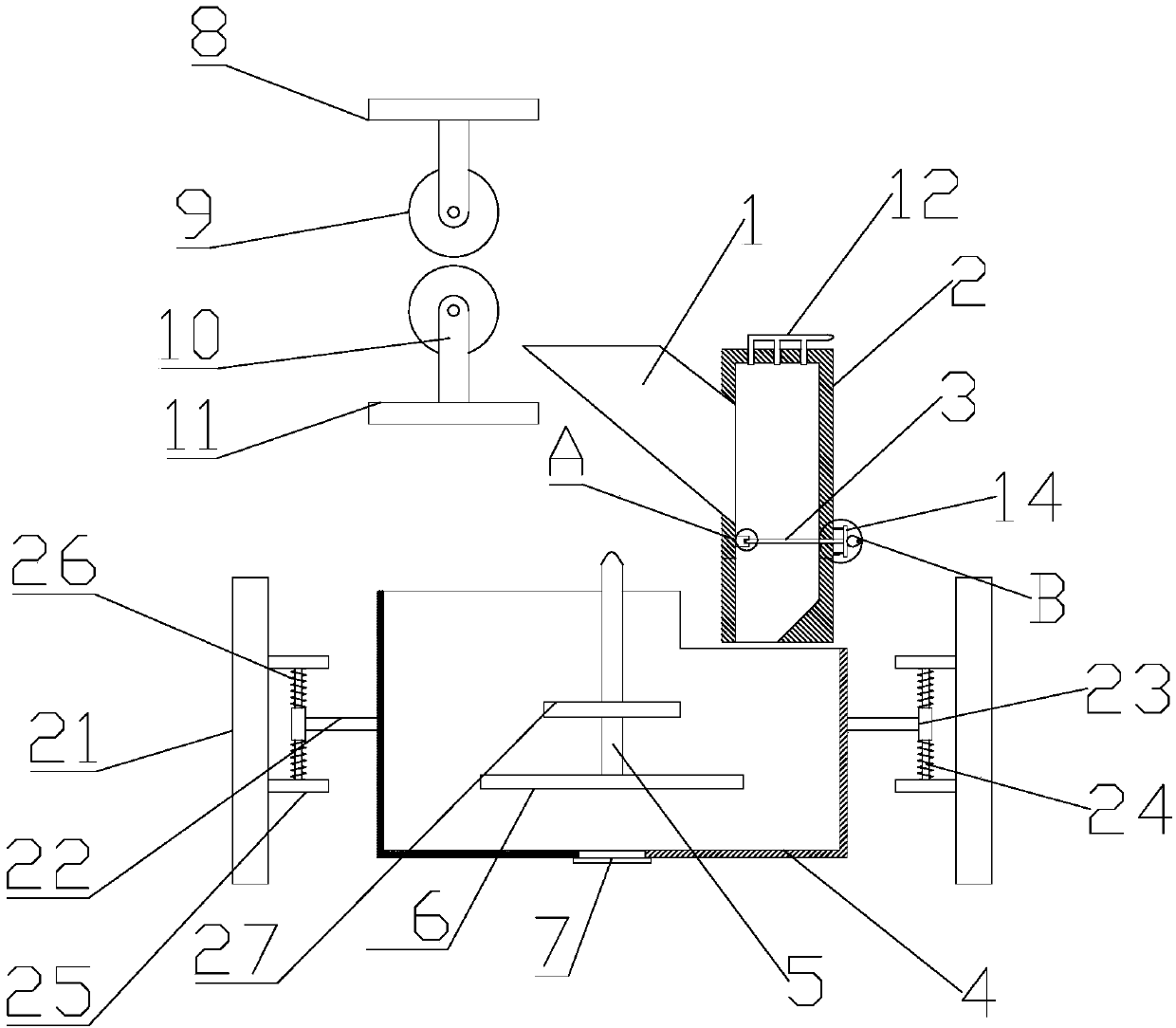

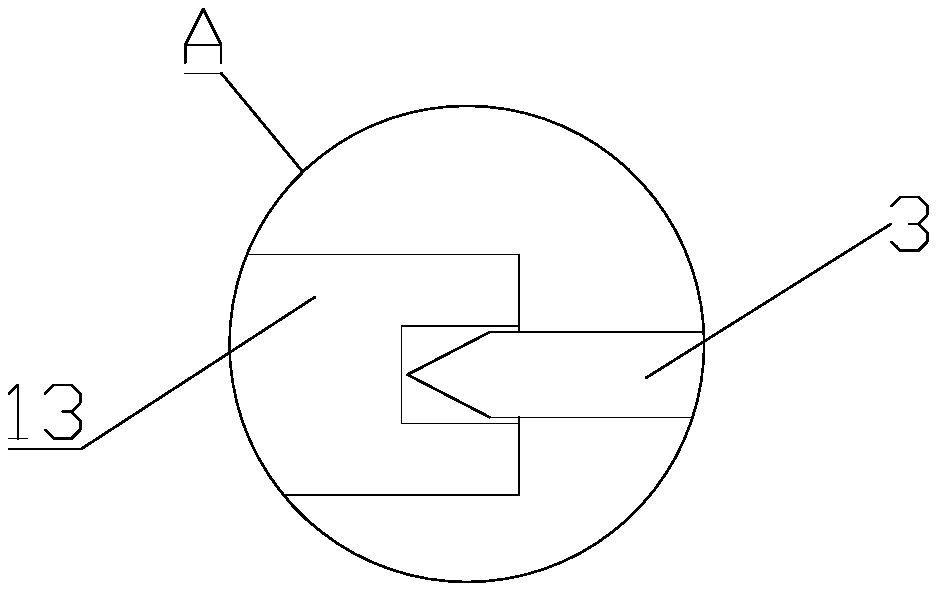

[0018] see figure 1 and figure 2 , a feed mixing device for animal husbandry, comprising a hopper 1, a cutting box 2, a cutting knife 3, a mixing box 4, a mixing shaft 5, a mixing arm 6, a discharge port 7 and a water squeezing mechanism 8, and the water squeezing mechanism 8 is right The hopper 1 is arranged on the side, and the cutting box 2 is arranged on the right side of the hopper 1. The hopper 1 communicates with the cutting box 2, and the cutting knife 3 is installed inside the cutting box 2. The mixing box 4 is arranged below the cutting box 2, the mixing shaft 5 is arranged in the mixing box 4, the mixing arm 6 is welded and fixed on the bottom of the mixing shaft 5, and the bottom of the mixing box 4 is provided with a The discharge port 7 is described; the water squeezing mechanism 8 includes a squeeze roller 9, a roller mounting frame 10 and a top plate 11, and the number of the squeeze rollers 9 is two, and the two squeeze rollers 9 are placed up and down, and ...

