Pipeline protection structure of road construction, and mounting method thereof

A technology for pipeline protection and road construction, which is applied in the direction of cable installation, cable installation in ground conduits, and cable installation devices. It can solve problems such as pipeline damage, reduce pipeline damage, save labor, and avoid wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

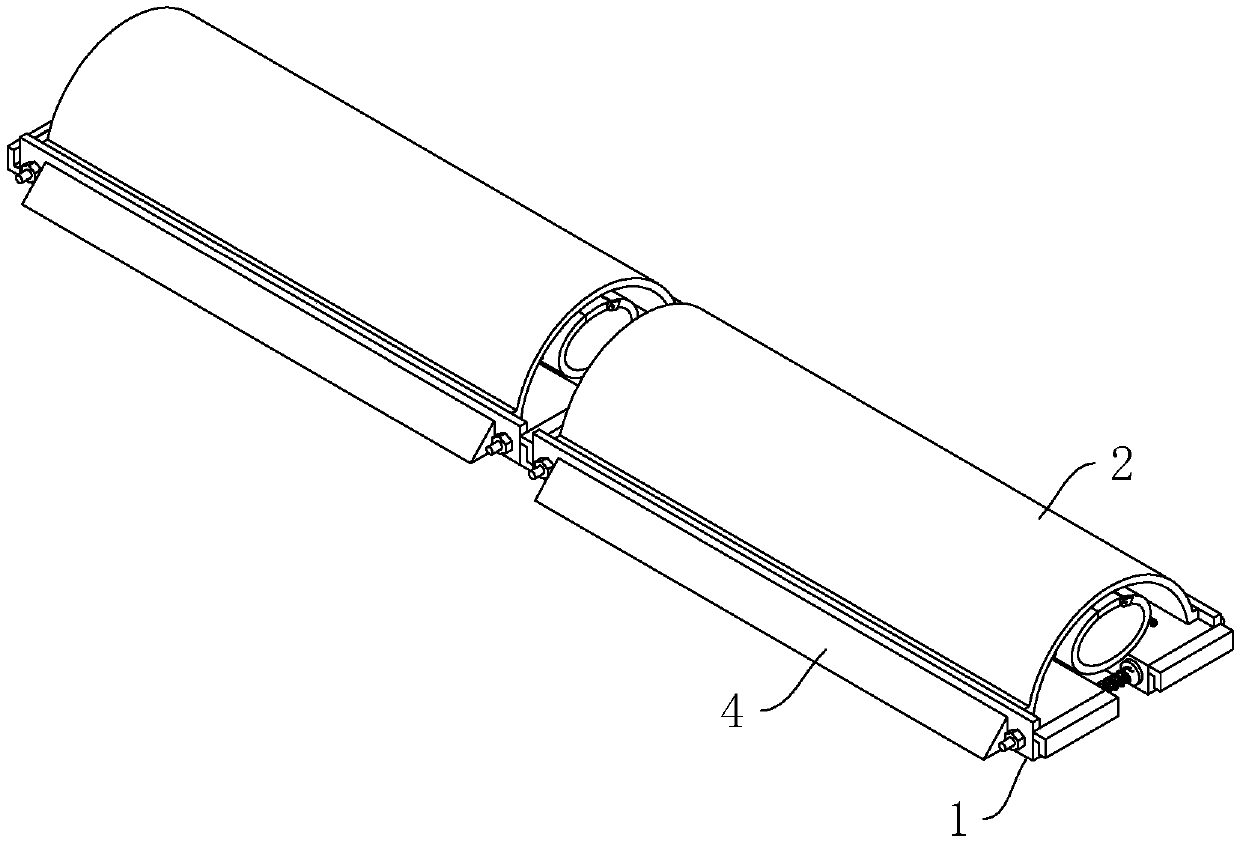

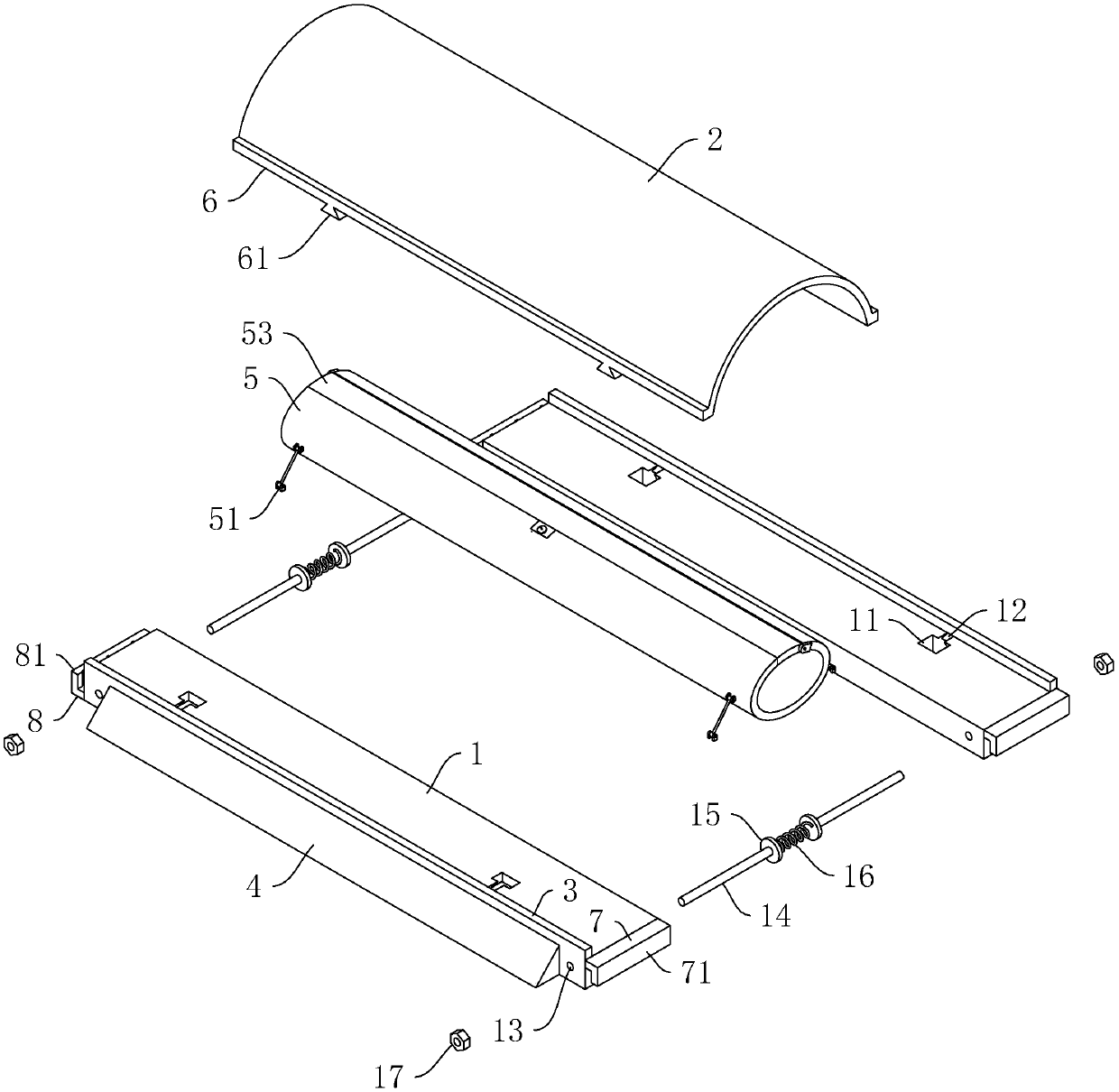

[0044] Embodiment 1: as figure 1 , figure 2 As shown, a pipeline protection structure for road construction includes a pair of bases 1 and a support plate 2 arranged on the pair of bases 1 . Support blocks 3 are vertically provided on the upper end surfaces of the sides of the base 1 facing away from each other, and inclined slopes 4 are provided on the outer side walls of the base 1 .

[0045] Such as figure 2 As shown, the structure also includes a protective cover 5 , a pair of pull rods 51 are hinged to the sidewall of the lower end of the protective cover 5 , and the lower ends of the pair of pull rods 51 are respectively hinged to the upper end surfaces of the pair of bases 1 .

[0046] Such as figure 2 As shown, the support plate 2 is in an arch shape, and both ends of the support plate 2 are provided with mounting blocks 6 . Both ends of the lower end surface of the mounting block 6 are provided with a dovetail block 61, and the upper end surface of the base 1 i...

Embodiment 2

[0066] Embodiment 2: An installation method for installing the above-mentioned pipeline protection structure, comprising the following steps:

[0067] S1, put a pair of bases 1 flat on the road, and make the sides with slopes 4 away from each other;

[0068] S2, splicing multiple sets of bases 1 according to the width of the road surface;

[0069] S3, place the limit rod 14 between the pair of bases 1, and then insert the ends of the pair of limit rods 14 away from each other into the limit holes 13 on the pair of bases 1;

[0070] S4, the pipeline is installed inside the protective cover 5;

[0071]S5, placing the mounting plate on the base 1, and inserting the dovetail block 61 on the lower end surface of the mounting block 6 into the dovetail groove 12 on the base 1;

[0072] S6, pushing a pair of bases 1 close to each other, at this time, the dovetail block 61 slides along the inner wall of the dovetail groove 12;

[0073] S7, until the inner side wall of the base 1 col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com