Preparation method of ultra-low-pressure and high-flux metal-organic nano particle assembly nanofiltration membrane

A nanoparticle assembly, metal-organic technology, applied in nanotechnology, chemical instruments and methods, membranes, etc., can solve the problem of poor stability of the separation layer and support layer, increase the frequency of membrane cleaning and replacement, and reduce membrane permeability selectivity, etc. problem, achieve good industrial application prospects, simple method, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

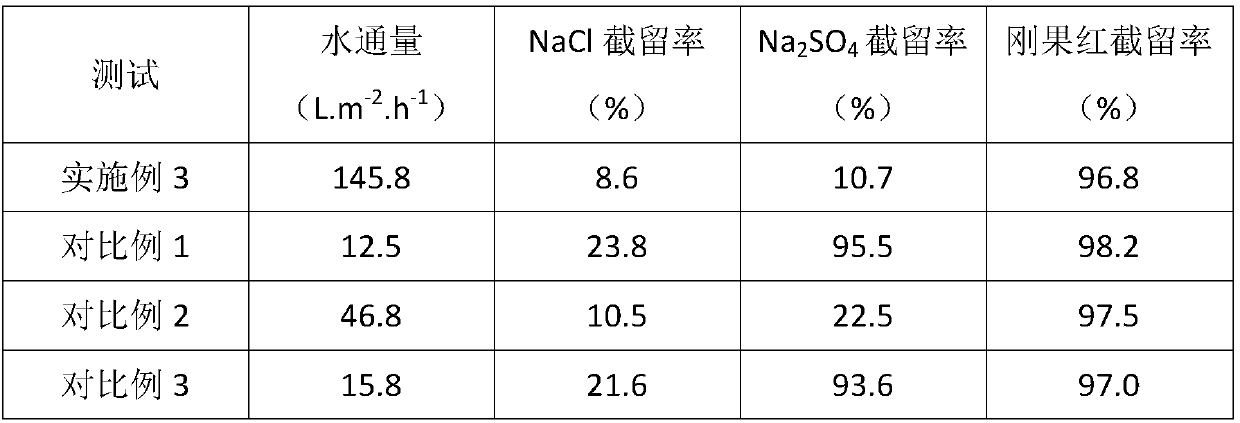

Examples

preparation example Construction

[0014] A method for preparing a nanofiltration membrane assembled with ultra-low pressure and high flux metal-organic nanoparticles, comprising the following steps:

[0015] (1) Dissolving 0.1 to 3 parts by mass of polyamine molecules, 0.1 to 1 parts by mass of metal salts and 0.05 to 0.25 parts by mass of dopamine in 100 parts by mass of an alkaline aqueous solution, and passing oxygen into it for oxidative polymerization, Obtain an aqueous dispersion of organic nanoparticle seeds loaded with metal ions;

[0016] (2) Immerse the porous support membrane in the above-mentioned aqueous dispersion of nanoparticle seeds at 15 to 25°C for 10 to 60 minutes, take out and remove the excess aqueous dispersion on the surface of the membrane, self-assemble the nanoparticles into a membrane, and then use organic The ligand solution is impregnated, and the nanoparticles grow in situ to form a nascent film assembled by metal-organic nanoparticles;

[0017] (3) Interfacially cross-link the ...

Embodiment 1

[0021] Get 0.1g piperazine, 0.1g zinc nitrate and 0.05g dopamine and dissolve in 100g mass percentage concentration and be 0.01wt% sodium hydroxide aqueous solution, feed oxygen, polymerize at 15 ℃ for 8 hours, obtain the organic nanoparticle of loading zinc ion Seed water dispersion, immerse the polysulfone ultrafiltration membrane in the above water dispersion at 15°C for 60 minutes, take out and remove the excess water dispersion on the surface of the membrane, the nanoparticle seeds self-assemble into a film, and then use the mass percentage concentration of 0.2% 2-methylimidazole methanol solution was soaked at 25°C for 0.5 hour, and the nanoparticles grew in situ to form a nascent film assembled by metal-organic nanoparticles. The interfacial crosslinking reaction was carried out at 15° C. for 10 minutes in n-hexane trimelliticoyl chloride solution, solidified at 45° C. for 30 minutes, and washed with deionized water to obtain a nanofiltration membrane assembled with meta...

Embodiment 2

[0024] Take 1g of m-phenylenediamine, 1g of zinc nitrate and 0.25g of dopamine and dissolve them in 100g of a mass percent concentration of 0.1wt% sodium hydroxide aqueous solution, feed oxygen, and polymerize at 25°C for 0.5 hours to obtain organic nanoparticles loaded with zinc ions Seed water dispersion, immerse the polysulfone ultrafiltration membrane in the above water dispersion at 25°C for 10 minutes, take out and remove the excess water dispersion on the surface of the membrane, the nanoparticle seeds self-assemble into a film, and then use the mass percentage concentration of 4% 2-methylimidazole methanol solution was immersed at 15°C for 6 hours, and the nanoparticles grew in situ to form a nascent film assembled by metal-organic nanoparticles. In the benzenetricarboxylic acid chloride n-hexane solution, the interfacial crosslinking reaction was carried out at 25° C. for 1 minute, solidified at 65° C. for 10 minutes, and washed with deionized water to obtain a nanofil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com