Embodiment 2

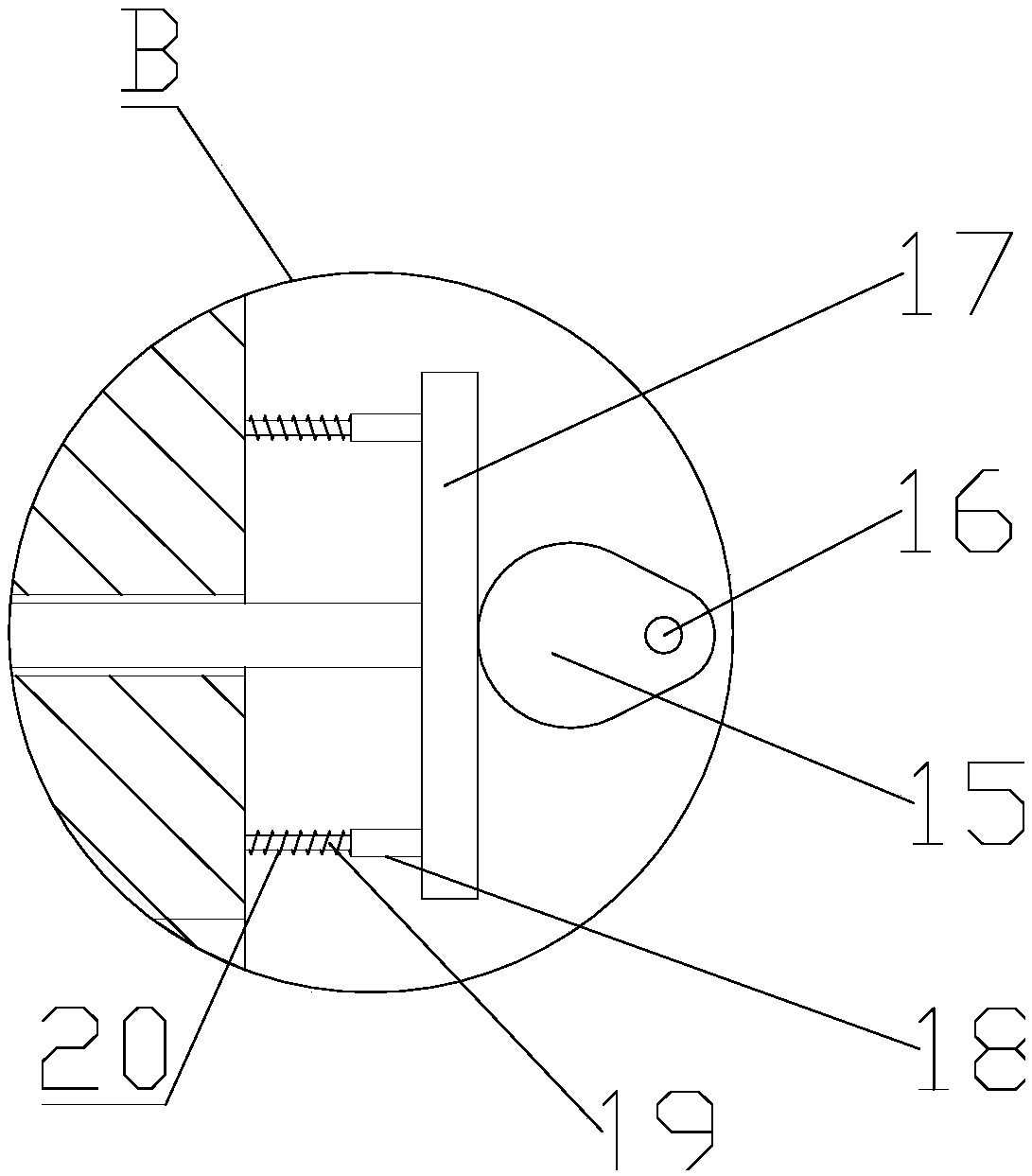

[0020] see figure 1 and image 3 , the pushing mechanism 14 includes a cam 15, a camshaft 16, a push plate 17, a sleeve 18, a slide bar 19 and a spring A20, and the cam 15 is welded and fixed on the camshaft 16, and the cam 15 and the The push plate 17 is in close contact with the left end surface of the push plate 17 and the right end of the sleeve 18 is welded and fixed, and a slide bar 19 is slidably installed in the sleeve 18, and the left end of the slide bar 19 is welded and fixed on the cut-off plate. On the outer wall of the box 2, the slide bar 19 is also covered with a spring A20.

[0021] The working principle of the present invention is: the green fodder passes between the upper and lower two squeeze rollers 9, and is extruded by the upper and lower two squeeze rollers 9, thereby playing the technical effect of fully squeezing water; the green fodder through squeezing water enters the described cutting box 2 Inside, the top of the cutting box 2 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com