Filtering device for sweet potato starch production

A filtration device and technology of sweet potato starch, applied in filtration separation, moving filter element filter, separation method, etc., can solve problems such as affecting filtration effect, incomplete filtration, cleaning, etc., and achieve easy detection and maintenance, complete filtration, and filtration. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

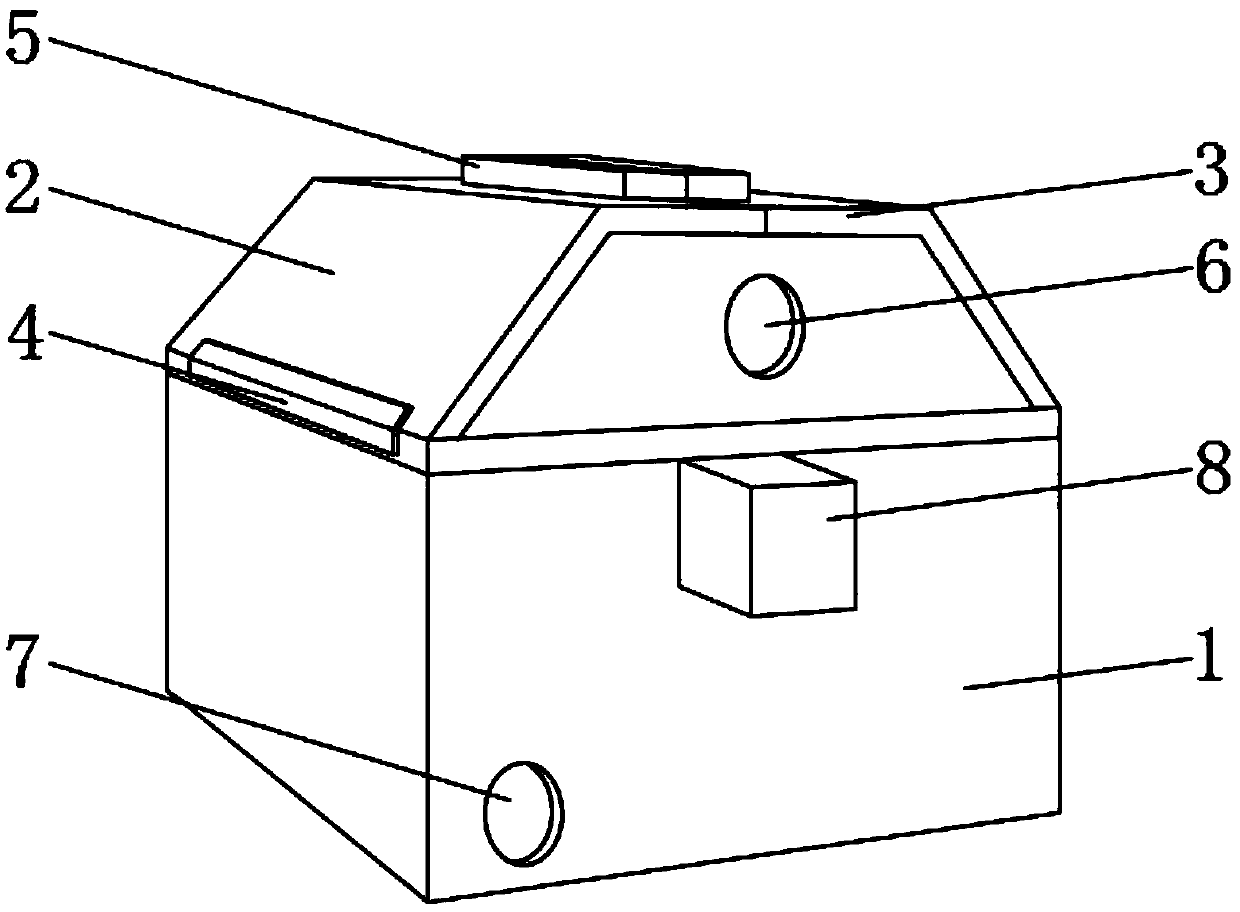

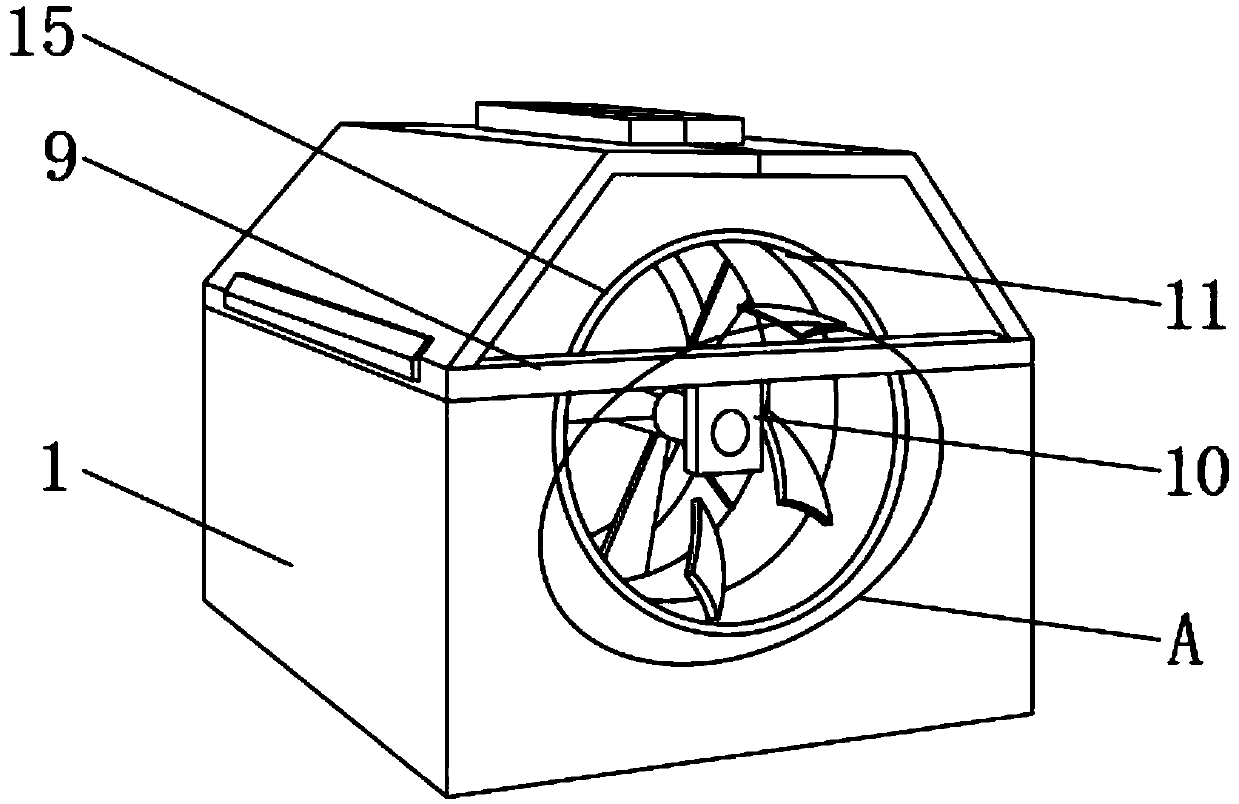

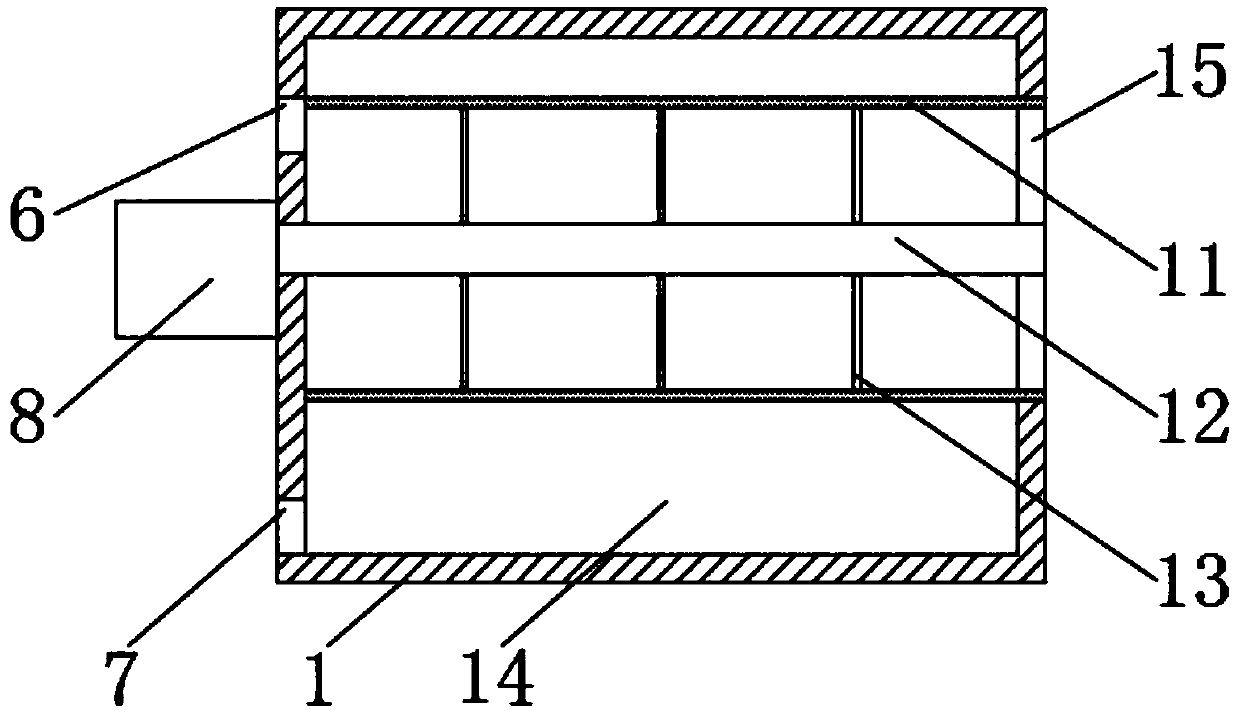

[0026] Such as Figure 1-5 As shown, a filter device for sweet potato starch production includes a main body shell 1, a crossbeam 9 is fixedly installed on the rear end of the main body shell 1, a mounting seat 10 is fixedly installed on the lower end of the crossbeam 9, and a motor box is fixedly installed on the front end of the main body shell 1 8, and the motor box 8 and the mounting base 10 are located at the same level, the interior of the motor box 8 and the mounting base 10 is provided with a rotating shaft 12, and the outer surface of the rotating shaft 12 is fixedly installed with several sets of mounting rods 13, several sets of