Darkfield Polarization Imaging Method for Classification of Dimples and Dust Defects on Optical Surfaces

A polarization imaging and optical surface technology, which is applied in the direction of optical testing of flaws/defects, material analysis and material analysis through optical means, can solve problems such as differences in light polarization state modulation and classification accuracy limitations, and achieve classification accuracy Improve and improve the effect of advanced optical manufacturing ultra-precision processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

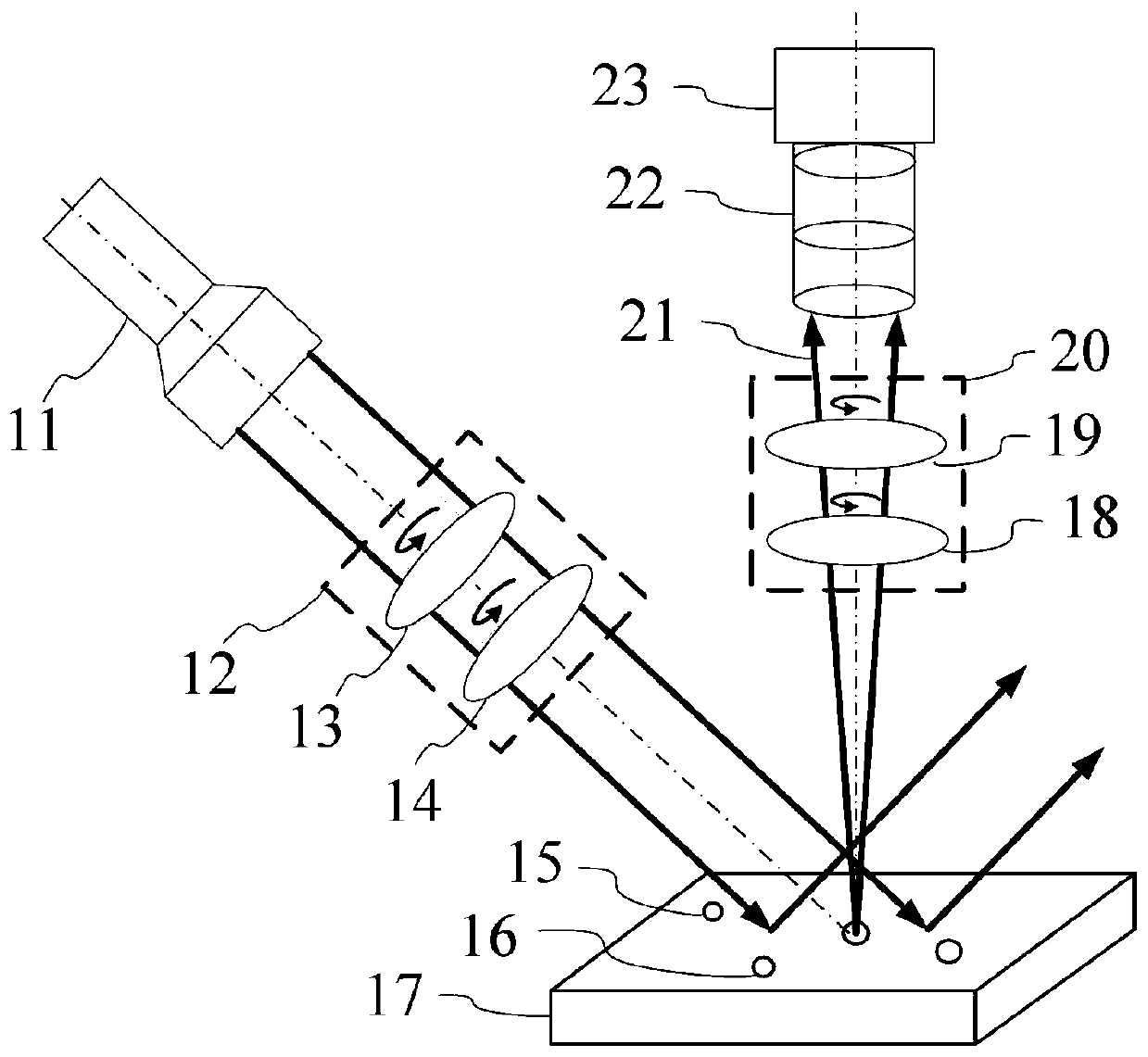

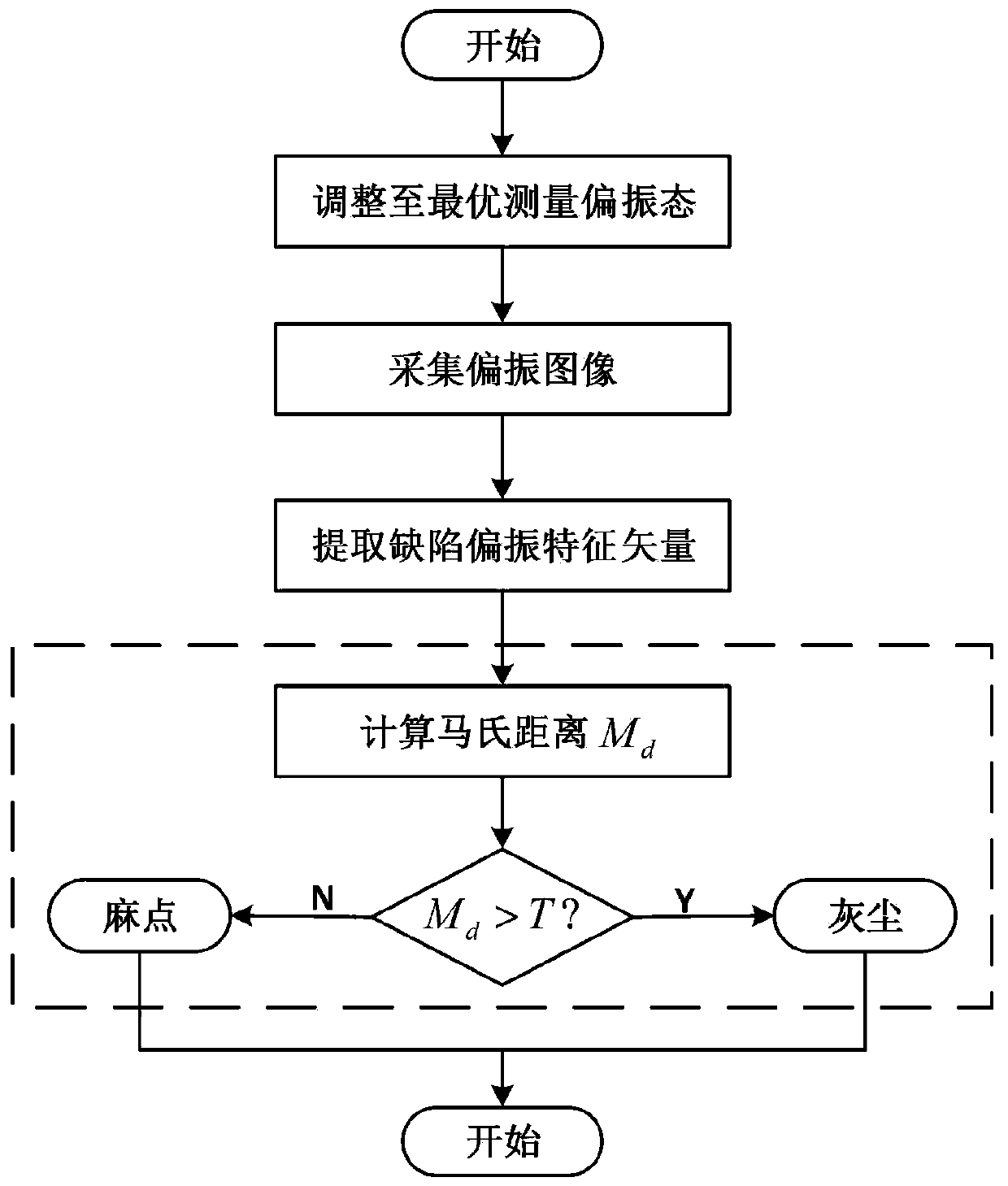

[0037] Below, embodiment 1 of the present invention will use Figure 1-7 to describe in detail.