mounting rods 13 A sieve drum 11 is fixedly installed on the outer surface of the circumference of the main body shell 1, and the front end outer surface of the main body shell 1 is provided with a feed port 6 and a discharge port 7, and the feed port 6 is located at the upper end of the main body shell 1, and the discharge port 7 is located ...

Embodiment 2

[0028] Such as Figure 1-5 As shown, a filter device for sweet potato starch production includes a main body shell 1, a crossbeam 9 is fixedly installed on the rear end of the main body shell 1, a mounting seat 10 is fixedly installed on the lower end of the crossbeam 9, and a motor box is fixedly installed on the front end of the main body shell 1 8, and the motor box 8 and the mounting base 10 are located at the same level, the interior of the motor box 8 and the mounting base 10 is provided with a rotating shaft 12, and the outer surface of the rotating shaft 12 is fixedly installed with several sets of mounting rods 13, several sets of mounting rods 13 A sieve cylinder 11 is fixedly installed on the outer surface of the circumference of the main shell 1, and the upper end of the main body shell 1 is respectively provided with a No. 1 movable door 2 and a No. 2 movable door 3, and the No. 1 and No. 1 movable door 2 and No. 2 movable door 3 are all provided with hinges 4, an...

Embodiment 3

[0030] Such as Figure 1-5 As shown, a filter device for sweet potato starch production includes a main body shell 1, a crossbeam 9 is fixedly installed on the rear end of the main body shell 1, a mounting seat 10 is fixedly installed on the lower end of the crossbeam 9, and a motor box is fixedly installed on the front end of the main body shell 1 8, and the motor box 8 and the mounting base 10 are located at the same level, the interior of the motor box 8 and the mounting base 10 is provided with a rotating shaft 12, and the outer surface of the rotating shaft 12 is fixedly installed with several sets of mounting rods 13, several sets of mounting rods 13 A sieve drum 11 is fixedly installed on the outer surface of the circumference of the main body shell 1, and the front end outer surface of the main body shell 1 is provided with a feed port 6 and a discharge port 7, and the feed port 6 is located at the upper end of the main body shell 1, and the discharge port 7 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com