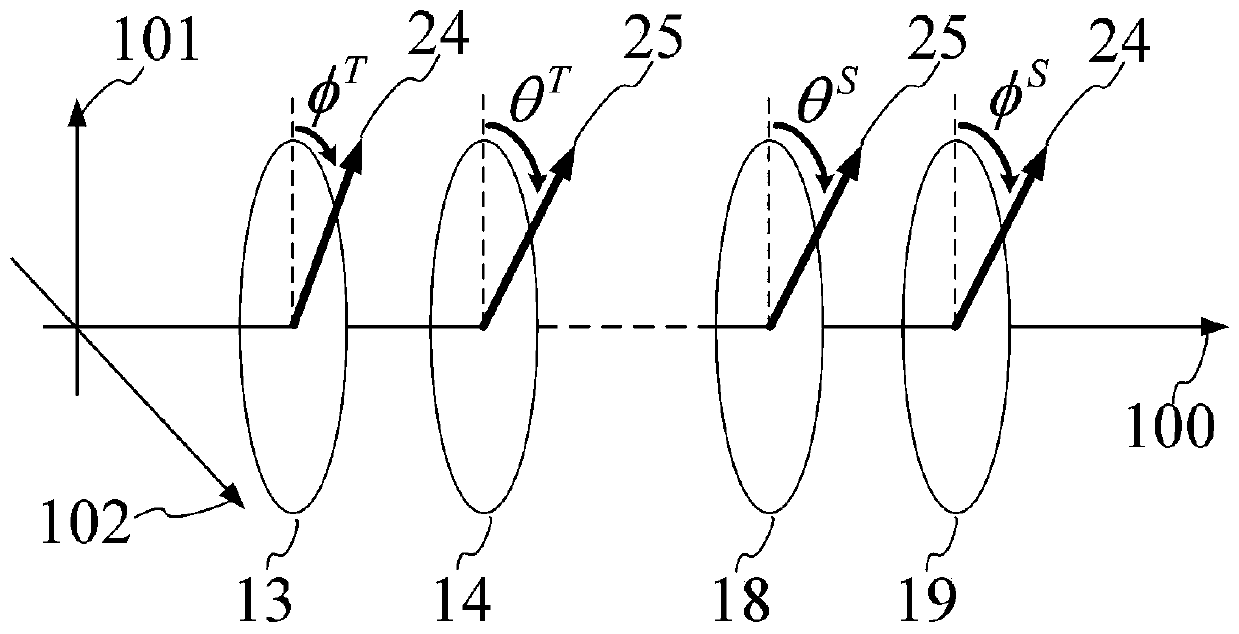

[0038] Such as figure 1 As shown, the dark field polarization imaging device includes a narrowband parallel light source 11 , a polarization state generator (PSG) 12 , a polarization state analyzer (PSA) 20 , a microscope 22 and a CCD 23 . Both PSG12 and PSA20 are composed of a quarter-wave plate 14, 18 and a linear polarizing plate 13, 19 that can rotate around the central axis. The working wavelength of the wave plate is the same as the central wavelength of the light source, both of which are 550nm. The parallel illumination light is emitted from the parallel light source 11 , passes through the PSG 12 to obtain a polarization state, and obliquely enters the optical element 17 at a certain angle. When there are defects on the surface of the component, such as pits 15 or dust 16, the polarization state of the light is modulated and scattered into the PSA 20 for further analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com